Introduction

As demands on building efficiency and material optimisation increase, engineers and contractors are turning to void formers as a powerful solution to reduce concrete usage, minimise dead loads, and manage soil-related risks. These engineered systems, often made from lightweight materials such as expanded polystyrene (EPS), introduce controlled voids within reinforced concrete slabs and reinforced concrete ground beams.

Void formers are no longer niche components in structural design; they have become essential tools in achieving cost-effective, sustainable, and technically sound construction.

This guide explores everything you need to know about void formers: their purpose, types, benefits, technical requirements, installation, and practical applications in structural and geotechnical projects.

What Are Void Formers?

Void formers are lightweight, prefabricated elements—most often made from expanded polystyrene (EPS)—used to create controlled cavities within or beneath concrete elements. These voids improve efficiency by reducing material use while maintaining structural performance. EPS is widely used due to its low density, formability, moisture resistance, and wide range of compressive strengths.

When cast into reinforced concrete slabs or beams, void formers enable:

- Material efficiency (less concrete and rebar)

- Weight reduction of structural components

- Protection against ground heave and lateral soil pressure

- Thermal insulation and acoustic dampening in specific applications

Types of Void Formers

The selection of a void former system depends on structural demands, soil conditions, and project-specific constraints. Key types include:

Flat Sheet EPS Void Formers

Used mainly under ground beams and floor slabs, flat sheets act as compressible fill to allow for soil movement due to moisture change. They are commonly used in sites with clay soils susceptible to ground heave.

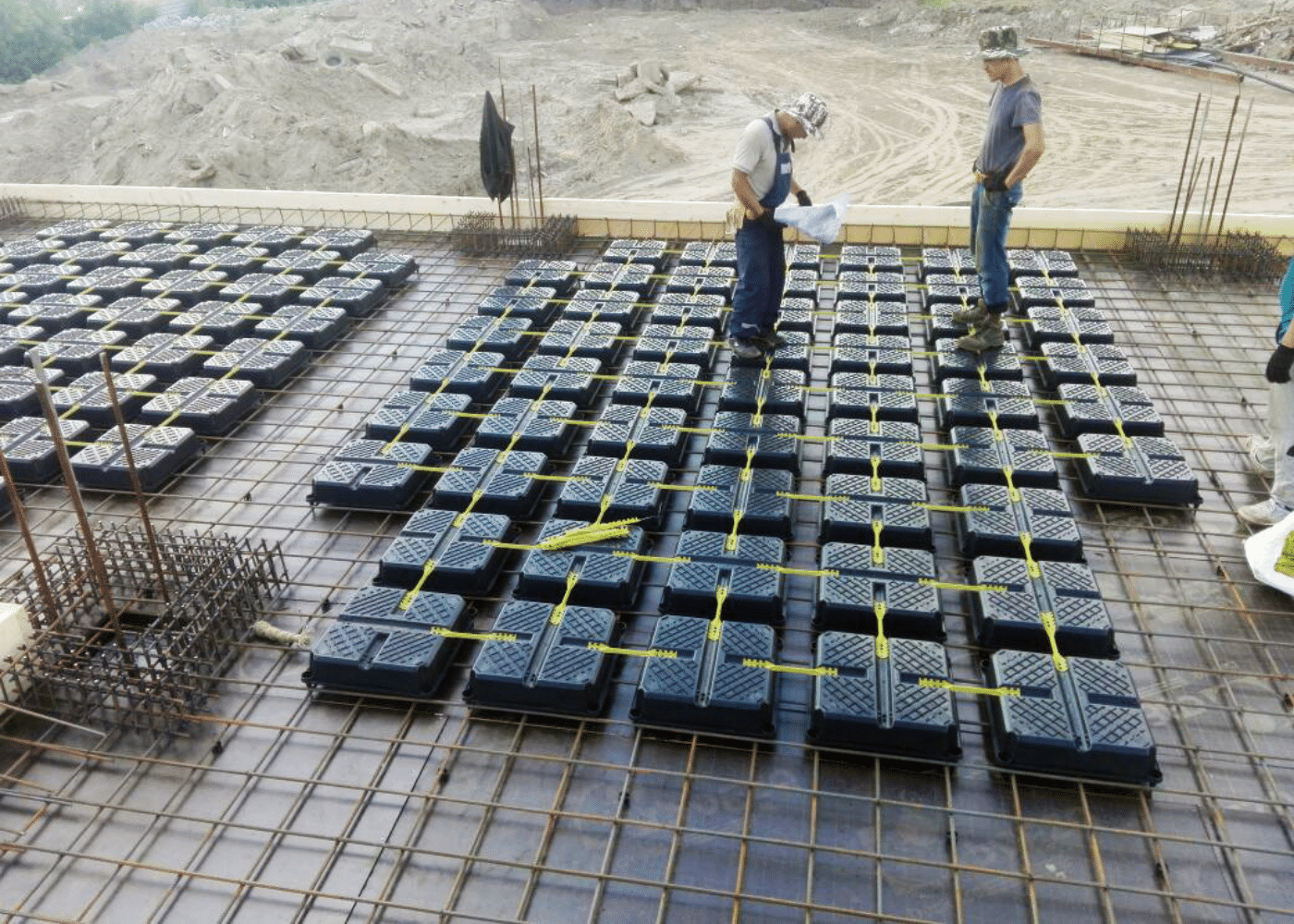

Modular EPS Void Systems:

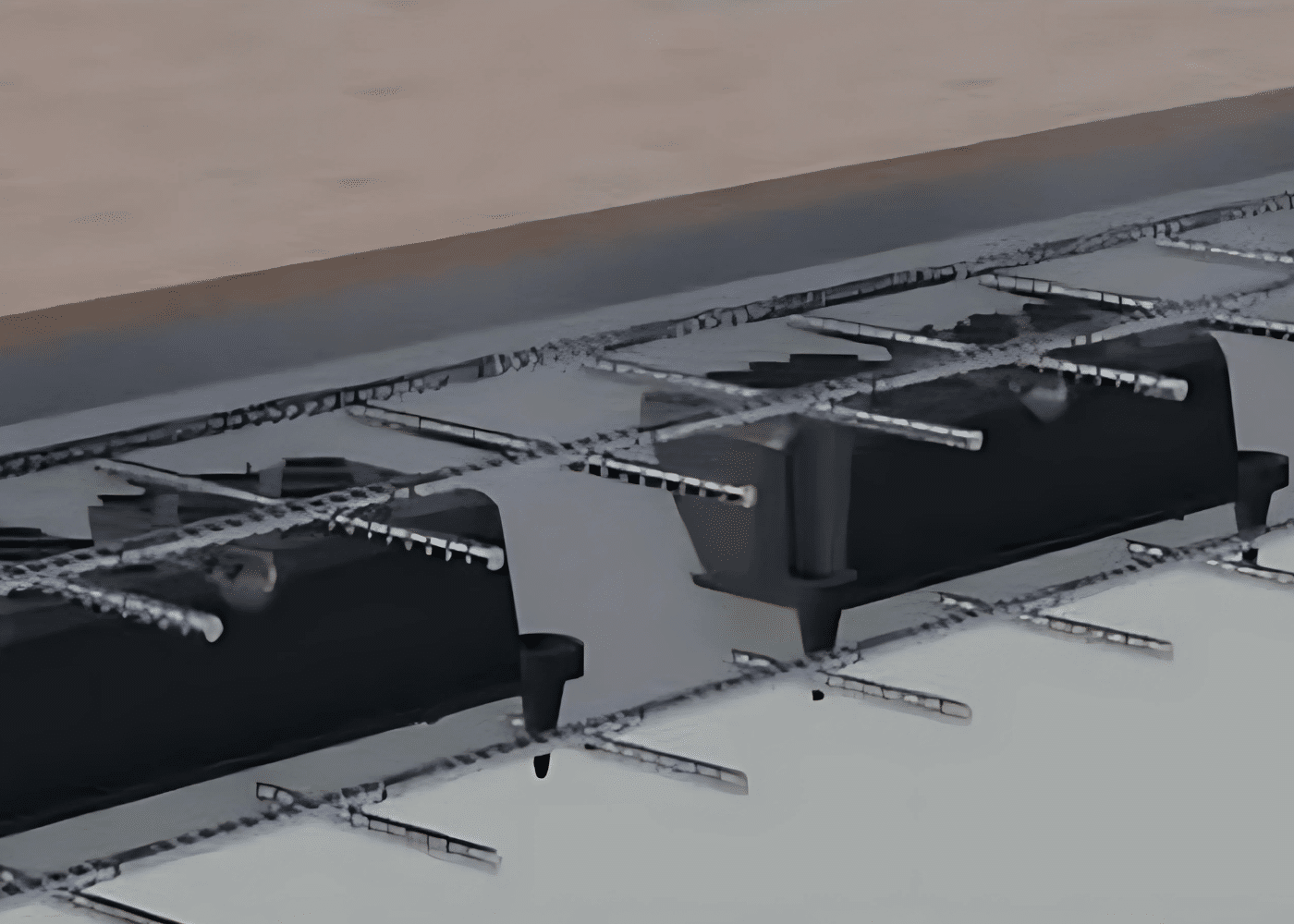

Moulded expanded polystyrene units are shaped to reduce the slab’s self-weight. These are often installed between rebar layers in two-way or one-way slabs.

