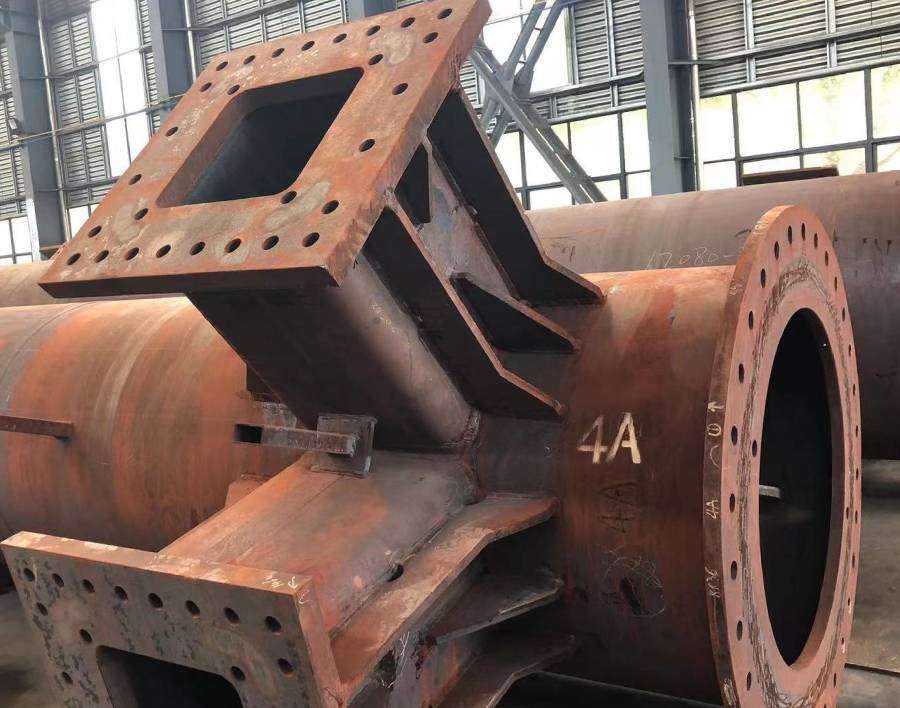

Custom Fabrication of Metal Structures

As a professional importer, Aema Steel specialises in delivering customised metal structures and steel structures for maritime, offshore, energy, and infrastructure projects.

We bridge the gap between suppliers and customers while facilitating international trade. Through long-term partnerships and consortiums, we ensure that our clients receive the most reliable and cost-effective solutions

With a strong supply chain and deep technical knowledge, our solutions are built efficiently and cost-effectively to your original design, ensuring durability in marine environments and beyond.

Customised Steel Solutions for Complex Projects

Our expertise covers a wide range of customised steel applications, including:

- Drilling Platforms: large permanent structures used in offshore drilling operations, include components such as decks, living quarters and support structures.

- Roll-on/roll-off (Ro-ro) Ramps: steel structures used for facilitating the loading/unloading of roll-on and roll-off vessels or ports.

- Headstocks: supporting metal structures for machinery or large equipment installations.

- Pontoons: steel structures for stability and support of floating bridges, docks, or platforms on water.

- Mooring Dolphins: steel structures consisting of piles for guiding ships during mooring or docking.

- Gangways: steel structures used as a walkway or bridge between the ship and the shore.

- Subsea Structures: steel structures for underwater installations, used for supporting purposes.

- Bailey Bridges: These modular bridges are lightweight, high-strength metal structures developed for rapid assembly and installation in challenging environments.

Our Capabilities – From Design to Completion

At Aema Steel, we provide end-to-end support for your metal structure needs—from concept to on-site delivery. Our expertise spans custom structural design, procurement, logistics coordination, and large-module assembly, ensuring a seamless process tailored to your project’s unique demands.

We deliver high-quality structural steel fabrication for a wide range of international applications, including:

- Offshore Steel Structures

- Piling: Pipe Piles, Welded H beams, Sheet Piles.

- Mining and Excavation Structures

- Heavy Steel Fabrication

- Steel Towers

- Material Handling Structures (e.g., conveyors, silos, bunkers)

- Port and Handling Equipment (e.g., ship-loaders, re-claimers, stackers, cranes)

Custom Fabrication Solutions

- Machining, Cutting and Drilling

- High-Quality Welding Services

- Steel Pipe Production

- Press Brake Forming

- Blasting, Coating and Galvanising

Rigorous Testing and Quality Assurance

Every metal structure we deliver is constructed with durability and long-lasting performance in mind. To ensure this, all components undergo thorough inspection and certified testing procedures designed to meet the most demanding commercial and industrial applications.

- Dimensional Measurement: for precise control and accuracy.

- Tensile, Impact, and Chemical Testing: to ensure strength, durability, and material quality.

- Ultrasonic Testing (UT): to detect internal flaws before they impact performance.

- Magnetic Particle Testing (MT): for locating near-surface defects.

- Radiographic Testing (RT): for advanced inspection of welds and internal structures.

- Penetrant Testing (PT): to identify surface-breaking flaws.

- Visual Testing (VT): for detailed visual inspection and structural consistency.

- Coating Inspection: to assess layer thickness, zinc coverage, and corrosion-resistant properties.

- Assembly Load Testing and Pressure Testing: to simulate real-world conditions and validate performance under stress.

Project Management and Technical Support

From the original design concept to completion, our experienced engineers and designers provide hands-on support at every stage. With expertise in hydrotechnics, offshore energy, and civil engineering, we help customers assemble metal structures tailored for performance, speed, and durability.

- Compliance engineering calculations

- 2D and 3D CAD drafting

- Finite Element Analysis

- 3D visualisation and animation

We value our clients’ success as our own and aim to be more than a supplier — we strive to be your trusted partner in creating reliable, efficient, and future-ready solutions.