Introduction: What Are Welded H Beams?

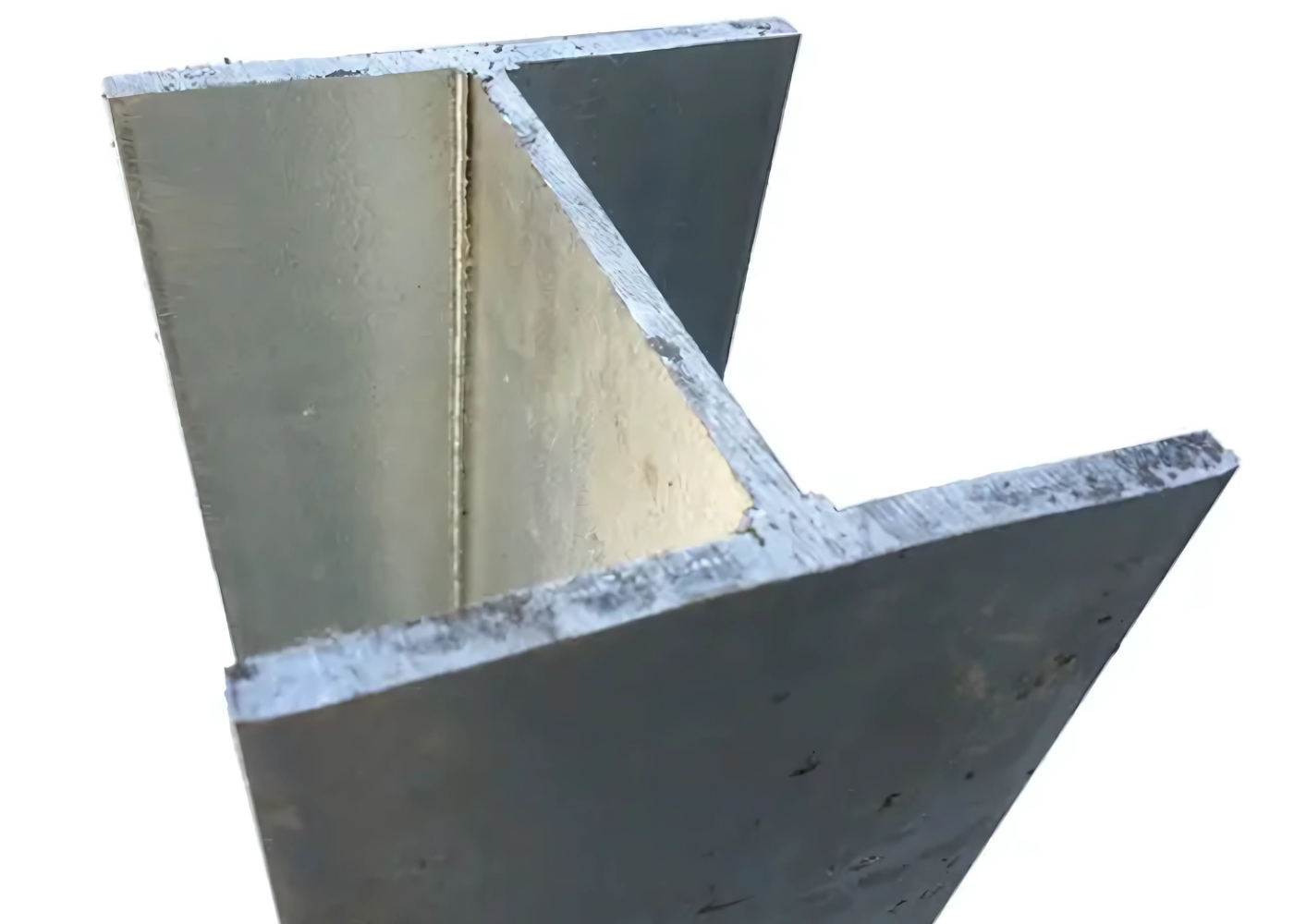

Welded H beams are structural steel components fabricated by welding three individual steel plates: one web and two flanges, to form an H-shaped cross-section. Unlike hot-rolled beams, which are limited to standard sizes, welded H beams can be customised in height, width, and thickness, offering flexibility that hot rolling mills cannot provide.

This adaptability makes welded beams a solid choice for marine and offshore structures, deep foundations, retaining systems, bridges, and heavy industrial frames, where large load-bearing capacity and tailored dimensions are critical.

This guide explores what welded H beams are, how they are produced, why they are preferred in certain applications, and how they compare to other steel beam types.