Examples: Dome- or waffle-shaped modules, installed to create ribbed slab patterns.

Permanent Formwork with Voids:

These systems integrate structural and formwork elements. The void modules remain embedded in the slab after pouring, serving both as permanent formwork and as part of the structural system.

Example: Plastic modular systems used in two-way lightened slabs, offering high structural stiffness and reduced volume.

Compressible Structural Fill for Ground Heave Protection:

In expansive soil zones, compressible fill blocks protect structural elements from upward soil pressure. EPS boards are the most common choice due to predictable compressibility and high deformation control.

Key Benefits of Void Formers

1. Structural Efficiency

- Reduce dead load by up to 30–35%, enabling more slender floor systems

- Lower rebar requirements by up to 40%

- Reduce overall building weight by up to 10%

2. Cost-Effective Construction

- Lower volume of concrete and reinforcement = lower material cost

- Faster installation due to modularity and simple placement

- Reduced transport and crane loads due to lightweight material

3. Protection from Soil Movement

- Act as compressible fill against ground heave in clay-rich soils

- Help mitigate lateral pressure in expansive or shifting subgrades

- Suitable for both new foundations and building refurbishments

4. Durability and Sustainability

- EPS is moisture-resistant, inert, and non-biodegradable—ensuring long service life

- Reduces the need for more traditional fill materials like gravel or sand

- Fully recyclable and suitable for temporary or permanent applications

Structural Considerations

Using void formers requires careful structural design, often in collaboration between geotechnical and structural engineers.

Compressive Strength

EPS void formers are available in compressive strengths typically covering most load-bearing needs for slabs, beams, and foundations. Selection depends on:

- Slab thickness

- Type of reinforcement

- Location of voids

- Expected live loads

Load Transfer

Since void formers reduce the volume of concrete, careful design is required to maintain structural performance:

- Adequate load distribution across slab ribs or solid zones

- Sufficient shear and flexural strength at critical interfaces

- Control of punching shear, especially around columns and load-bearing areas

- Monitoring of differential deflection between voided and solid zones, particularly in large-span slabs, to ensure serviceability and long-term performance

Two-way lightened slabs using dome-shaped voids must be carefully detailed at columns and beam intersections to avoid weak zones.

Fire and Moisture Resistance

While EPS has excellent moisture resistance, its performance in fire must be accounted for in the design. Fire-rated covers or concrete minimum covers are used to meet code requirements.

Applications in Modern Construction

Void formers are widely used in:

1. Reinforced Concrete Floor Slabs

Modular EPS domes create grid-like ribbed slabs with high bending capacity. This is common in:

- Commercial buildings

- Parking garages

- Warehouses

- Airports and transport hubs

These slabs maintain flat soffits for easier MEP installations and lower ceiling heights.

2. Ground Beams and Foundations

In expansive clay zones, compressible EPS sheets under beams and slabs provide heave protection, reducing pressure buildup and cracking.

3. Infrastructure Projects

Bridge decks, tunnels, and elevated roadways benefit from voids in thick slabs to reduce weight and material use.

4. Forming Openings and Temporary Structures

Void formers also act as placeholders for future access hatches, pipes, or electrical ducts, and are often used in temporary formwork applications due to their ease of removal.

Six Key Applications Examples of Void Formers

Drawing from real-world project experience, the use of void formers can be classified into six primary applications. These highlight the versatility of EPS void former systems across a range of building types:

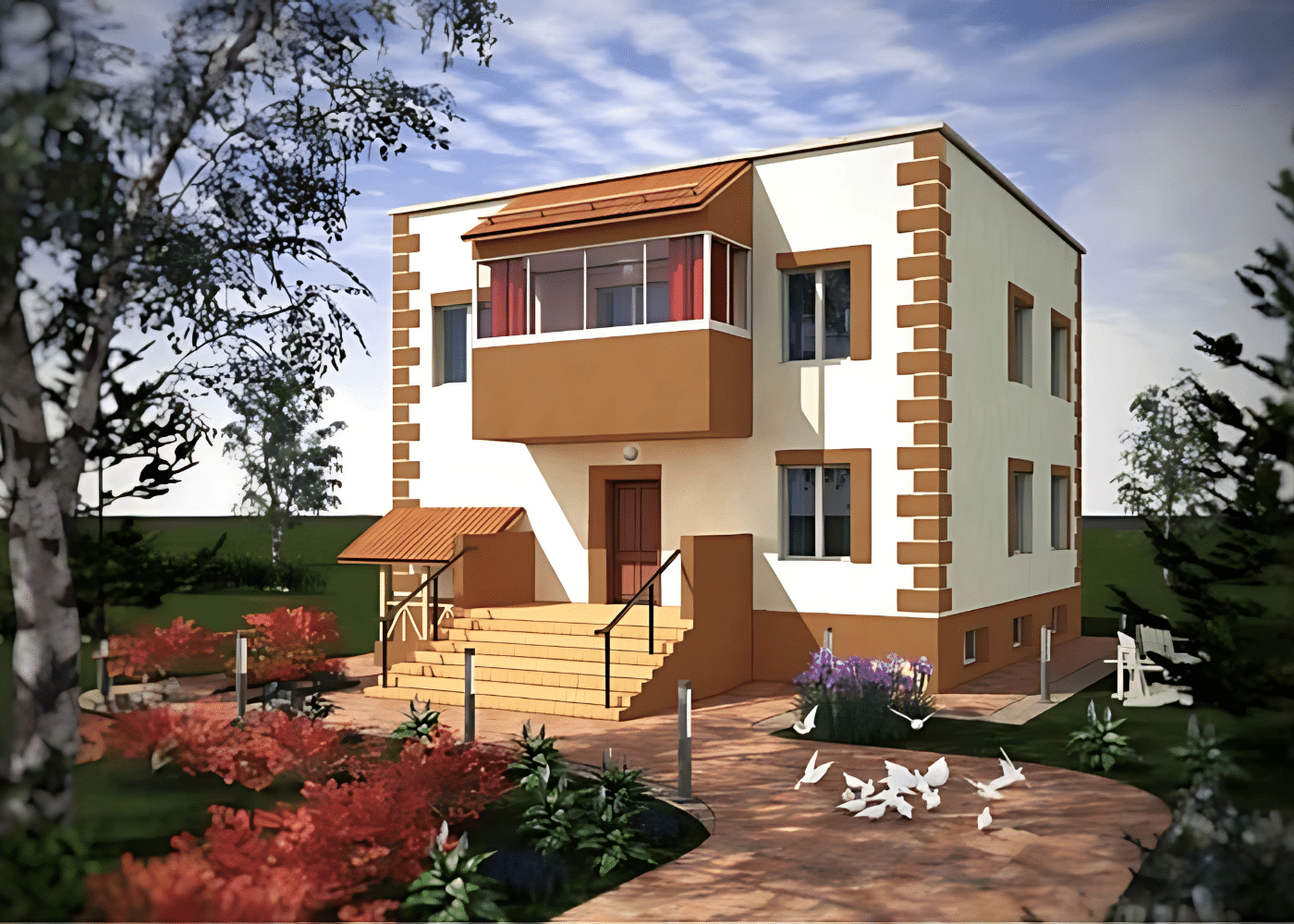

1. Low-Rise Buildings (1–3 Floors)

Void formers are used to create flat slab systems supported only by perimeter walls—eliminating internal columns and enabling open-plan designs.

