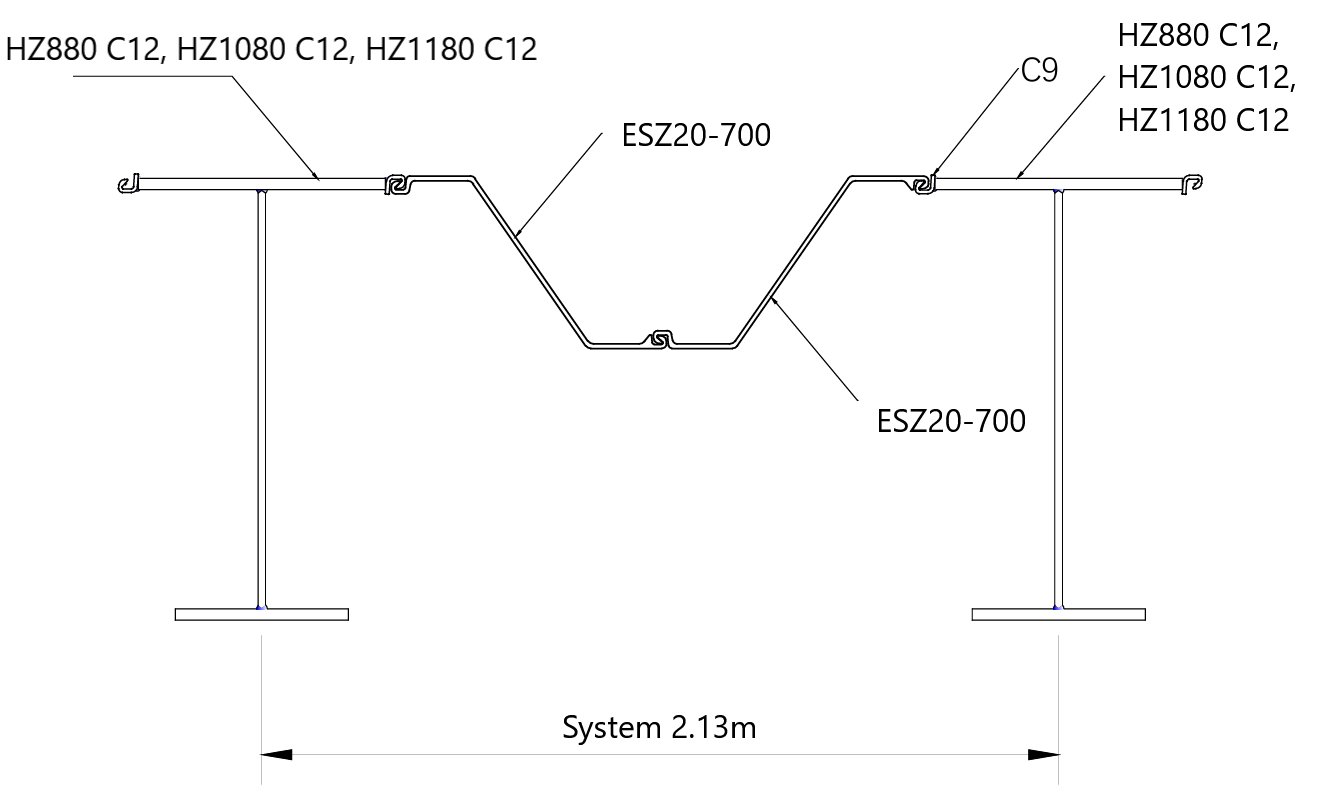

Welded H Piles

Our welded steel H piles—also referred to as structural H beams or bearing piles—are engineered for demanding applications such as retaining walls, deep foundations, port constructions, and marine structures. Unlike standard hot-rolled sections, our tailor-made H beams offer superior adaptability with custom dimensions, optimised profiles, and cost-effective performance.

Typically used to support buildings, bridges, and quay walls, these steel piles ensure long-term stability with high load-bearing capacity. Each H pile is custom-fabricated to meet strict specifications for size, thickness, and load requirements. Whether driven into rock, soil, or sand, our piles ensure stability even under complex ground and surface conditions.

Advantages of Welded H Beams for Retaining Wall:

- Custom Dimensions: Manufactured to match exact project requirements in height, flange width, thickness, and length.

- Better Performance: Custom welded steel beams ensure optimal load-bearing capacity tailored to your needs.

- Cost-Effective Fabrication: Achieve up to 15% CAPEX savings compared to mill rollings or traditional hot-rolled beams.

- Fully Interchangeable: Compatible with standard hot-rolled combi-wall systems and approved by leading EU design bureaus.

- High Structural Integrity: Ideal for retaining wall systems and deep foundation designs.

- Reliable: High weld quality, certified materials, and better performance.

Why Choose Our Welded Steel H Piles?

- Tailor-Made for Your Project: Each H pile is custom-welded to meet specific project requirements — length, width, thickness, and steel grade.

