Post Tension Concrete Technology

Reduce construction costs by up to 20%

What is Post-Tensioning?

Post tension concrete or Post-tensioning is a method of prestressing concrete where the tendons (steel strands) are tensioned after the concrete has been cast and has gained sufficient strength. The tension is applied using hydraulic jacks to compress the concrete, improving its performance under service loads.

Prestressing steel strands are placed inside plastic ducts within the formwork before the concrete is poured. Once the concrete has hardened, but before permanent loads are applied, the tendons are tensioned and anchored at the edges of the structure.

Post-tensioning systems are engineered to improve the performance of concrete slabs, concrete beams, columns and other structural elements by introducing compressive stress after the concrete has hardened. This method is widely used in both in situ construction and pre-manufactured components.

Key Benefits of Post Tension Concrete

Increased usable and sellable area

Post-tensioning allows for longer spans and fewer columns, resulting in a more open and sellable floor area.

Crack-Free Structures

Eliminates cracks caused by bending, shrinkage, and ground movements, enhancing durability and appearance.

Improved load-bearing capacity

Improves structural strength and extends the service life of structures.

Efficient Stress Distribution

Distributes stress more evenly across the entire structure, improving performance and reducing fatigue.

Material and Cost Savings

Post-tensioning allows for thinner slabs and reduced rebar usage, lowering total material consumption and minimising loads transferred to foundations.

Faster Construction Timelines

Post-tensioning accelerates the construction process by reducing formwork time and allowing earlier loading and use of the structure.

Our Services

- Consulting: Expert guidance on project feasibility and system suitability.

- Feasibility Analysis: In-depth economic and structural analysis for post-tensioning implementation.

- Design Engineering: Custom structural designs tailored to post-tensioning technology.

- System Supply: Professional on-site installation of post-tensioning systems.

- Installation: for advanced inspection of welds and internal structures.

- Concrete Works: Full-service concrete pouring integrated with post-tensioning applications.

Each service is available as part of a complete package or as a standalone offer, depending on your project needs.

Post Tension Concrete Application Areas

Post-tensioning technology is ideal for a wide range of demanding structural projects, including:

- Stadiums, arenas, and sports facilities

- Multi-level and underground parking structures

- High-rise buildings and towers

- Residential construction, commercial and industrial buildings

- Industrial flooring systems

- Bridges, ports, and waterfronts

- Reinforced concrete storage tanks

- Dams, spillways and navigation locks

Rebar Couplers

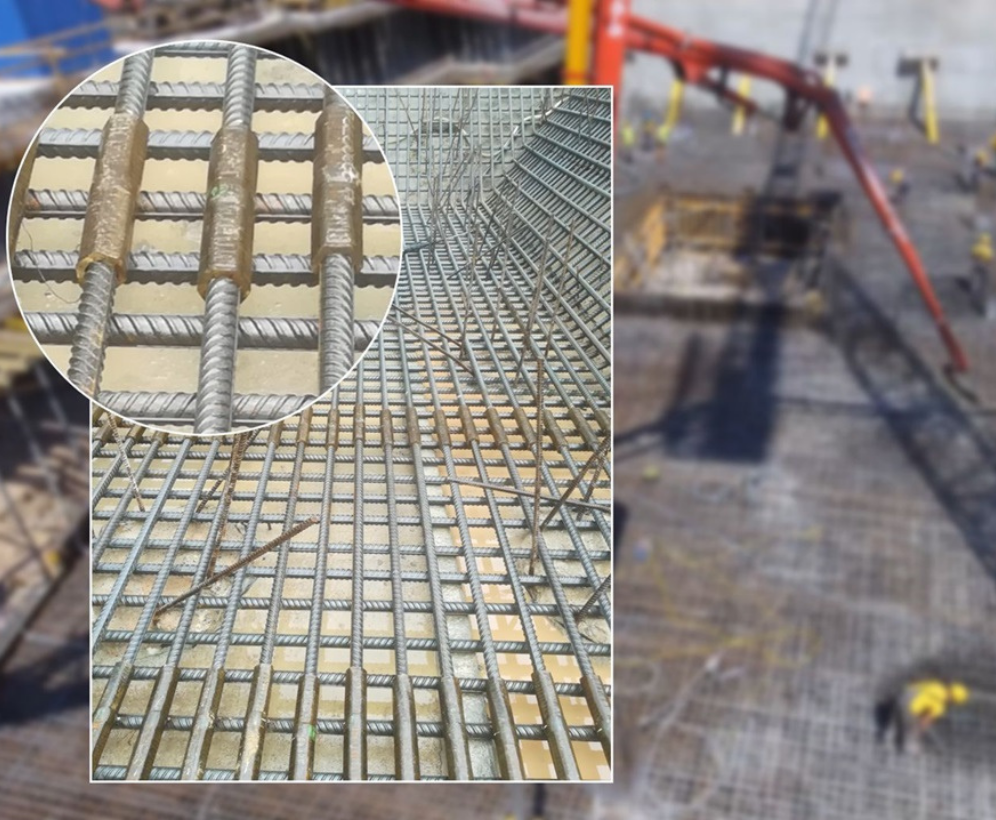

Mechanical couplers offer a reliable and compact solution for rebar splicing in reinforced concrete structures. Rebar couplers improve overall strength and simplify reinforcement layout without the need for overlapping bars.

- Secure and space-saving connection of rebar ends.

- Enhanced structural strength and seismic resistance.

- Efficient in tight construction areas, reducing labour intensity.

- Enable the use of short or leftover bar lengths, minimising material waste.

- Ideal for high-load, seismic, and prefabricated applications.

We supply a full range of rebar couplers that meet international standards for mechanical splicing.

Achieve up to 20% savings on total rebar quantities and labour costs with an optimised coupler solution.

Void Formers

Void formers are engineered to reduce the volume of concrete in slabs without compromising the concrete’s strength. By creating internal cavities, they allow for lighter structures and increased material efficiency.

Advantages:

- Reduction of concrete volume and dead weight of slabs.

- Decreased load on foundations.

- Improved energy efficiency of the building due to optimised thermal mass.

- Ideal for large-span slabs in commercial and residential buildings.

We provide spherical void formers suitable for cast-in-place and precast concrete systems.

Save up to 30% on concrete and rebar quantities without sacrificing quality or structural performance.