Use Case: Residential buildings, shops, small community centres, and warehouses

Design example:

Benefits:

- Column-free interiors

- Reduced excavation and foundation loads

- Faster construction timelines

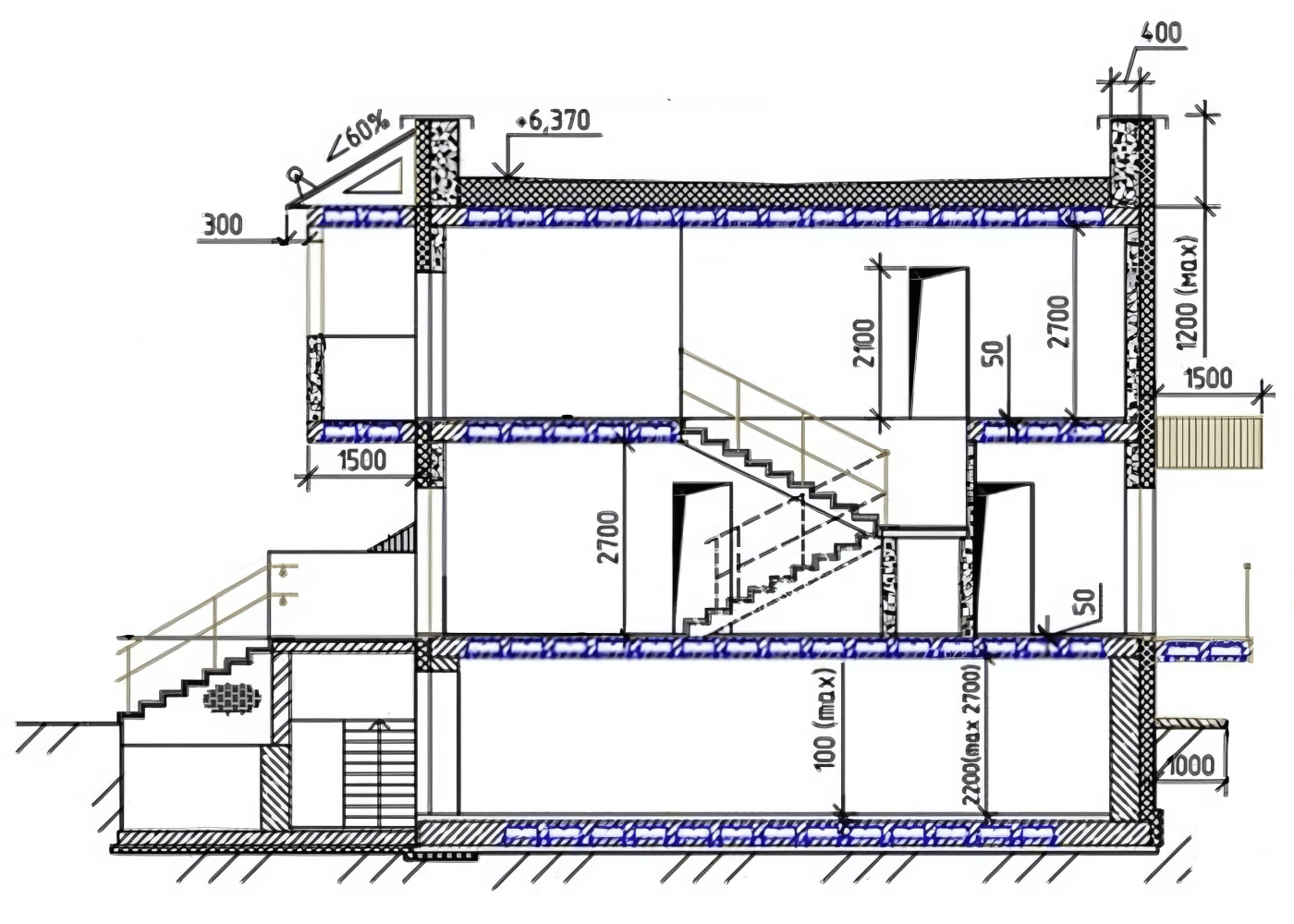

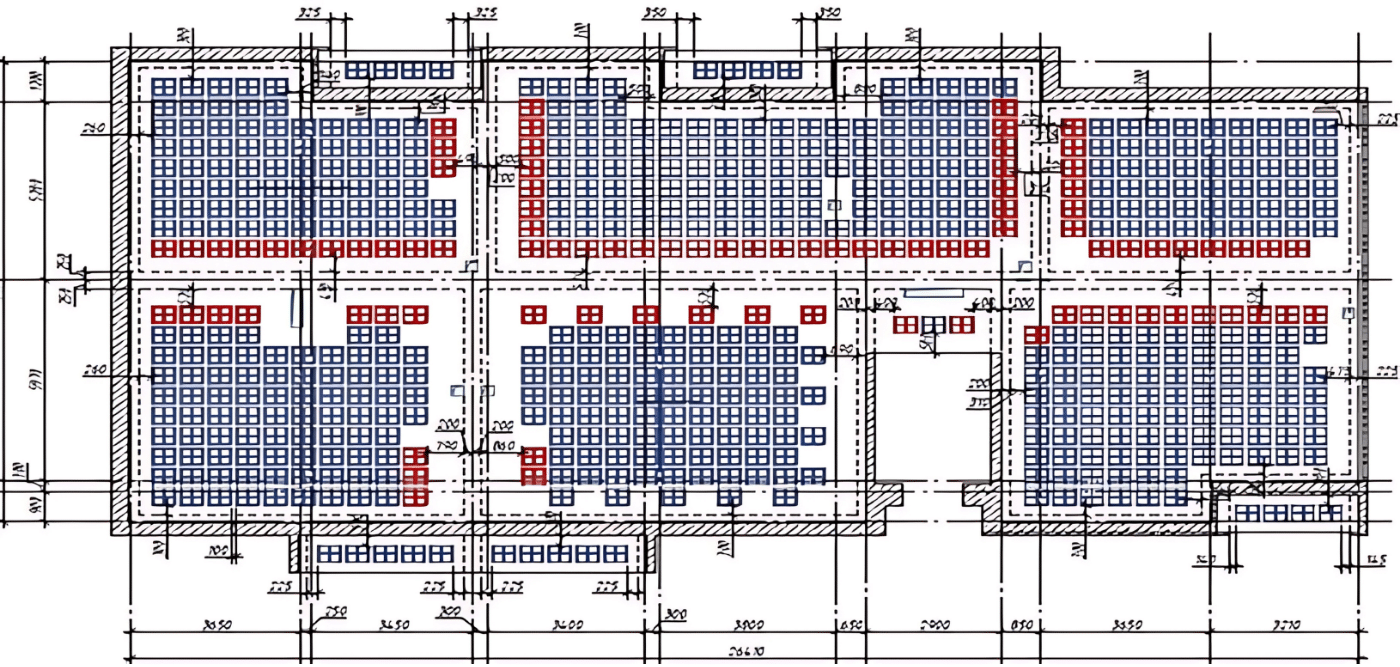

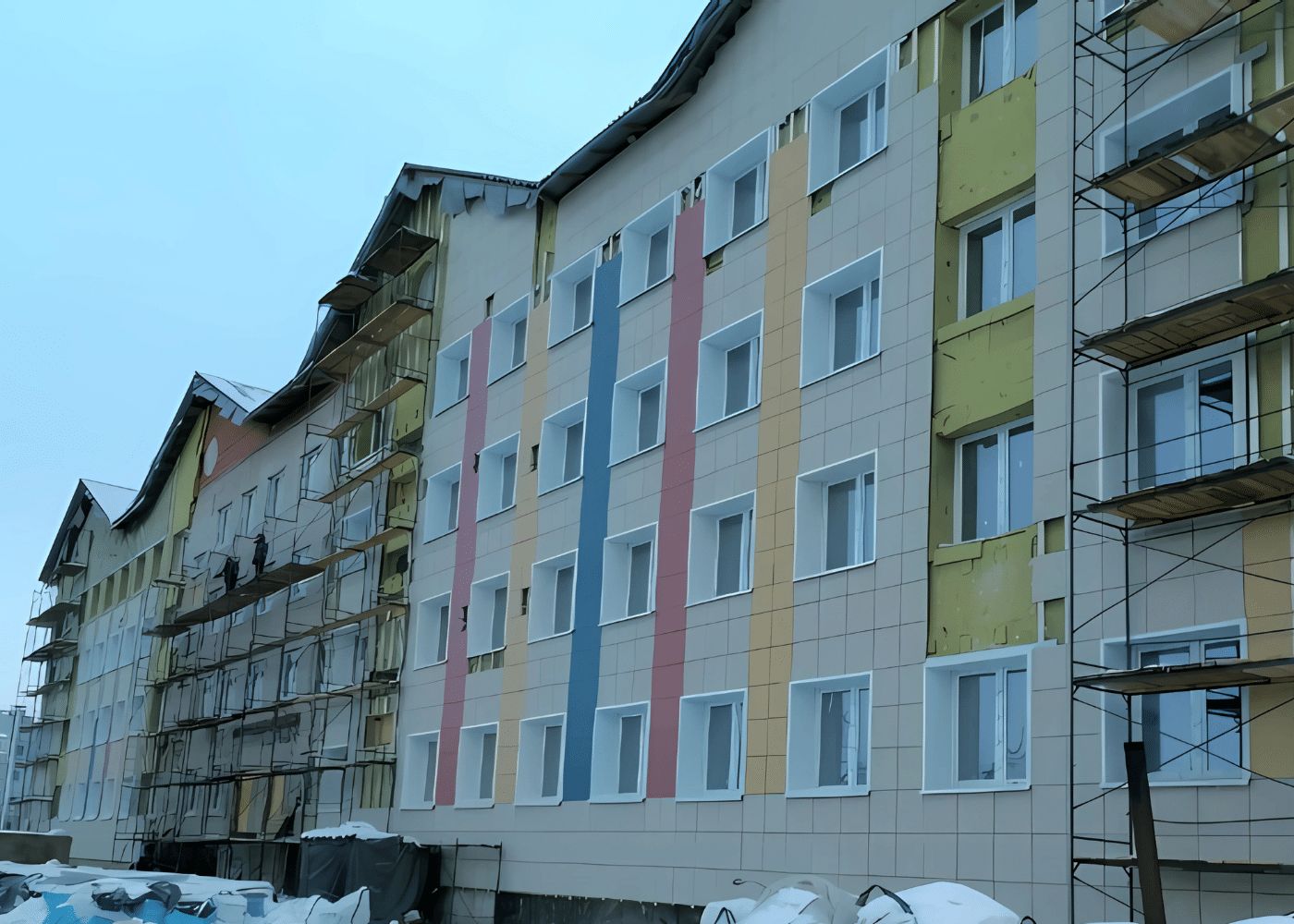

2. Mid-Rise Wall-Bearing Structures (4–7 Floors)

EPS-based voided slabs allow for lightweight floor systems that complement aerated concrete (AAC) wall construction, commonly used in mid-rise housing developments.

Use Case: Apartment blocks, student housing, compact commercial buildings

Design example:

Benefits:

- Cost-effective foundations due to reduced slab weight

- No additional façade insulation required

- Clean finish: “plaster, paint, and forget”

