Steel Pipe Piles

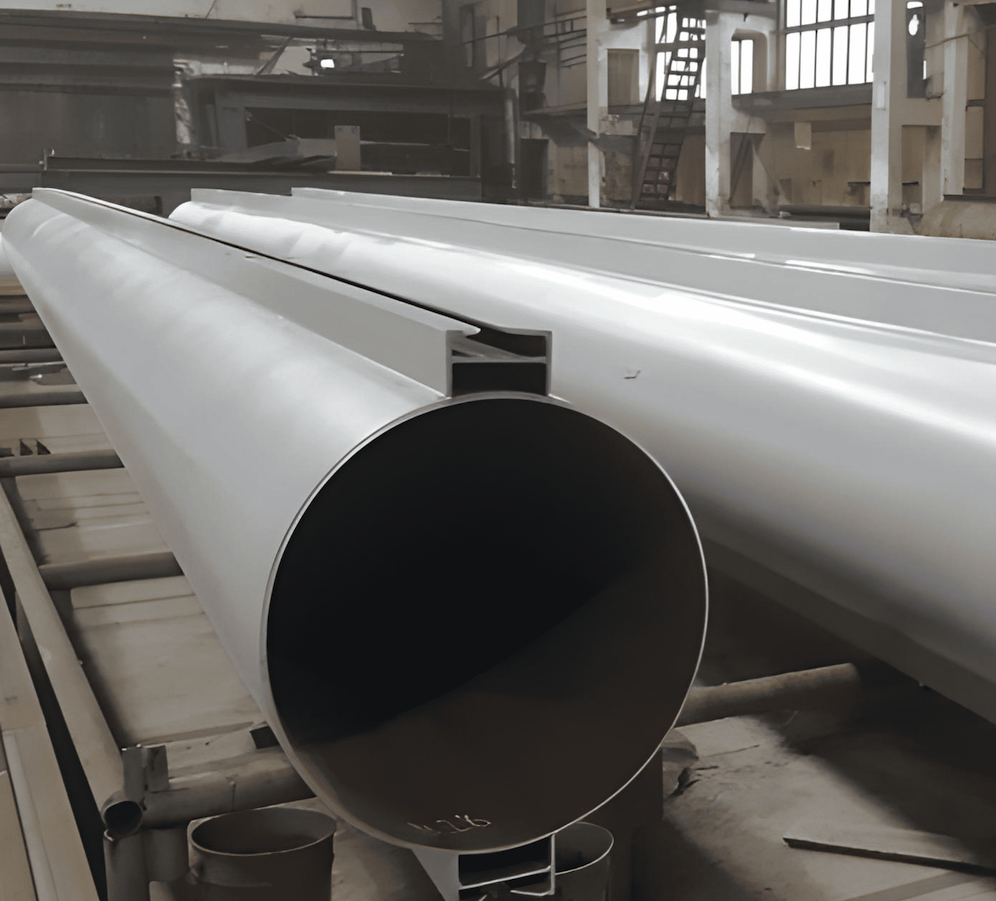

Steel pipe piles consist of steel pipes with welded paired interlocks, typically positioned opposite each other for seamless assembly. These interlocks allow efficient and quick assembly of a continuous wall from individual elements, making them a reliable solution for deep foundations and retaining wall construction.

Steel pipe piles are commonly driven in sequence to form a continuous barrier. They provide high resistance to bending and vertical loads while allowing customisation through various interlock types, wall thicknesses, steel grades, and diameters – ensuring tailored structural solutions for diverse project requirements.

The anti-corrosion treatments extend the lifespan of steel pipe piles, ensuring long-term durability in harsh environments.

Advantages of Pipe Piles:

- Exceptional Structural Stability: Pipe piles are exceptionally resistant to transverse and longitudinal bending, as well as vertical loads, and they are equally rigid in all directions of the cross-section.

- Optimised Strength-to-Weight Ratio: Compared to U-type and Z-type sheet piles, pipe piles provide the highest moment of resistance per linear metre relative to their weight.