Key Benefits of Welded H-Shaped Steel Beams

1. Customisable Dimensions

The greatest advantage of welded H beams is their design flexibility. Engineers can specify beam height, flange width, and web and flange thicknesses according to project requirements. This allows the creation of beams with a high load-bearing capacity or fewer raw materials for cost savings. H beam welding provides flexibility beyond what’s available from hot-rolled steel H beams.

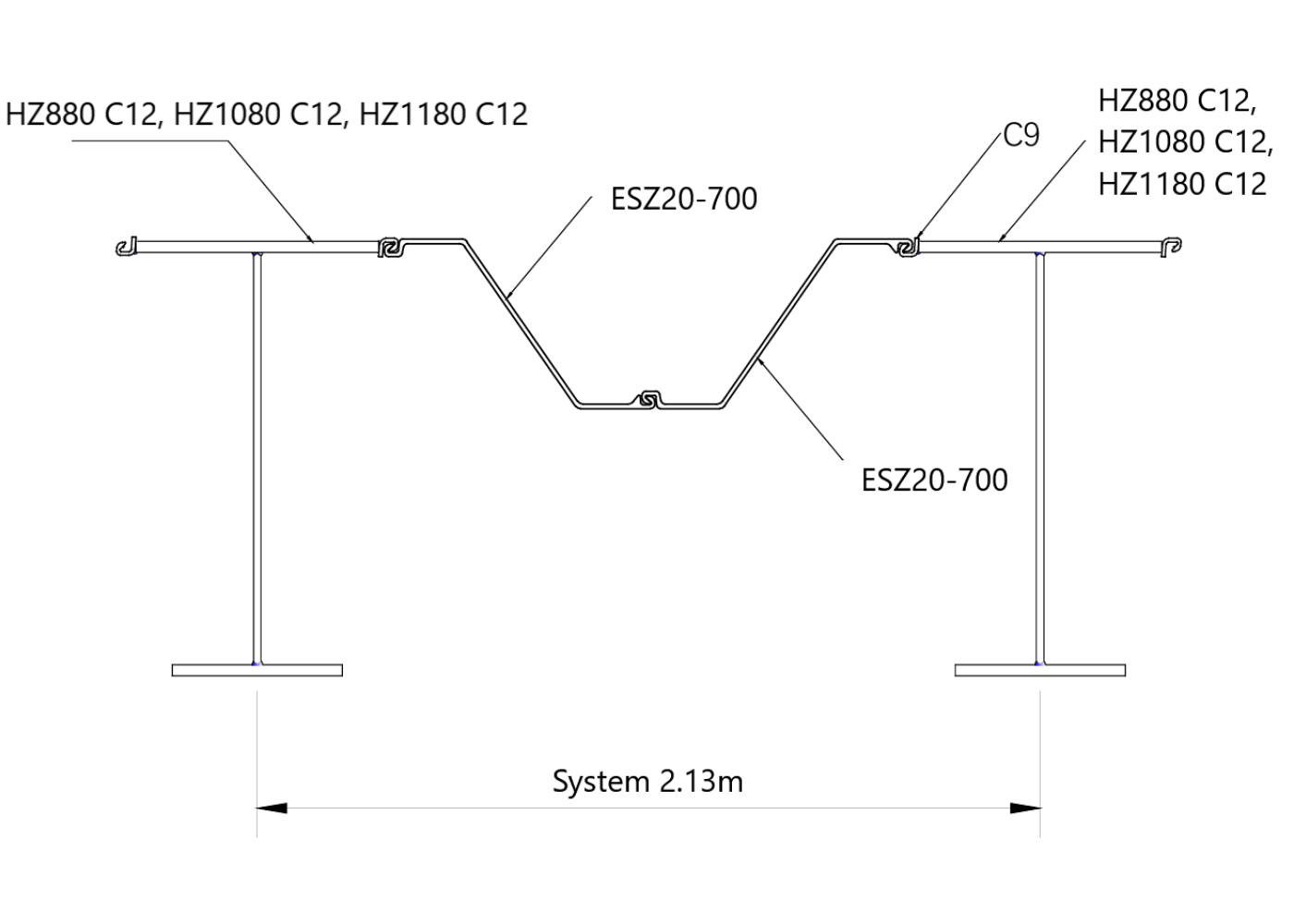

Example: In quay wall combi walls, the upper flange width can be increased to increase the system width, and by adjusting flange and web thicknesses, the beam’s performance can be customised. This makes it possible to match or even outperform hot-rolled sections, often in a more economically efficient way.

