Introduction: Why Steel H Beam Dimensions Matter

In deep foundation engineering, the choice of steel H beam dimensions directly influences how well a foundation transfers loads into the ground and adapts to soil conditions. Hot-rolled H beams are produced in a fixed range of commonly used standard dimensions and specifications, making them readily available and reliable for many foundation works. However, when projects require non-standard solutions, welded H beams can be fully customised. They can be fabricated with greater width or thickness for higher stiffness, or balanced in plate sizes to achieve the required performance while optimising weight and cost. This flexibility ensures that engineers and contractors can tailor each pile to meet the specific technical and economic demands of modern foundation projects.

Section Properties of Steel H Piles

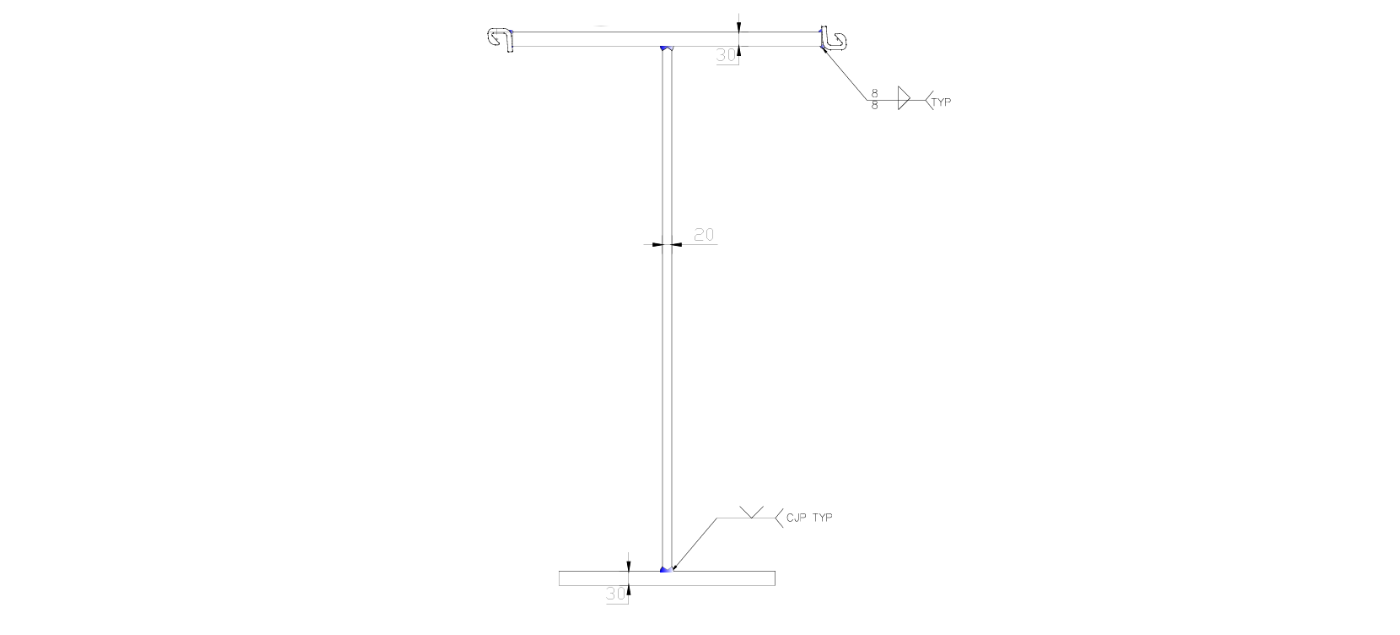

Steel H piles, often referred to as H beams or H sections, are valued in the construction industry for their exceptional strength, drivability and versatility. The section properties of these steel beams, such as area, moment of inertia, and section modulus, are fundamental to their performance in supporting heavy loads and resisting bending or deformation.

For structural engineers, understanding these properties is essential when selecting the right type and size of H beam for a given project. The cross section of an H beam, with its wide flanges and robust web, provides a high moment of inertia, making it ideal for applications where both vertical and lateral loads are significant. This shape allows H sections to distribute forces efficiently, minimising deflection and maximising stability in foundations and other structures.

Standard vs. Custom Dimensions

Hot-rolled H piles are produced in a fixed range of standardised dimensions under recognised specifications, giving engineers predictable section properties for design. Their availability makes them a reliable option for many foundation works, but they are manufactured by a limited number of mills, which can constrain supply and lead to longer procurement times.

By contrast, welded H piles can be fabricated in customisable dimensions from plate material, offering greater flexibility. They can be made wider, deeper, or with optimised plate thicknesses to achieve the required performance while balancing weight and cost — often making them the more economical option for large or complex projects.

Why Custom Steel H Pile Dimensions Are Important

- Optimised Load Capacity – Dimensions can be tuned to handle axial, lateral, and bending forces.

- Soil Adaptation – Narrower sections for dense soils, heavier sections for soft ground.

- Cost Efficiency – Using lighter infill sheet piles in combi wall systems while king piles carry the main load.

- Design Freedom – Allows architects and engineers to match piles with non-standard structures.