- Customisable Strength Properties: The strength properties can be easily scaled within the required limits and costs optimised by adjusting the wall thickness, steel grade, and pipe diameter.

- Corrosion Resistance and Long Service Life: Designed for durability, pipe piles offer long service life even in harsh environments, making pipe piles a cost-effective option.

- Enhanced Reinforcement Options: Pipe piles can be reinforced with additional structural components or concrete filling to improve load-bearing capacity and durability.

- Versatile Installation: The pipe pile wall installation does not require extensive excavation and can be installed in various soil conditions.

Terms of Supply and Payment Schedule

Considering the manufacturing and delivery times from our exclusive global partners, which might take as long as 30 – 90 days, we offer flexible payment terms including:

- A minimal advance payment for order confirmation.

- Flexibility to pay after the products are delivered to your warehouse or construction site.

- Up to 90 days of installment plans or deferred payments are available.

Our Supply Capabilities

Custom Sizes and Flexibility:

- We can supply diverse pipe piles range of any length, wall thickness, and diameter to meet the specific needs of your project.

- We analyse project specifications to determine the optimal wall thickness and pipe type to reduce steel weight and material costs.

Compliance with International Standards:

- Our supplied products meet international quality standards.

- Upon request, we can provide spiral-welded or longitudinally welded seam pipes tailored to your requirements.

Welded Clutches and Custom Solutions:

- We can weld any type of clutches required for your project.

- Anti-corrosion treatment and various coating options are available upon request.

Unlimited Size Range:

- We are not limited to standard specifications and offer complete flexibility of supplying custom sizes for your specific tasks.

Tailored Solutions for Your Needs:

- Our key advantage is the ability to manufacture according to customer specifications, ensuring an ideal fit for your project’s requirements.

- In addition to pipe piles, our production capabilities include welding, allowing us to create various pipe structures and weld additional elements upon request.