2. High Structural Stability and Load-Bearing Capacity

By adjusting plate thickness and widths, welded H beam specifications can be designed to handle significant vertical and lateral loads, making them suitable for demanding projects. Welding allows the production of extra-large beams without requiring specialised rolling mills. This makes welded beams the preferred solution for oversized dimensions.

3. Material Optimisation

Engineers can design H-shaped steel beams specifically for where the stresses occur most, with thicker flanges for bending and slimmer webs for weight reduction, leading to a more efficient and cost-effective structure. This is especially valuable for projects where material use must be optimised due to weight or sustainability considerations.

4. More predictable Lead Times

While fabrication adds time, welded beams avoid the limited rolling schedules of mills, especially for oversized beams. This makes them a practical choice when hot-rolled supply is restricted or when non-standard sizes are required quickly.

Applications of Welded H Beams

Foundation Systems and King Piles in Combi Walls

Welded H beams are commonly used as King Piles in combi wall systems, especially for quay walls and sheet pile retaining structures. Their high bending stiffness and ability to connect with interlocks make them ideal for deep foundation applications.

Offshore and Marine Structures

In offshore jacket foundations, welded H beams are used for:

- Diagonal and vertical bracing in jacket foundations.

- Node connections, skirt piles, and transition pieces.

- Pressure resistance: can withstand cyclic wave and wind loads in harsh marine environments.

Bridge and Infrastructure Works

Custom-welded H beams serve in:

- Bridge girders and viaduct supports where custom spans are required

- Craneway structures and pile caps with high load concentrations

- Suitable for seismic zones due to tailored stiffness-to-weight ratios

Heavy Industry and Equipment Supports

Steel frameworks for:

- Refineries and chemical plants

- Heavy machinery bases requiring point-load capacity

- Pipe racks, modular skids, and industrial platforms

H Beam Welding Process

The fabrication process involves cutting, assembling, and welding H shaped steel structure. Here’s a breakdown:

Manufacturing Process of Welded H Beams

The production of welded H beams involves the following stages:

1. Plate Cutting:

Steel plates from high steel grades are cut to the desired web and flange dimensions using CNC flame or plasma cutting machines.

2. Beveling and Preparation:

The edges are bevelled to prepare for deep penetration welds and minimise welding defects.

3. Assembly and Welding:

Plates are aligned in a jig system to ensure high precision and squareness before welding. The three parts (2 flanges and 1 web) are assembled and tack welded, then joined using submerged arc welding (SAW) or MIG/MAG welding, depending on the specification.

Automatic submerged arc welding (SAW) is the preferred method due to:

- Deep weld penetration

- High deposition rate

- Consistency in weld quality

Weld seams typically run along both flange-web joints.

4. Straightening and Stress Relieving:

Post-welding straightening and optional heat treatment eliminate distortion and reduce residual stress.

5. Drilling and Machining (if required)

Bolt holes, notches, and connection plates are machined as per shop drawings.

6. Surface Treatment

Beams are cleaned (e.g., SA 2.5 grit blasting) and coated with primer or corrosion protection as per project requirements.

7. Marking & Testing

Non-destructive testing (NDT) such as UT, MT, or RT is often performed in accordance with EN 1090-2 EXC3/EXC4 for critical applications.

Fabrication and Welding Standards

Welded H beams are produced according to:

- EN 1090-2 (Execution of steel structures)

- ISO 3834-2 (Welding quality requirements)

- AWS D1.1 or EN ISO 5817 for weld quality

Quality control includes:

- Ultrasonic Testing (UT) of welds

- Dimensional inspections

- Material test certificates (MTCs)

- WPS and WPQR documentation

Why Choose Welded H Beams over Hot-rolled H Beams?

Welded H beams offer the ultimate solution when standard profiles are not enough. Whether you’re designing a bridge in a seismic zone, a quay wall for port expansion, or a complex offshore substation frame, welded beams provide:

- Customisable dimensions for optimised strength and unit weight

- Compliance with stringent engineering requirements

- Compatibility with global project standards

- Resistance to harsh marine and industrial environments

With the ability to design each section to meet unique load requirements, welded H beams offer unmatched performance and value — ensuring your structures are both safe and economically optimised.

Related Products from Aema Steel

- Welded H Piles

- Steel Tie Rod Systems

- Hot Rolled U Type Sheet Piles

- Hot Rolled Z Type Sheet Piles

- Steel Pipe Piles

Contact us today to receive a tailored offer for your upcoming project.