What We will Be Looking At:

-

The main steel sheet pile installation methods and when to use them;

-

Over-water sheet pile installation considerations;

-

Equipment selection and maintenance best practices;

-

Environmental and safety considerations for sheet piling;

Steel sheet piling is vital for construction projects, especially in challenging soil conditions or near water. Choosing the correct installation method and managing the equipment is key to a successful project. This article covers the main installation methods, over-water installation considerations, equipment management, and other vital factors for a sheet piling project.

Sheet Piles Installation Methods

Dynamic Installation (Impact Installation)

Dynamic installation involves forceful driving techniques that embed sheet piles quickly and efficiently. This process is ideal for dense soils or where speed is crucial, but it can also generate high noise and vibration levels.

Vibratory Driving (Vibratory Hammer): Vibratory hammers use oscillations to drive sheet piles into the ground. This method works well for softer or looser soils requiring less impact force. Vibratory hammers also produce less noise and ground disturbance than impact hammers, making them ideal for projects in populated areas, near adjacent properties, or sensitive structures.

Impact Driving (Impact Hammer): Impact hammers (hydraulic or diesel hammers) deliver powerful, repeated blows to drive longer piles into dense or rocky soils. High penetration force makes them suitable for hard ground conditions. However, noise and vibration levels can be high, so impact hammers require soil investigation and site assessment to avoid disturbing nearby structures or environments.

Pros of Dynamic Installation:

-

Fast and effective sheet pile installation for a variety of soil types

-

Ideal for projects that require rapid installation

Cons of Dynamic Installation:

-

High noise and vibrations may affect sensitive areas.

-

It is less precise than static methods and requires correct alignment to avoid issues with interlocking edges.

Static Pile Jacking (Hydraulic Pressing)

Static pile jacking, or hydraulic pressing, uses steady, controlled force to push sheet piles into the ground without vibration. This method is suitable for noise-sensitive or ecologically fragile areas.

Hydraulic Pressing: Hydraulic jacks press sheet piles slowly and steadily into the ground without impact or vibration. This precise method minimises disruption to nearby structures, making it a good choice for urban projects and areas near hospitals, schools, or residential zones.

Pros of Static Pile Jacking:

-

Quiet and non-disruptive

-

It provides precise control, ensuring proper position and alignment.

Cons of Static Pile Jacking:

-

It is slower than dynamic methods, which may extend the project duration.

-

Higher initial equipment cost but noise-related delays may offset this over time.

Alternative Installation Methods

In addition to dynamic and static methods, there are other methods used in specific soil conditions or project requirements:

-

Jetting: This method uses water or air jets at the toe of the pile to help drive sheet piles into soft or sandy soils. Jetting reduces soil friction so sheet piles can be driven to the required depth without high force.

-

Pre-Drilling: In very dense or rocky soils, pre-drilling may be required to create an initial hole for sheet piles. This ensures smoother installation and reduces wear on rigs and other equipment.

-

Panel Driving: A technique where sheet pile wall is installed as pre-assembled panels, ensuring uniformity and speed for large-scale projects. Templates are often used to guide and align piles during installation.

Over-Water Considerations for Sheet Pile Installation

Installing sheet piles over water requires extra planning due to environmental factors like tides, currents, and site geology. Specialised equipment like pile-driving barges and support vessels are needed to manage these conditions.

Tips for Over-Water Piling:

Avoid Mid-Construction Extensions: Extending sheet pile lengths mid-construction in over-water projects can destabilise the structure due to water movement and cause misalignment or joint failure. To avoid this risk, plan the pile lengths and installation sequence.

Monitor Environmental Conditions: Tides, currents, and weather conditions can affect over-water installations. Continuous monitoring allows the technical team to adjust as needed to maintain stability and minimise delays.

Reinforce Piles: Reinforcing sheet piles after installation can help them withstand water flow and prevent movement due to external forces, especially in areas with strong currents.

Specialised Over-Water Equipment:

-

Spud Barges: These have retractable legs that anchor to the seabed and provide a stable platform to drive sheet piles into the water.

-

Crane Attachments: Lift and position piles accurately.

-

Template Frames: Frames can help to align and guide piles during installation to ensure they are driven accurately and securely.