Available Pipe Types and Dimensions

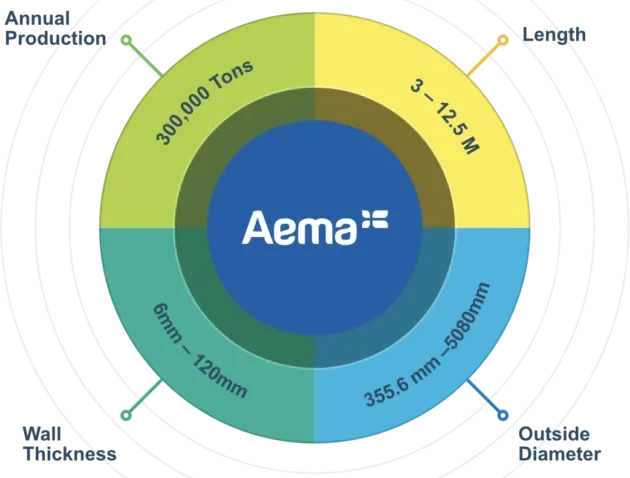

Steel Pipes LSAW

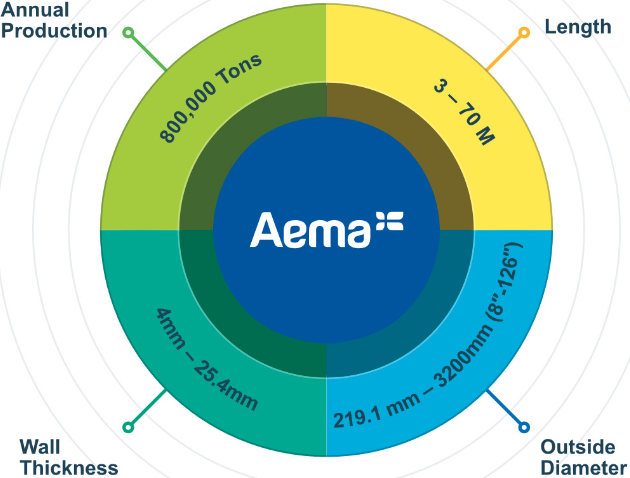

Steel Pipes SSAW

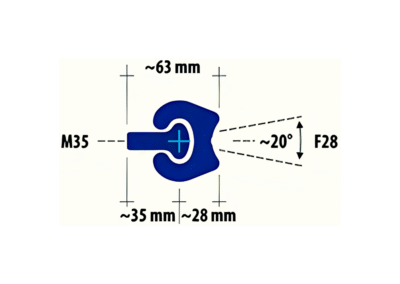

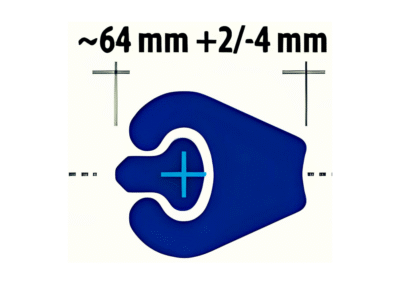

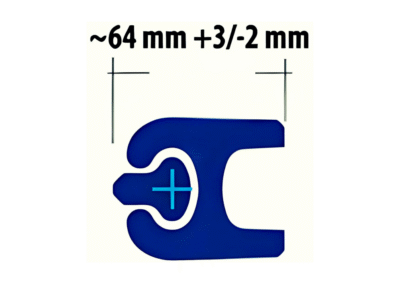

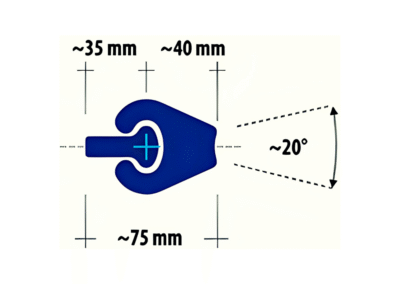

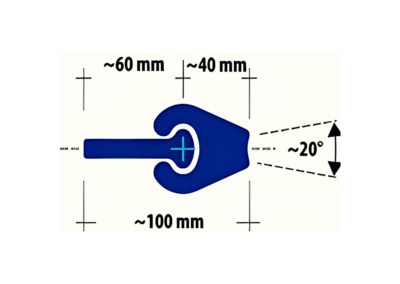

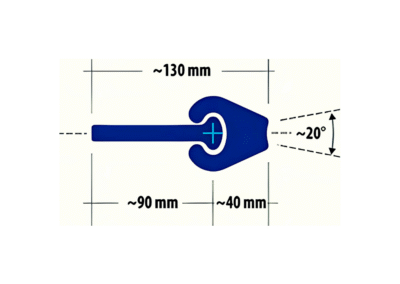

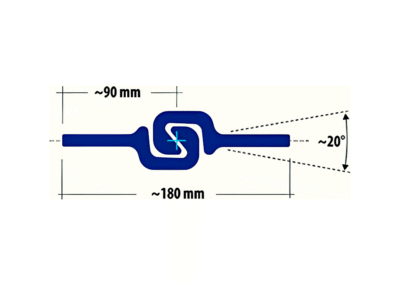

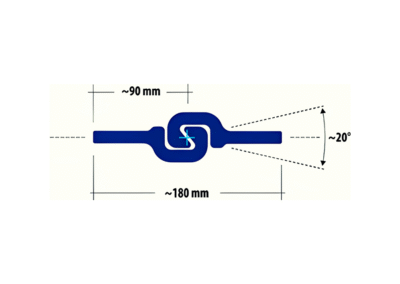