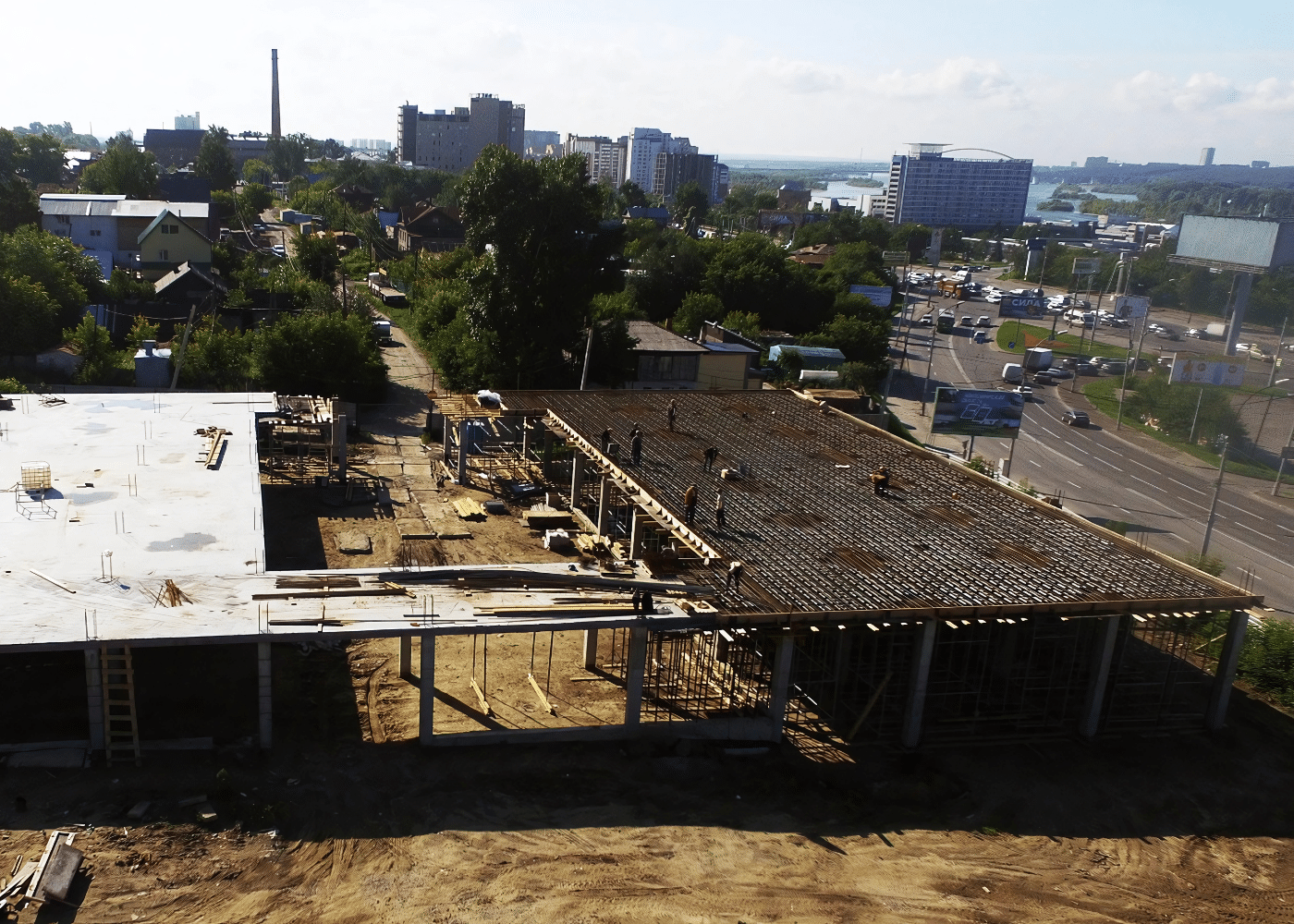

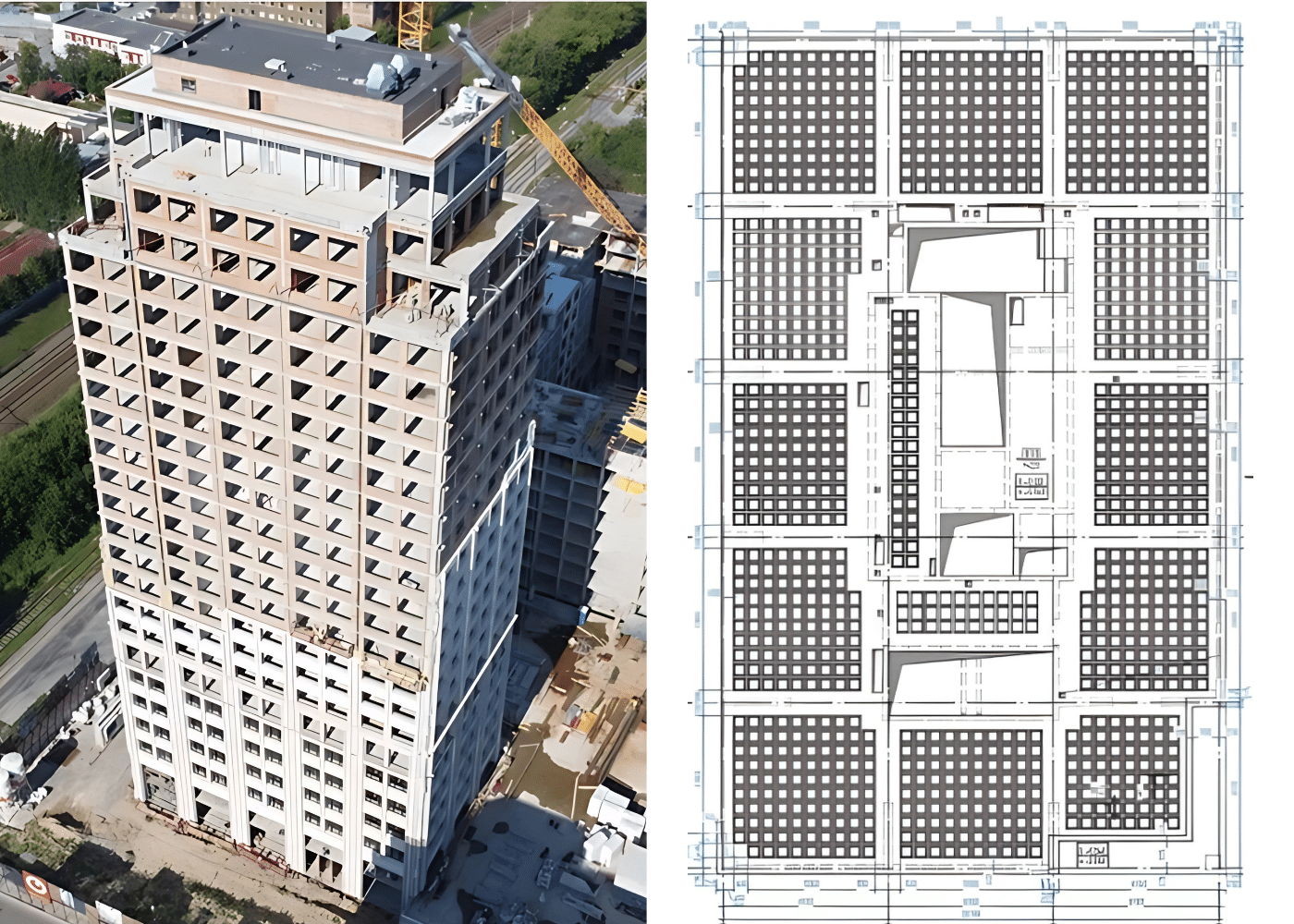

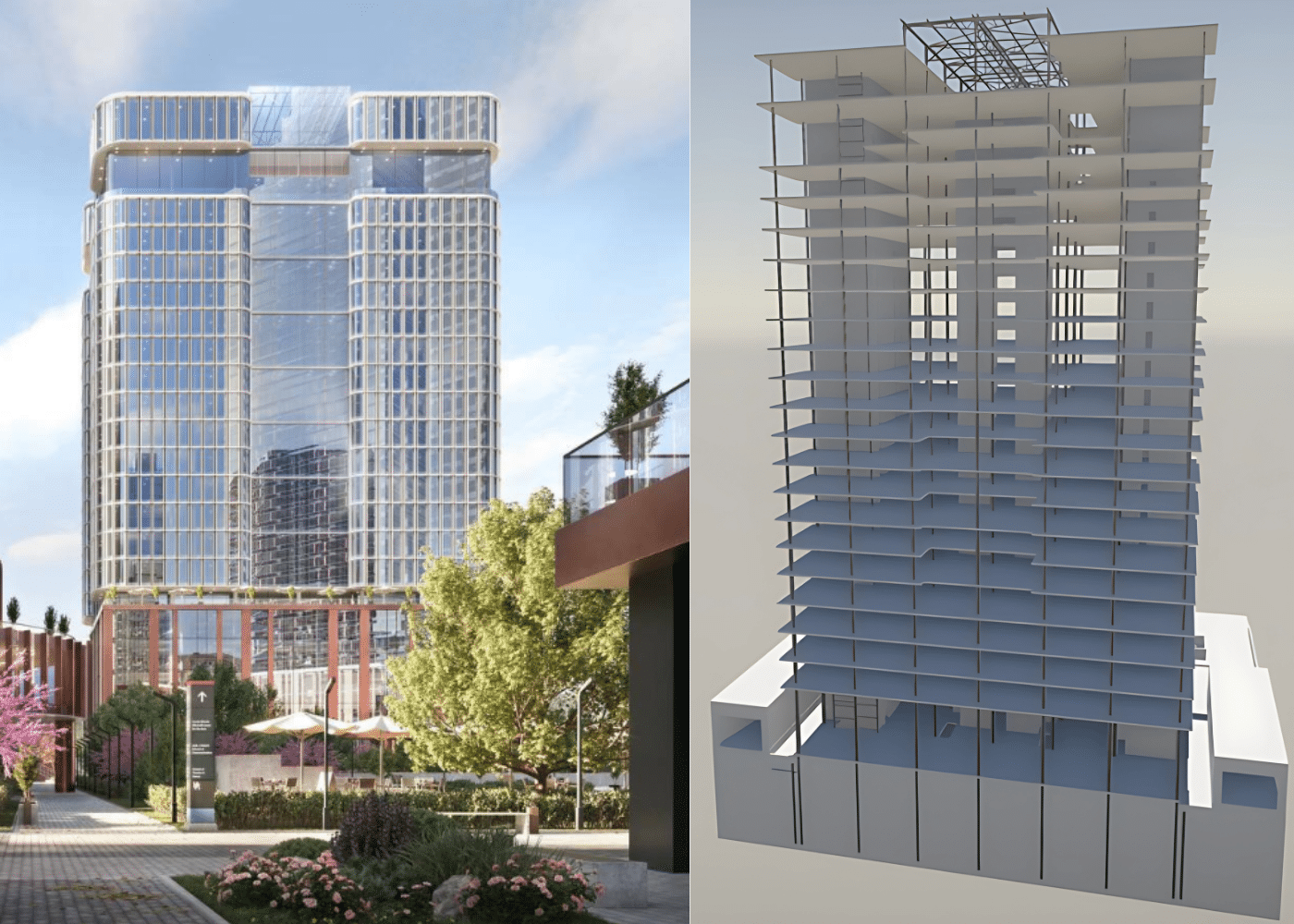

3. Monolithic High-Rise Buildings (8–25 Floors)

In multi-story buildings with cast-in-place concrete frames, void formers reduce slab dead weight without impacting load-bearing capacity.

Use Case: Residential towers, mixed-use developments, commercial complexes

Benefits:

- Large span coverage (500–600 m² per floor)

- Improved load distribution with reduced structural cross-sections

- Simplified floor plan standardisation across levels

4. High-Rise and Landmark Buildings

Cutting-edge projects combine voided slabs with steel-concrete composite columns or tube-in-tube systems for high-load structures.

Use Case: Skyscrapers, office towers, public infrastructure hubs

Design example:

Benefits:

- High-performance slabs with integrated MEP channels

- Minimised slab thickness (as low as 400–500 mm)