- Future-Proofing – Custom sizing ensures compliance with stricter environmental and safety codes

Customisation Scenarios in Piling Projects

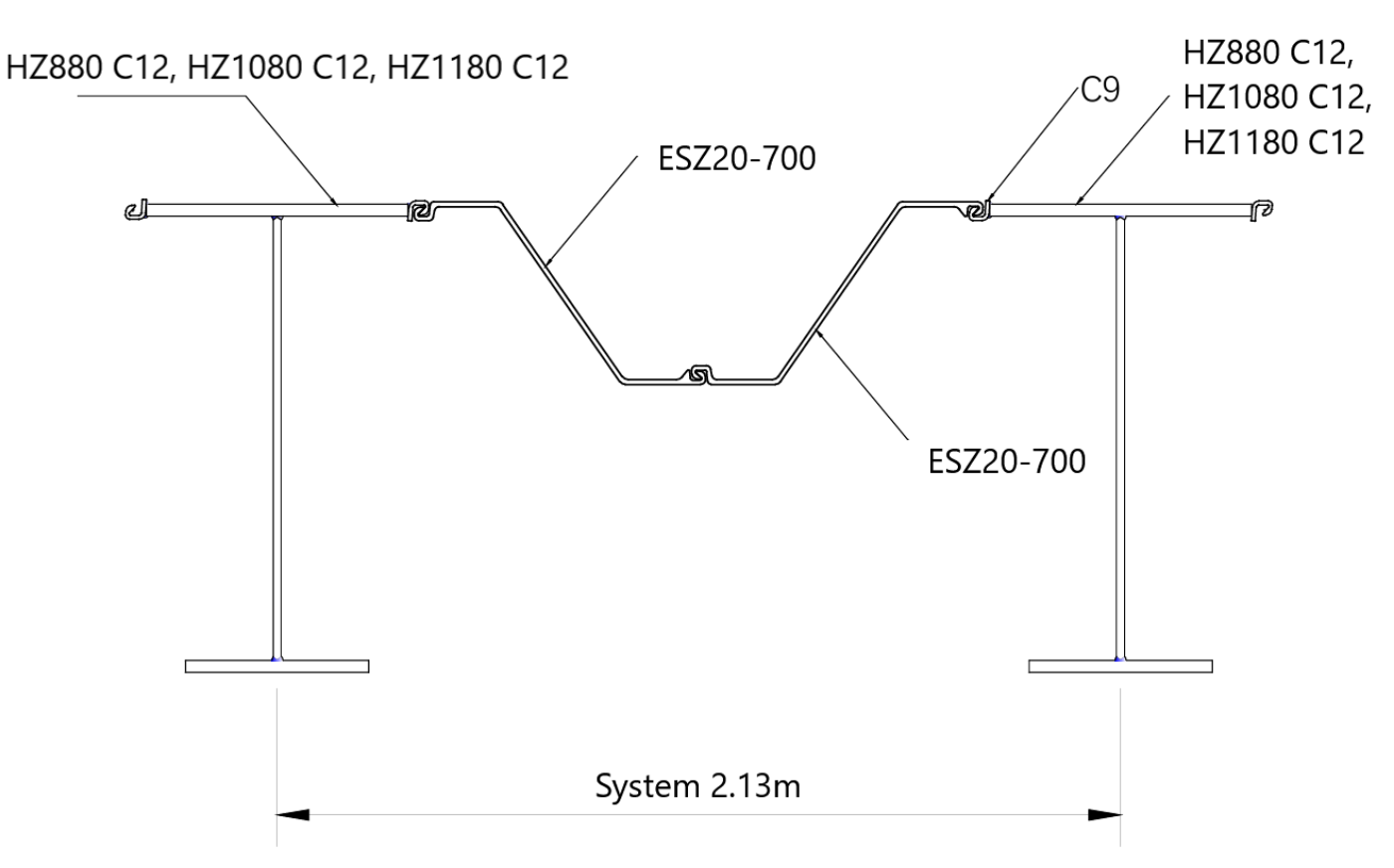

Customisable steel H beam sizes are especially valuable in foundation and combi wall design, where project conditions rarely fit a one-size-fits-all approach. Typical scenarios include:

- Increasing flange width → increase section modulus, enabling wider king pile spacing in combi walls and reducing the total number of piles required.

- Thicker plates → deliver additional stiffness and strength, particularly useful for walls exposed to high surcharges or dynamic marine forces.

- Balanced web and flange thickness → achieves required performance with leaner weight, improving cost efficiency.

- Extended lengths → minimise splicing, simplifying installation in deep foundations.

Applications Where Custom Steel Beam Dimensions Add Value

While standard hot-rolled piles serve many projects, customised welded H piles are particularly advantageous in demanding or non-standard works:

- Ports and Harbours – as king piles in combi walls where wider spacing and higher bending resistance are required.

- Offshore Energy – jacket foundations, substations, and transition structures needing oversized members.

- Bridges and Highways – deep foundations requiring optimised load transfer.

- Flood Protection Works – levees, dikes, and seawalls with high hydrostatic and cyclic loading.

- Industrial Foundations – refineries, heavy machinery, and modular platforms where durability and capacity must be tuned to site-specific loads.

Conclusion

While hot-rolled H piles offer widely available standard sections, welded H piles provide unmatched flexibility in tailoring steel H pile dimensions to exact project needs. For projects where load capacity, soil conditions, or geometry go beyond standard specifications, customisation is the key to safe and cost-effective design.

From ports to offshore wind, bridges to flood protection, the ability to fine-tune dimensions ensures that welded H piles remain at the core of safe, efficient, and future-proof foundation design.

Related Products from Aema Steel

- Welded H Piles

- Steel Tie Rod Systems

- Hot Rolled U Type Sheet Piles

- Hot Rolled Z Type Sheet Piles

- Steel Pipe Piles

Contact us today to receive a tailored offer for your upcoming project.