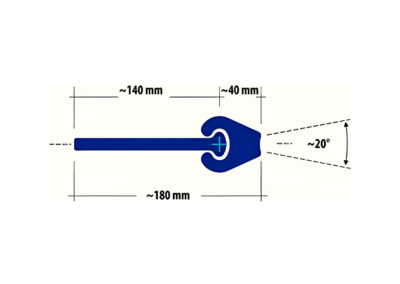

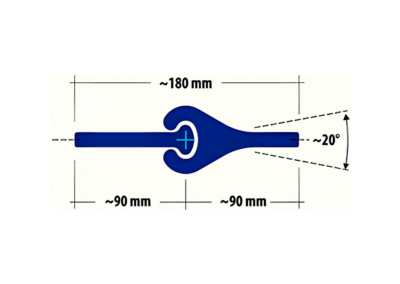

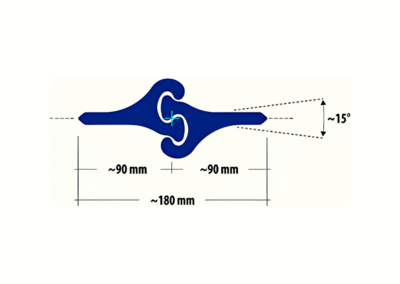

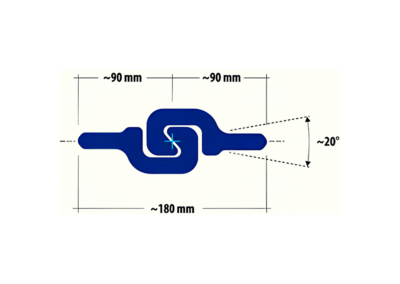

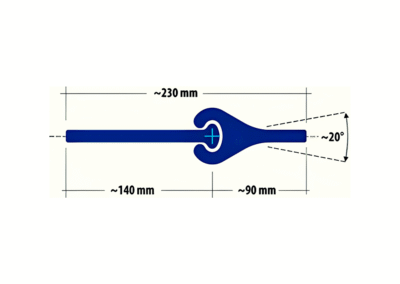

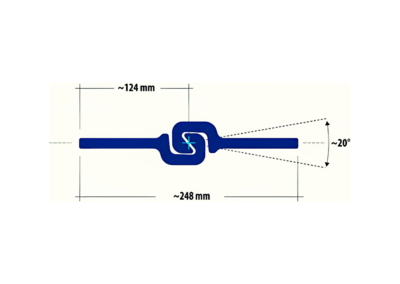

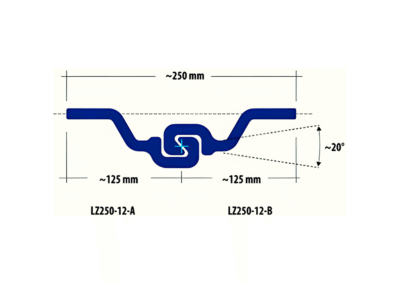

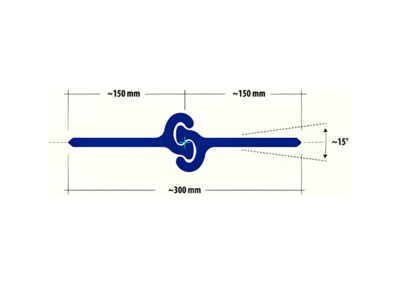

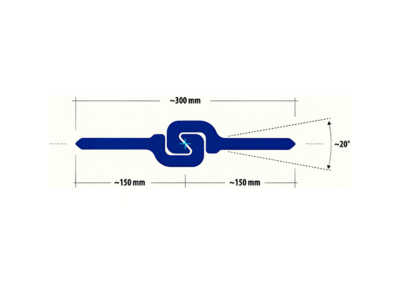

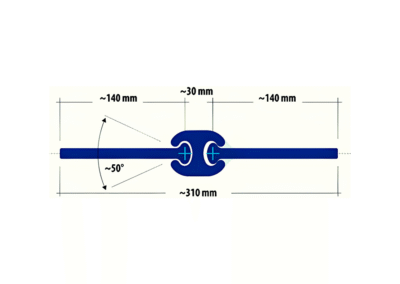

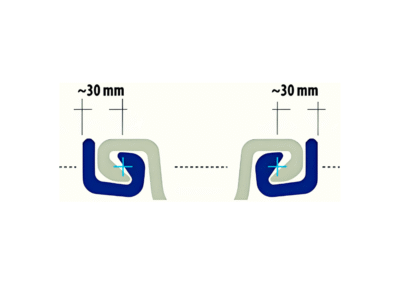

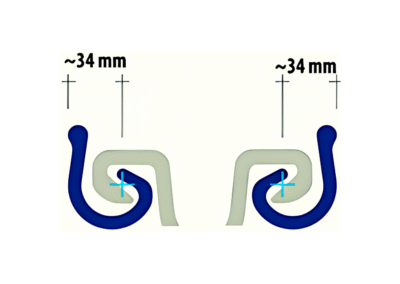