- Superior Structural Performance: Our H piles surpass traditional Hot-rolled beams in sectional area, moment of inertia, and elastic section modulus, resulting in greater strength and improved performance.

- Full Interchangeability with Hot-Rolled: Our welded H piles are fully compatible with industry standards and approved by EU structural design bureaus.

- Fast Production & Logistics: Thanks to flexible manufacturing and strategic partnerships, we can supply volumes quickly and deliver to the site on time.

- Technical Support at Every Step: Our engineering team works closely with you to provide an optimal combiwall or alternative solution, ensuring the best outcomes and economy.

Contact us today to receive a tailored offer for your upcoming project.

Welded H Piles Technical Comparison Table

| Profile | Dimensions (excl. clutches) |

Properties (incl. clutches) |

|||||

|---|---|---|---|---|---|---|---|

| Width Upper Flange (b1) | Width Bottom Flange (b) | Height (h) | Cross sectional Area (A) | Mass | Moment of Inertia (Iy) | Elastic Section Modulus (Wy) | |

| mm | mm | mm | cm² | kg/m | cm⁴/m | cm³/m | |

| Welded HZ880MC sol. 12 |

660 | 460 | 831.3 | 424.88 | 333.53 | 535807 | 10957 |

| Welded HZ1080MC sol. 12 |

660 | 460 | 1075.3 | 523.15 | 410.67 | 1054053 | 17013 |

| Welded HZ1180MC sol. 14 |

660 | 560 | 1083.4 | 677.67 | 531.97 | 1440796 | 24441 |

| Arcelor HZ880MC sol. 12 |

460 | 460 | 831.3 | 384.5 | 301.8 | 477210 | 10725 |

| Arcelor HZ1080MC sol. 12 |

456 | 456 | 1075.3 | 474.8 | 372.8 | 937820 | 16430 |

| Arcelor HZ1180MC sol. 14 |

459 | 459 | 1083.4 | 632.7 | 496.7 | 1331210 | 24385 |

Note: Welded H beam solution surpasses Arcelor’s in all the characteristics and is much better and stronger.

Swipe

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

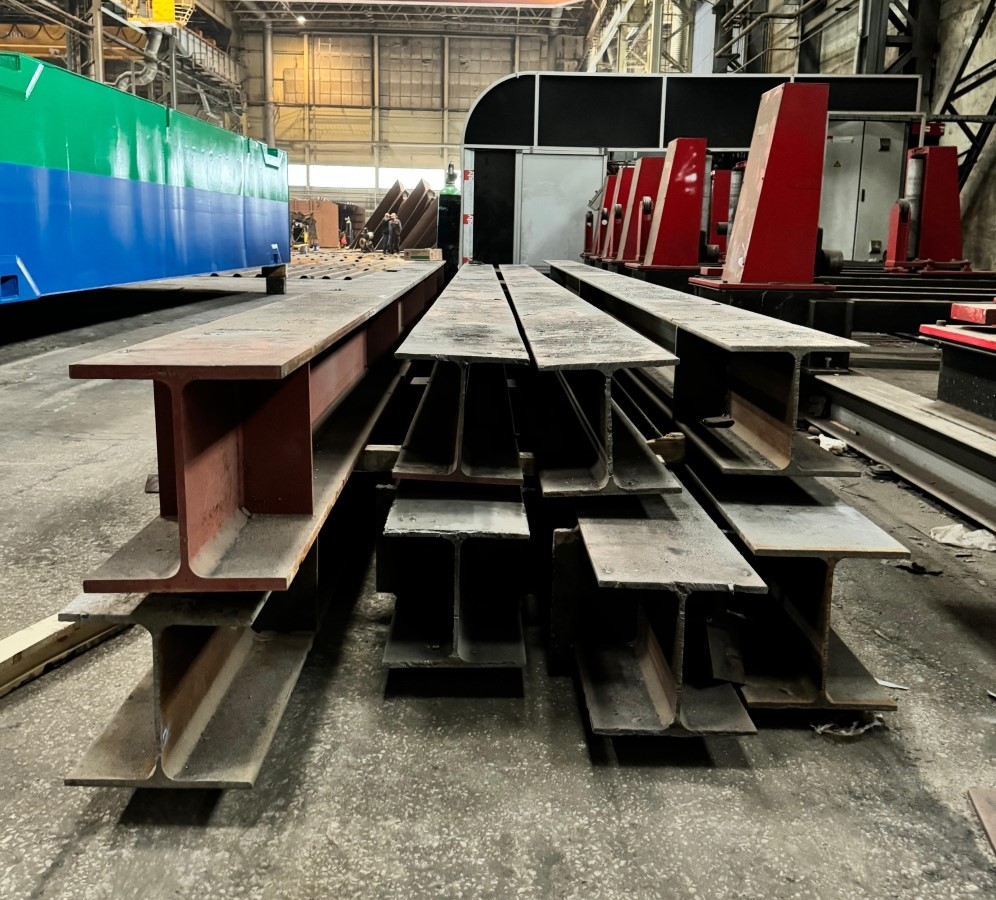

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.