What we will look at:

-

Sheet piling design considerations

-

Pre-project checks

-

Choosing materials and profiles for your project

Good design is key to a successful sheet piling project. Proper planning and design will ensure the base is strong and long-lasting, whether it’s small retaining walls or large waterfront installations. This article will look at the key design considerations so you can make informed decisions on sheet piling for your project.

Sheet Piling Design Considerations

1. Soil

The soil at the site significantly impacts the design and choice of steel sheet piles. Different soils have different stability and load-bearing properties, affecting the sheet piles’ thickness, material, and section.

Loose or Sandy Soils: These may require thicker piles or additional support measures to prevent movement.

Dense or Rocky Soils: Due to increased resistance, these may require special equipment, like vibratory hammers and higher-strength piles, to ensure proper penetration of the piles into the ground.

Tip: Before selecting your sheet piles, conduct soil classification tests, such as borehole surveys.

2. Depth of Excavation

The depth of excavation has a direct impact on the structural load on the sheet pile wall. Deeper digs increase the pressure, often requiring thicker walls, higher-strength steel grades, and reinforced designs to ensure stability.

Tip: Include bending moment and shear resistance calculations in your design to check the pile strength at greater depths.

3. Water Table Level

High water tables can make installation more difficult and increase the risk of water ingress, undermining the foundation’s stability. Water management solutions are essential for projects near water sources or areas with elevated groundwater.

Water-Resistant Sealants: Prevent seepage through pile joints (interlock).

Drainage Solutions: Direct water away from the structure, preventing water accumulation around the sheet piles.

4. Load Requirements

Calculating load requirements will ensure that the chosen sheet piles can take vertical and lateral loads. This is especially important for high-pressure projects such as waterfront developments.

-

Anchor Design: Properly designed anchors can provide additional lateral support to stabilise the structure against high loads.

-

Bearing Piles: For vertical loads, combining sheet piles with bearing piles may be required for maximum stability.

5. Environmental Conditions

Environmental factors such as groundwater, soil instability, and seasonal changes (e.g., freeze-thaw cycles) can affect the long-term durability of the sheet piling project.

Groundwater and Soil Instability: This can weaken the foundation over time and require corrosion protection methods.

Freeze-Thaw Cycles: In colder climates, seasonal soil expansion and contraction can influence the stability of the piles, potentially causing cracks or movement.

6. Regulatory Standards

Compliance with local building codes, industry standards and environmental regulations (e.g. EN 10248 for European projects) will ensure the project meets legal and safety requirements. Compliance will prevent rework and guarantee that the structure meets industry standards.

Tip: To avoid project approval delays, check regulatory standards earlier in the design phase.

Examples of Standards: In addition to EN 10248, other standards, such as ASTM A572 for high-strength steel or BS EN 1997-1:2004 for geotechnical design in the UK, may apply depending on the location and project requirements.