Environmental Impact: Minimising environmental impact is critical for over-water projects. Use quiet equipment when possible and implement measures to protect water quality, like spill containment systems to avoid contaminating the surrounding environment.

Sometimes, trial installations or pilot piles may be required to test alignment and stability. These initial placements will ensure that the full installation goes smoothly without costly adjustments.

Equipment Management

Sheet piling projects rely heavily on having the right equipment in the proper condition. Contractors must ensure that equipment is well-maintained and suitable for the chosen drive method. Equipment selection, maintenance, operator training and inventory management are key to good equipment management.

Selection of Pile Driving Equipment

Selecting the right equipment for each installation method (driving method) and site condition is critical. Here’s a quick guide:

Vibratory and Impact Hammers: Vibratory hammers are better for soft soils, while impact hammers are better for dense or rocky soils. They are used for dynamic installation in varied soil conditions.

Hydraulic Jacking Systems: Ideal for static piling in sensitive environments as they provide controlled and quiet installation.

Specialised Over-Water Equipment: Equipment like pile-driving barges, support vessels, spud barges and template frames are needed for over-water projects.

Routine Maintenance

Regular maintenance and timely repairs are crucial to avoiding breakdowns, safety and extending equipment life.

-

Daily Checks: Check fluid levels, hydraulic lines and safety mechanisms before use.

-

Weekly Inspections: Lubricate joints, inspect wear points and make minor adjustments.

-

Monthly or Quarterly Checks: Do full maintenance on high-use equipment, test all safety and hydraulic systems and inspect for any signs of wear and tear or damage.

Operator Training

Properly trained operators are key to safe and efficient equipment use. Training should cover each machine’s limitations, safety protocols and operational requirements to minimise misuse and equipment failure.

Assigning Equipment Managers

Having an equipment manager can be very useful for overseeing equipment selection, leasing, usage and repairs. This role will ensure equipment is managed well and prevent delays and project timelines.

Inventory Management

Keep spare parts in the inventory so that critical components are available for repair when needed. Having spare parts on hand minimises downtime and keeps the project running smoothly.

Safety and Compliance

Equipment should be safety certified (OSHA or CE), and regular safety audits should be performed. This will ensure that all equipment meets regulatory standards and is safe for operators and surrounding structures.

Environmental and Safety Considerations

Environmental and safety compliance is key in sheet piling projects. Consider:

-

Noise Control: In sensitive areas, install sheet piles using quiet methods like static pile jacking or vibratory hammers to minimise disturbance.

-

Marine and Wildlife Habitats: Use noise-dampening barriers or containment measures to protect nearby habitats from noise and pollution.

-

Emergency Response Plans: Establish and communicate emergency procedures, especially for over-water projects where unpredictable factors like tides or weather can affect safety.

-

Personal Protective Equipment (PPE): Require all operators and site workers to wear PPE, helmets, gloves, hearing protection and life vests for over-water installations.

Summary

A sheet piling project depends on choosing the correct installation method, managing equipment well and planning for site-specific challenges. Dynamic and static installation methods offer flexibility for different soil types and environmental conditions; over-water piling requires extra planning and specialised equipment. Regular maintenance, proper training, and environmental considerations will ensure that each project is done safely, efficiently, and sustainably.

With proper planning, right equipment selection and comprehensive safety measures, sheet piling can provide a strong and stable foundation that will last for years to come. Talk to a sheet piling expert to customise your project to your site conditions and regulatory requirements.

Related Products from Aema Steel

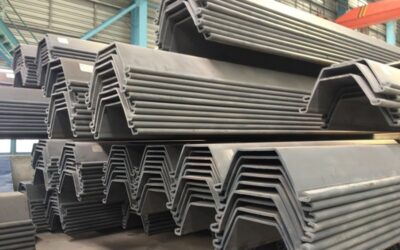

- Hot Rolled U Type Sheet Piles

- Hot Rolled Z Type Sheet Piles

- Cold Formed U Type Sheet Piles

- Cold Formed Z Type Sheet Piles

- Steel Pipe Piles

- Welded H Piles

Contact us today to receive a tailored offer for your upcoming project.