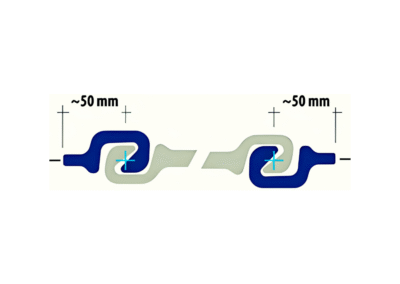

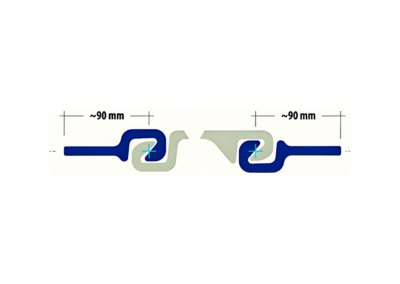

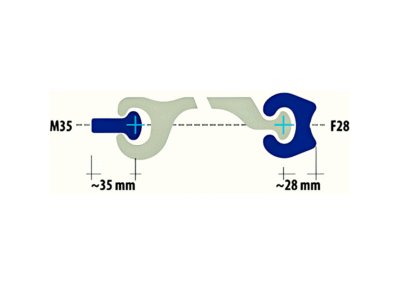

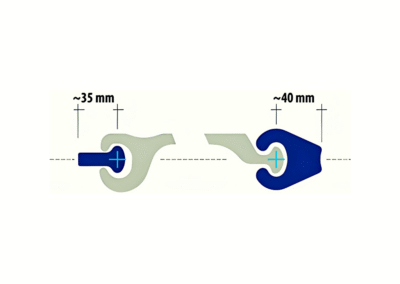

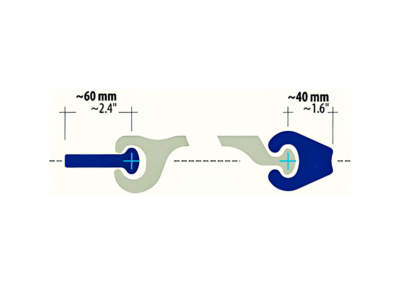

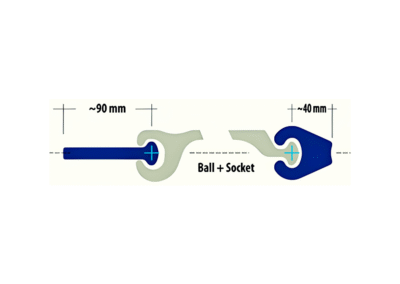

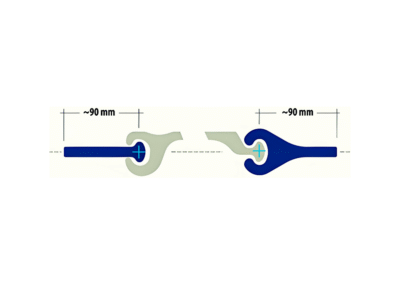

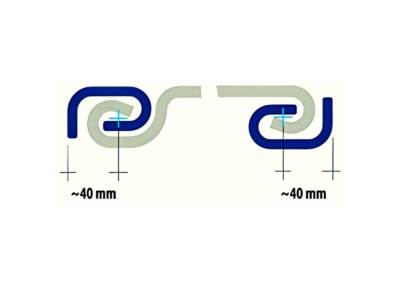

Clutches Diagrams

Specifications

Clutches for Pipe Pile Steel Walls

| Name | Steel grade | Steel thickness (mm) | Standard length (m) | Weight (kg/m) | Max. tensile strength (kN/m) |

