Offshore Wind Foundations

Engineering Reliable Support for Offshore Wind Turbines

As a trusted supplier and professional importer, Aema Steel specialises in delivering high-quality structural pipe solutions and offshore wind foundation systems engineered for the stability and long-term performance of offshore wind turbines.

Our expertise covers a full range of foundation types, carefully selected based on turbine loads, water depths, and site-specific soil conditions.

We offer a comprehensive range of products, including monopiles, jacket components, pin piles, and other structural parts, all designed to support the construction of utility-scale offshore wind farms. Whether you require cost-efficient, technically proven solutions or expert engineering support, Aema Steel is committed to delivering on every front.

Comprehensive Solutions for Offshore Wind Foundations

01

Monopiles: Strong Foundations for Offshore Wind Turbines

Monopiles are the most prevalent foundation type in the offshore wind industry, particularly suitable for shallow to moderate water depths. These large-diameter steel piles are driven into the seabed using large hydraulic hammers, providing a cost-effective and straightforward solution for many offshore wind projects.

- Outer Diameter: Up to 12 meters

- Piece Weight: Up to 2,500 tons

- Total Length: Up to 120 meters

- Steel Grades: S355, S460, and above

Our engineering expertise and partners’ extensive manufacturing capabilities allow us to meet the large-scale demands of offshore projects with ease, helping developers install wind turbines efficiently. By considering seabed preparation, bearing capacity, and advanced pile installation techniques such as driving or vibratory methods, we help clients achieve optimal results in monopile foundation design and execution.

Jacket Foundations and Components: Stability in Deeper Waters

Jacket foundations are essential for offshore wind farms in deeper waters. These multi-legged structures provide a stable base that supports the wind turbine tower above, especially suitable for larger turbines and challenging site conditions. Jacket Foundation structures are anchored to the seabed using pin piles or, in some cases, suction buckets.

- Outer Diameter: 0.4 – 5.5 meters

- Total Length: Up to 120 meters

- Wall Thickness: Up to 300 mm

- Total Weight: Up to 800 tons per component

At Aema Steel, we offer both jacket foundations and individual jacket components, leveraging our extensive industry expertise. Our team ensures that every pipe and fitting is fabricated for optimal performance and reliability in offshore conditions.