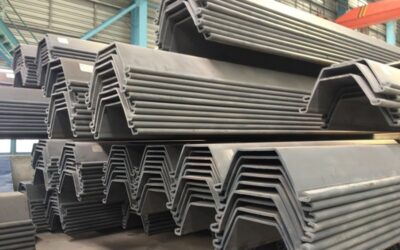

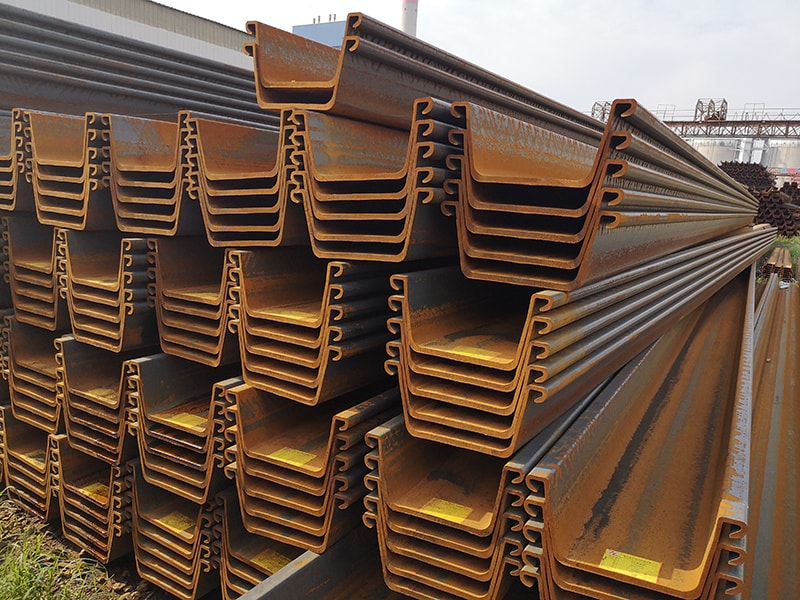

7. Material Selection Steel Sheet Piles

Choosing the right material and shape for sheet piles is critical to meeting the project requirements. Hot-rolled and cold-formed sheet piles come in different grades, sections, shapes, and thicknesses, each intended for a different application.

Hot-Rolled Sheet Piles: High strength and bending resistance make them suitable for heavy-duty projects and permanent structures.

Cold-Formed Sheet Piles: These are more flexible, cost-effective, and suitable for lighter applications or temporary structures.

A quick cost comparison:

-

Hot-rolled piles are more expensive but offer more strength and durability in complex and high-stress environments.

-

Cold-formed piles are a more budget-friendly option for projects where flexibility and cost savings are key.

8. Pre-Installation Site Survey

A pre-installation site survey is necessary for project managers and engineers to identify potential issues before the sheet piling installation starts. A detailed survey will help the team plan, minimise risks, and ensure a smoother installation process. Here are the key points to consider:

Obstructions:

The survey will detect underground obstructions like rocks, past structures or hard-buried utilities (e.g. pipes and cables). Finding these earlier will prevent delays and unexpected costs during installation. If obstructions are found, alternative piling methods or locations can be considered.

Nearby Structures:

The survey should consider the proximity of adjacent structures, such as buildings or roads, that may be affected by the vibrations and movements of the piling. This is especially important in urban areas where construction is close to existing structures. Surveyors can assess the impact and recommend techniques (e.g., vibratory hemmers, static pile jacking) that reduce vibrations and minimise risk to nearby buildings.

Environmental Sensitivities:

Some sites may have environmental concerns, such as protected wildlife habitats or sensitive ecosystems. Identifying these areas will allow the team to take steps to minimise environmental disruption. For example, quieter piling methods can avoid disturbing nearby wildlife, and erosion control measures can be implemented to protect the surrounding land and water bodies.

Soil and Groundwater Conditions:

In addition to general soil tests, the site survey will assess the groundwater levels and soil composition across the site. This information is critical to determine the sheet pile length and material required. High groundwater levels may require additional water management to prevent flooding or seepage.

Survey Equipment:

Advanced survey tools like GPS mapping, laser alignment and ground-penetrating radar are used to gather accurate data on the site conditions. These tools will create a precise site map so engineers can accurately plan the sheet pile alignment and depth.

Accessibility and Logistics:

The survey will also consider site accessibility to identify the best machinery access and material storage points. Proper planning is critical for project logistics, especially on tight, narrow sites or areas with limited space. It will ensure that equipment and materials can be transported safely and efficiently to and from the site.

Tip: A full site survey will set you up for a smooth installation so you can get the alignment right, place it securely and minimise the impact on the surrounding environment.

Conclusion

A sheet piling project starts with the design and planning phase. Engineers can make informed decisions on material selection and installation methods by considering soil type, excavation depth, water table level, and environmental conditions. Accurate design information and adhering to best practices will ensure proper pile alignment and penetration, creating a stable foundation.

When designed and planned correctly, sheet piling is a reliable long-term solution for many construction purposes. With the right design, your project will withstand environmental stresses and have a solid foundation for years to come.

Related Products from Aema Steel

- Hot Rolled U Type Sheet Piles

- Hot Rolled Z Type Sheet Piles

- Cold Formed U Type Sheet Piles

- Cold Formed Z Type Sheet Piles

- Steel Pipe Piles

- Welded H Piles

Contact us today to receive a tailored offer for your upcoming project.