- Flexibility in designing atriums and open spaces

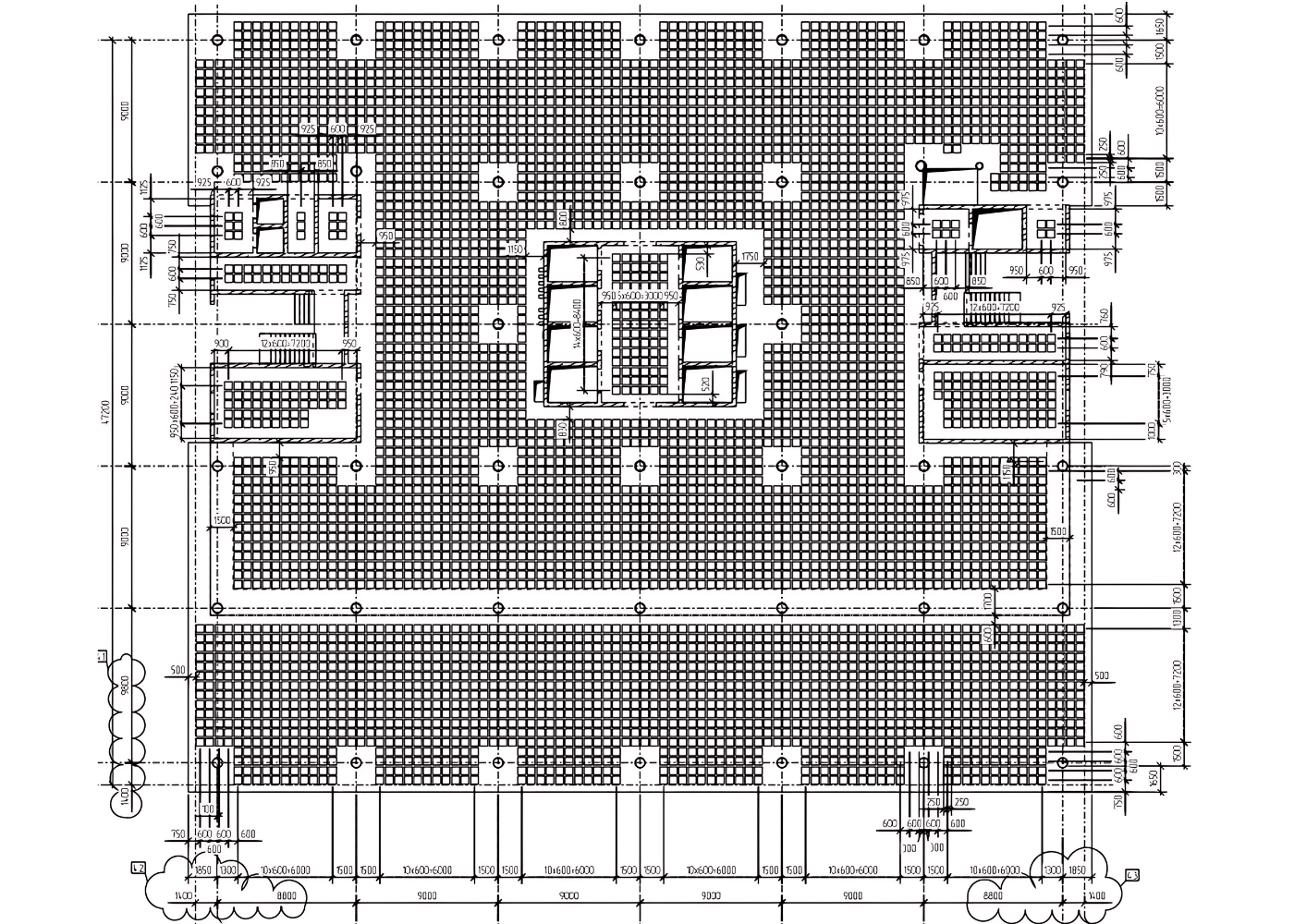

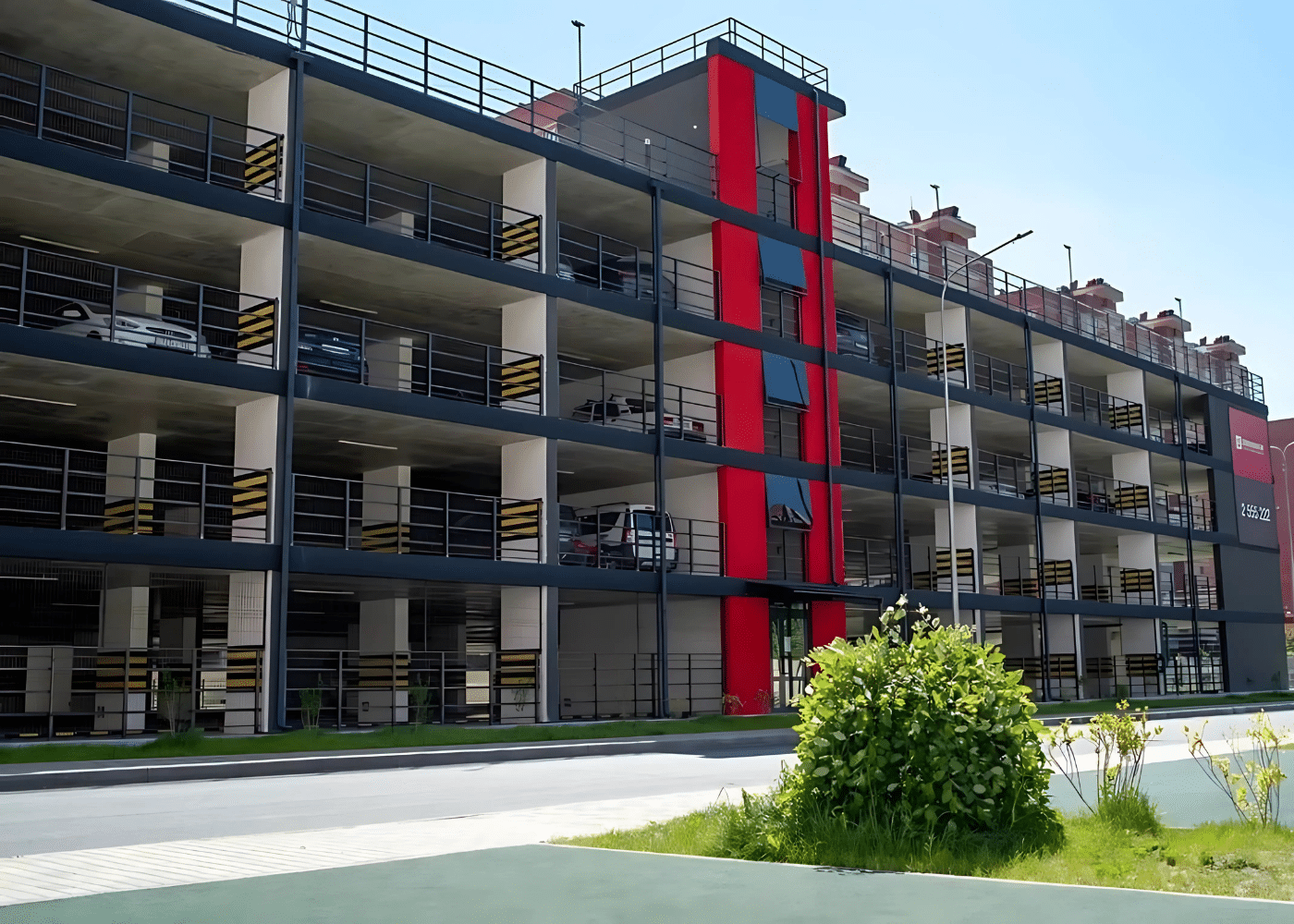

5. Parking Garages (Underground or Elevated)

Void formers enable flat-slab parking solutions without beams or capitals, maximising usable parking space and simplifying floor layouts.

Use Case: Urban parking decks, shopping centre garages, green-roof car parks

Project example:

Benefits:

- No dropped beams or restricted height zones

- Enhanced aesthetic and structural uniformity

- Green building options with rooftop landscaping

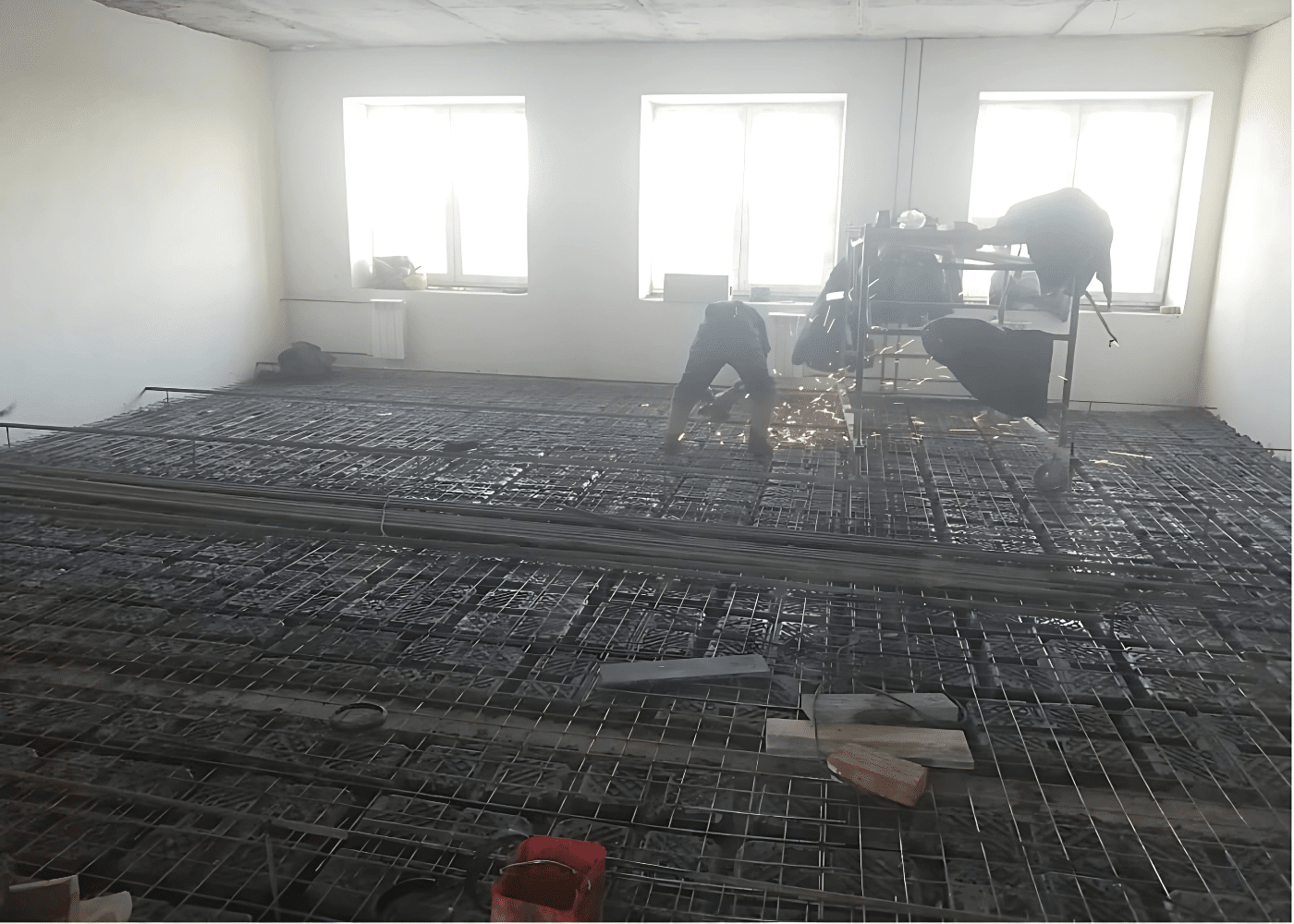

6. Building Renovation and Floor Re-Levelling

Void formers are also used in retrofitting older buildings to correct floor levels or reinforce existing slabs without overloading the structure.

Use Case: Schools, heritage sites, office retrofits

Project example:

Benefits:

- Easily installed above existing slabs.

- No need for demolishing old concrete

- Compatible with raised flooring systems and HVAC integration

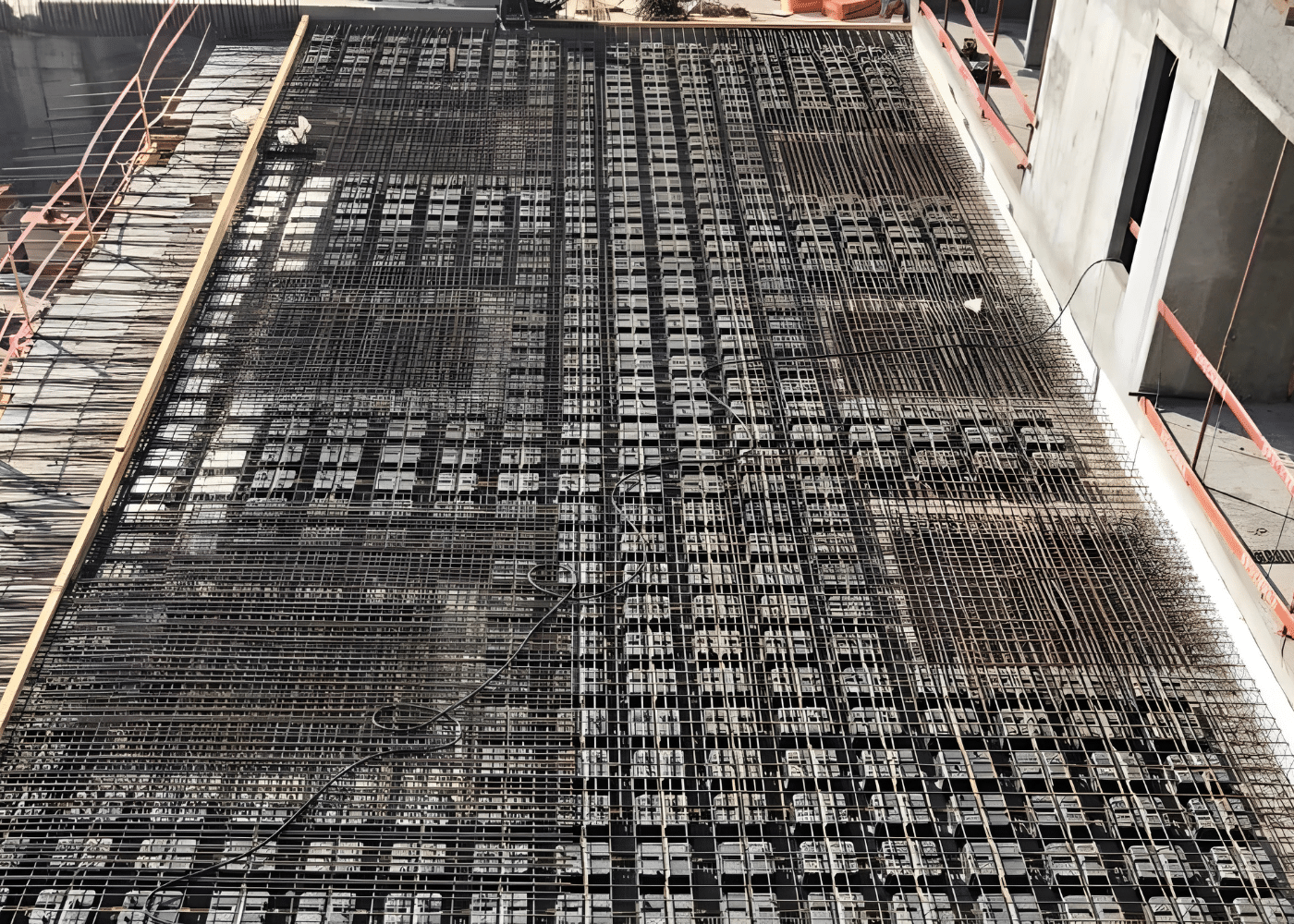

Installation Guidelines

Proper handling and installation of void formers are essential for performance:

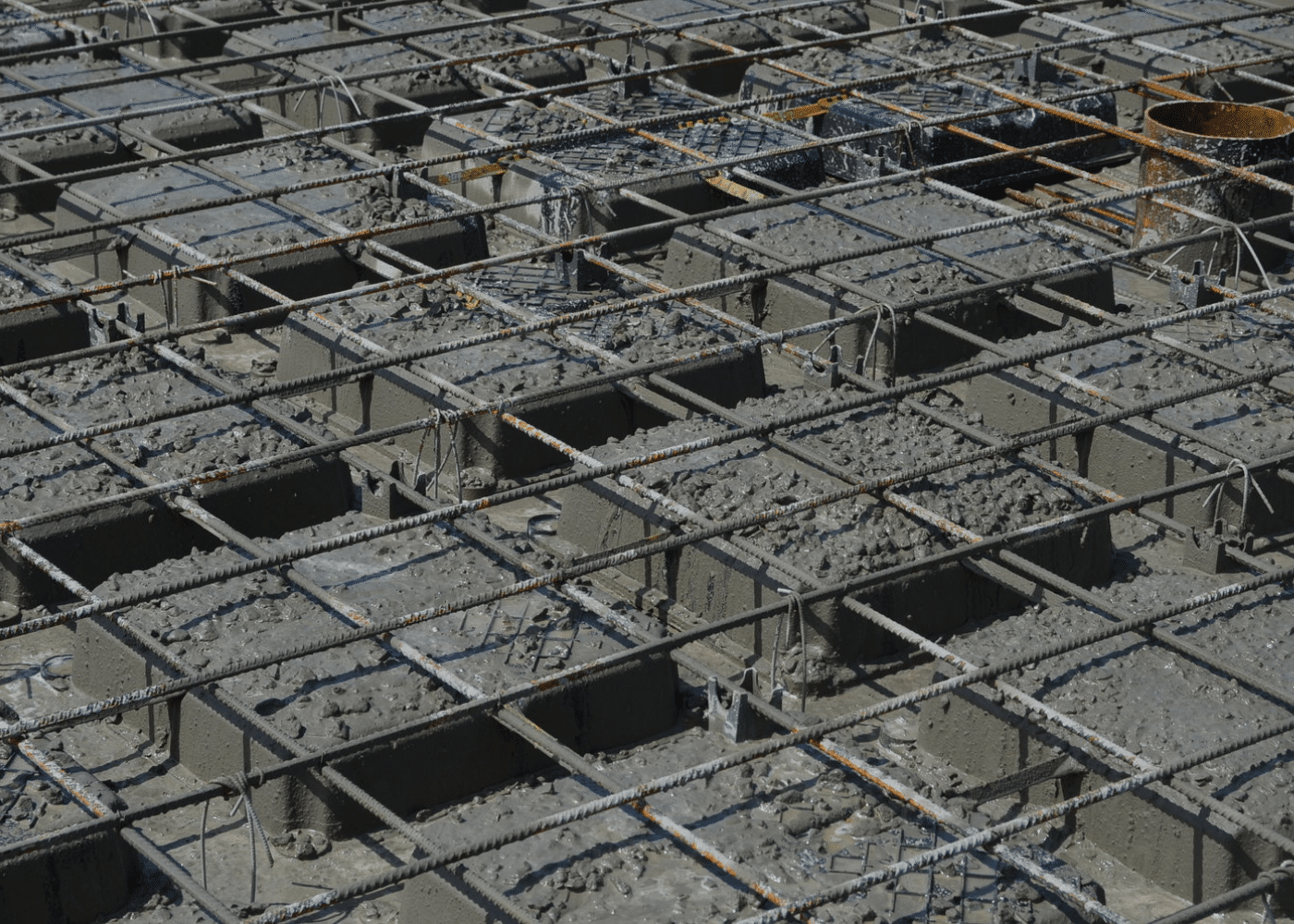

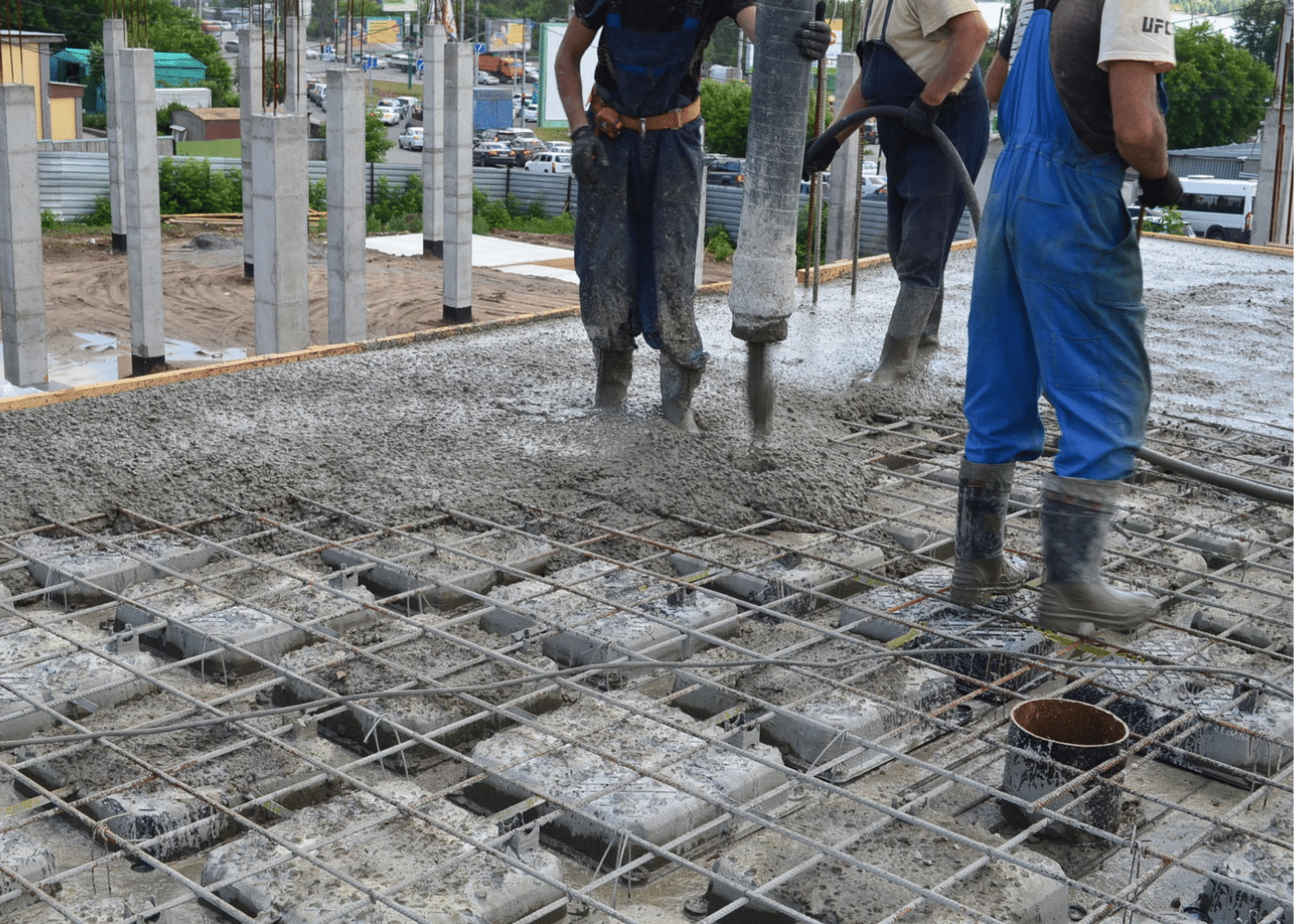

- Positioning: Void formers must be fixed securely to prevent flotation during the concrete pour.

- Spacing: Gaps between modules should match slab reinforcement spacing to ensure effective load paths.

- Reinforcement: Slabs with void formers typically have two mesh layers—top and bottom—with proper lap lengths and cover.

Concrete Pouring: Concrete should be poured in a controlled and steady manner to prevent displacement or damage to the void formers. Excessive vibration must be avoided, as it can crush or deform expanded polystyrene (EPS) modules, particularly those with lower compressive strengths.

To prevent flotation during casting, void formers should be mechanically fixed or weighted, and a two-stage pour is typically used:

Stage 1: Pour concrete up to approximately halfway up the height of the void formers.

Stage 2: Once the first layer has set sufficiently to provide resistance, the remaining concrete is poured to the final level.

This method ensures proper encapsulation, reduces pressure on the EPS, and maintains alignment of the reinforcement and slab profile.

Manufacturers provide project-specific detailing, including connection methods, module layout, and installation guides.

Comparison with Traditional Fill Materials

More traditional fill materials (e.g., gravel or lean concrete) are heavier, less adaptable, and offer no heave absorption properties. Void formers provide a modern alternative with significant advantages:

|

Feature |

Traditional Fill |

Void Formers (EPS) |

|---|---|---|

|

Fill Voidight |

Heavy |

Very lightweight |

|

Reusability |

No |

Often permanent or recyclable |

|

Heave absorption |

None |

Excellent |

|

Installation |

Manual-intensive |

Quick & modular |

|

Cost-effectiveness |

Low over lifecycle |

High |

Final Thoughts

Void formers are not just an innovation — they are an integral part of smarter construction. By reducing dead weight, simplifying MEP integration, and improving long-term resilience, they offer both design flexibility and lifecycle cost savings. As modern projects increasingly aim for efficiency and sustainability, incorporating lightweight void former systems is a forward-looking choice.

With the right product selection, engineering input, and proper installation, void formers can improve structural behaviour, simplify construction, and contribute to the long-term success of a project.

If you’re designing reinforced concrete floor slabs or dealing with problematic ground conditions, consider void formers not as an optional extra, but as a key component of smarter construction.