02

03

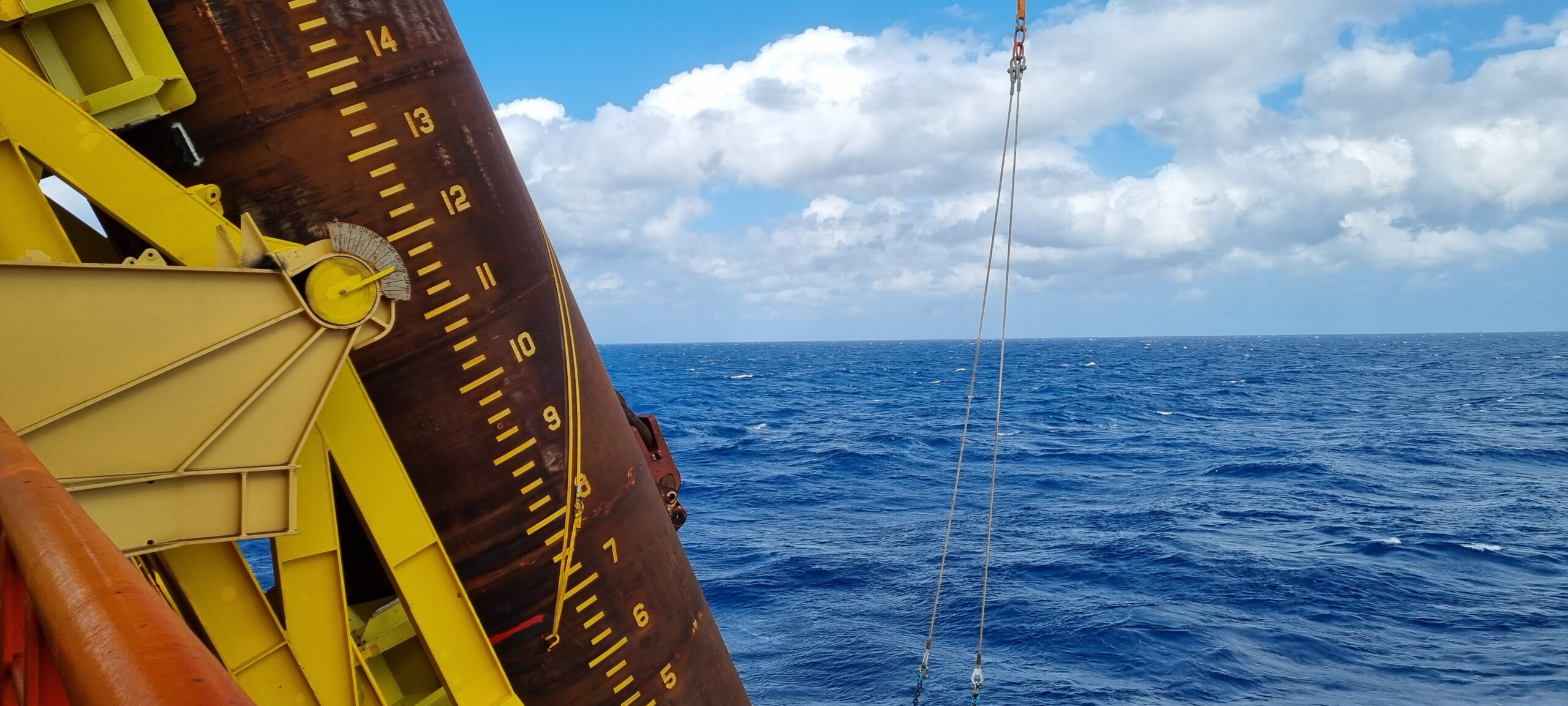

Pin Piles: Securing Offshore Foundations

Pin piles anchor jacket foundations to the seabed, playing a crucial role in the structural integrity of offshore wind farms. They are designed to withstand various environmental conditions, including currents and seabed variations, ensuring proper seabed preparation and final positioning.

- Outer Diameter: Up to 5.5 meters

- Piece Weight: Up to 600 tons

- Total Length: Up to 120 meters

Aema Steel provides pin piles ready for installation, complete with weld beads and level markings to facilitate easier offshore assembly. Our pin piles are designed for fast deployment, helping to streamline the construction process.

Transition Pieces: Connecting Monopiles and Wind Turbine Towers

Transition pieces are used to connect the wind turbine tower with the monopile foundation, ensuring proper alignment and load transfer. Manufactured from high-grade structural steel, they are equipped with essential secondary elements, including access platforms, ladders, internal cabling support, and boat landing systems, which are crucial for the operation and maintenance of the wind turbine.

- Primary Steel Construction: High-grade steel

- Secondary Elements: Platforms, ladders, and boat landing systems

By partnering with Aema Steel, you can rely on a complete package of primary and secondary steel elements, ensuring smooth installation and reduced project complexity.

04

05

Floating Wind Foundations: Pioneering Offshore Energy Solutions

Floating offshore wind foundations are a cutting-edge solution for developing wind farms in deep waters, where traditional gravity-based foundations, or fixed-bottom structures, and monopiles are not feasible. Over the last few decades, floating systems have emerged as a viable support structure, allowing for the installation of wind turbines further offshore, where wind conditions are stronger and more consistent, resulting in a greater and more stable energy yield.

At Aema Steel, we supply a range of high-quality steel structures designed to anchor floating wind towers securely to the seabed. These structures ensure stability in harsh marine environments, allowing the turbines to withstand rough sea conditions and remain operational. Our solutions include components for various floating platforms, such as semi-submersibles, spar buoys, and tension leg platforms. We offer customisable designs to meet project-specific requirements, ensuring efficiency and reliability in even the most challenging deep-water locations.

Floating wind technology represents the future of offshore wind energy, and Aema Steel is at the forefront of providing robust and scalable solutions to support this growing sector.

Engineering & Logistics Support: Complete, High-Quality Solutions

At Aema Steel, delivering top-tier structural components is only the beginning. We provide comprehensive engineering support to ensure each support structure is tailored to your project’s technical and environmental requirements. From the early stages of design to execution, our experienced team works closely with clients to guarantee that every component meets the highest standards and performs reliably in its intended environment.

Additionally, our logistics support ensures that your products are delivered safely, on time, and in perfect condition, regardless of the project’s location. Whether it’s a large-scale wind farm or a smaller offshore installation, Aema Steel is ready to lead your supply chain with precision, performance, and professionalism—every step of the way.

06

Durability and strength for every project, every time

High-Quality Structural Steel Solutions for Every Project