|---|---|---|---|---|---|

| MF 63 | S355 | 12 | 8, 11.8 | M35: 4.76 F28: 10.7 |

2552 |

| MF 64 | S355 | 12 | 8, 11.8 | M22: 3.42 F40: 14.28 |

3419 |

| MF64-IC | S355 | 10, 12 | 8, 11.8 | M22: 3.42 F40-IC: 13.55 |

3164 |

| MF75 | S355 | 12 | 8, 11.8 | M35: 4.76 F40: 14.28 |

3419 |

| MF100 | S355 | 12 | 8, 11.8 | M60: 6.9 F40: 14.28 |

3419 |

| LPB100-10 | S355 | 10 | 8, 11.8 | 9.9 | |

| MF130 | S355 | 12 | 8, 11.8 | M90: 9.76 F40: 14.28 |

3199 |

| LPB180-10 | S355, S430 | 10 | 8, 11.8 | 12.84 | |

| LPB180-12 | S355 | 12 | 8, 11.8 | 14.5 | 1502 |

| MF180a | S355 | 12 | 8, 11.8 | M140: 14.7 F40: 14.28 |

3419 |

| MF180b | S355 | 12 | 8, 11.8 | M90: 9.76 F90: 18.42 |

2128 |

| FD180 | S355 | 12 | 8, 11.8 | 17.42 | 5843 |

| LPB180-12 | S355 | 12 | 8, 11.8 | 22.4 | 1828 |

| MF230 | S355 | 12 | 8, 11.8 | M140: 14.77 F90: 18.42 |

2128 |

| LPB248-12 | S355 | 12 | 8, 11.8 | 18.26 | 1500 |

| LZ250-12 | S355 | 12 | 8, 11.8 | 19.48 | 1200 |

| FD300-12 | S355 | 12 | 13.8 | 21.4 | 6312 |

| LPB300-16 | S355 | 16 | 8, 11.8 | 29.65 | 1828 |

| MDF310 | M: S355 DF: S430 |

12 | 8, 11.8 | M140: 14.77 DF: 14.62 |

3271 |

Pipe Pile Combined Steel Walls

| Name | Steel grade | Steel thickness (mm) | Standard length (m) | Weight (kg/m) | Max. tensile strength (kN/m) |

|---|---|---|---|---|---|

| L8/E22 | S355 | 9.5 | 11.8 | 8.47 | |

| LV22 | S355 | 8 | 11.8 | 8.02 | |

| LPB100-9A | S355 | 9 | 8, 11.8 | 9.05 | 912 |

| LPB180-10 | S355, S430 | 10 | 8, 11.8 | 12.84 | |

| MF 63 Ball & Socket Sheet Piles Z | S355 | 12 | 8, 11.8 | M35: 4.76 F28: 10.7 |

2552 |

| MF75 Ball & Socket Sheet Piles Z | S355 | 12 | 8, 11.8 | M35: 4.76 F40: 14.28 |

3419 |

| MF100 Ball & Socket Sheet Piles Z | S355 | 12 | 8, 11.8 | M60: 6.9 F40: 14.28 |

3419 |

| MF130 Ball & Socket Sheet Piles Z | S355 | 12 | 8, 11.8 | M90: 9.76 F40: 14.28 |

3199 |

| MF180b Ball & Socket Sheet Piles Z | S355 | 12 | 8, 11.8 | M90: 9.76 F90: 18.42 |

2128 |

| MDF310 Ball & Socket Sheet Piles Z | M: S355 DF: S430 |

12 | 8, 11.8 | M140: 14.77 DF: 14.62 |

3271 |

| CF-Junction for Cold Rolled Sheet Piles | S355 | 8 | 11.8 | 8.87 |

Swipe

Note: The above specification is only a part of all the sizes, more sizes are available to suit specific project needs. Contact us for detailed information and customised solutions

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.