Introduction:

When it comes to choosing the right steel pipe type for your project or application, understanding the different types and their unique properties is integral. It lays the foundation for a successful project. Each type of pipe has its set of advantages and is suited to particular environments and uses.

In this guide, we will delve into the top three most commonly used steel pipe types: seamless, welded, and casting pipes. When you are selecting steel pipe, it helps to understand how each type is manufactured, because the process largely determines strength, size range, cost, and best-fit applications. Below we break down how each type is manufactured, clarify a few common misconceptions, and share practical selection tips.

1. Seamless Pipes

What are the seamless pipes, and how are they made?

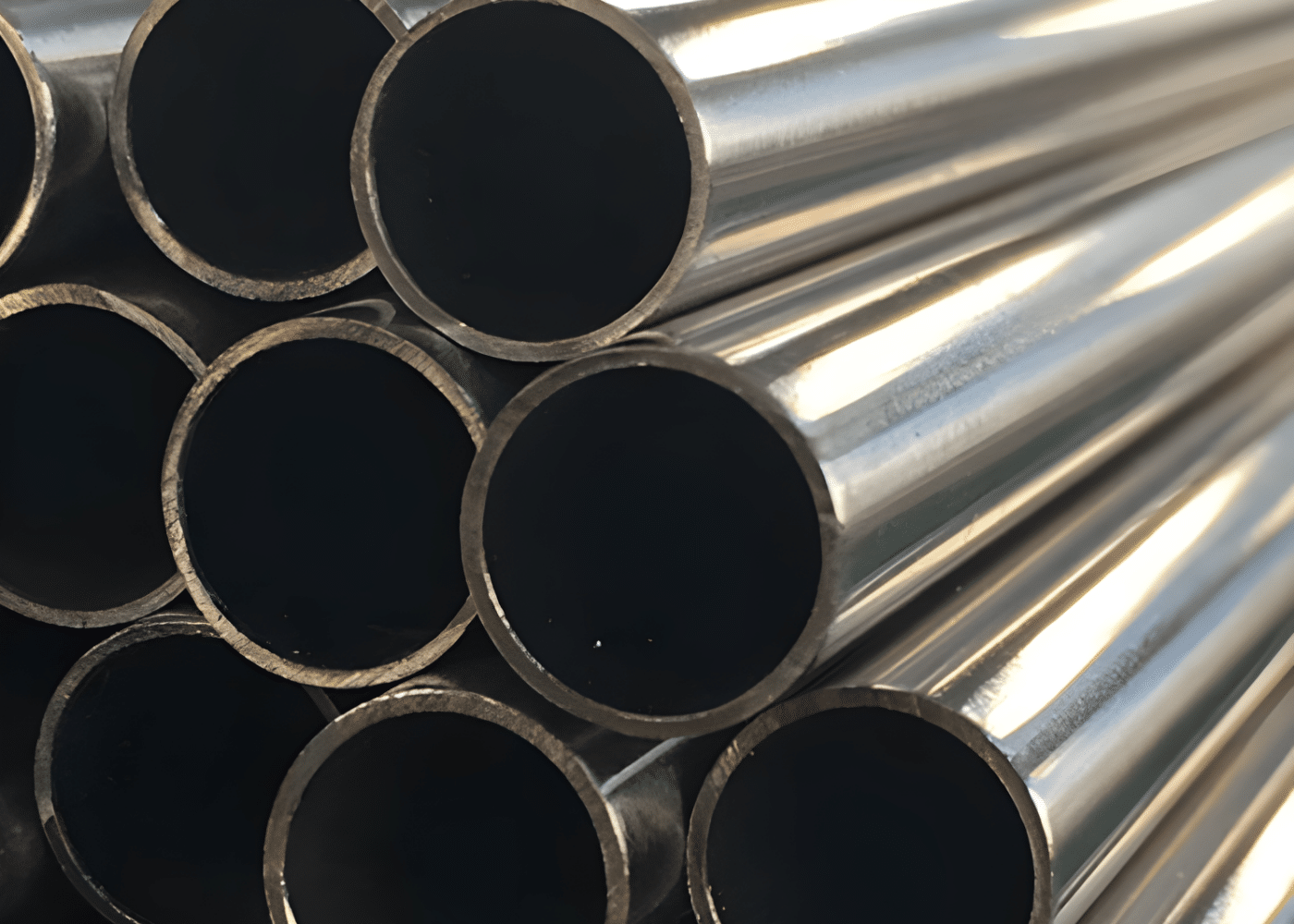

Seamless pipes are produced by heating and piercing a solid billet of steel to create a hollow tube, then elongating and rolling it (e.g., Mannesmann process). The result is a pipe with no longitudinal weld seam.

What are the typical sizes of seamless pipes?

- Outside diameter: 10.3mm – 762mm

- Wall thickness: 1.73mm – 30mm

- Lengths: Random Length, Fixed Length, SRL (single random length), DRL (double random length)

- Standards: ASTM A53/A106, A333, A335, EN 10216, EN10305, EN10210, ASME SA106/SA192/SA210, API 5L (seamless line pipe)

These sizes are available from Aema Steel. Contact us, and our specialists will assist you in selecting the most suitable size for your project

What are seamless pipes used for?

Seamless pipes can be used in a diverse range of applications, including oil and gas, fluid transport, industrial applications, automotive industry, shipbuilding, power generation industries, hydraulic systems, and construction.

Seamless pipes are ideal for high-pressure applications because of their strength and uniformity. Seamless pipes are less likely to leak or rupture due to their seamless construction. The absence of welded seams allows them to perform exceptionally well in high-stress environments under high-pressure and extreme temperature conditions. This is why seamless pipes are often preferred in critical applications, such as chemical and power plants, where safety is paramount.

Are the seamless pipes corrosion-resistant?

Corrosion resistance is not a function of being seamless, it depends on steel grade (chemistry) and coatings/linings. A seamless carbon-steel pipe will corrode just like a welded carbon-steel pipe in the same environment, unless it is protected.

2. Welded Steel Pipes

What are welded pipes and how are they made?

Welded steel pipes are manufactured from flat steel plates or coils, which are formed into a cylindrical shape and welded along the seam. Depending on the process, this seam can be either longitudinal or spiral.

Modern fabrication techniques such as Submerged Arc Welding (SAW) and Electric Resistance Welding (ERW) ensure consistent weld quality, often achieving strength equal to or exceeding that of seamless pipes when proper quality control standards (e.g., ultrasonic and radiographic testing) are followed.

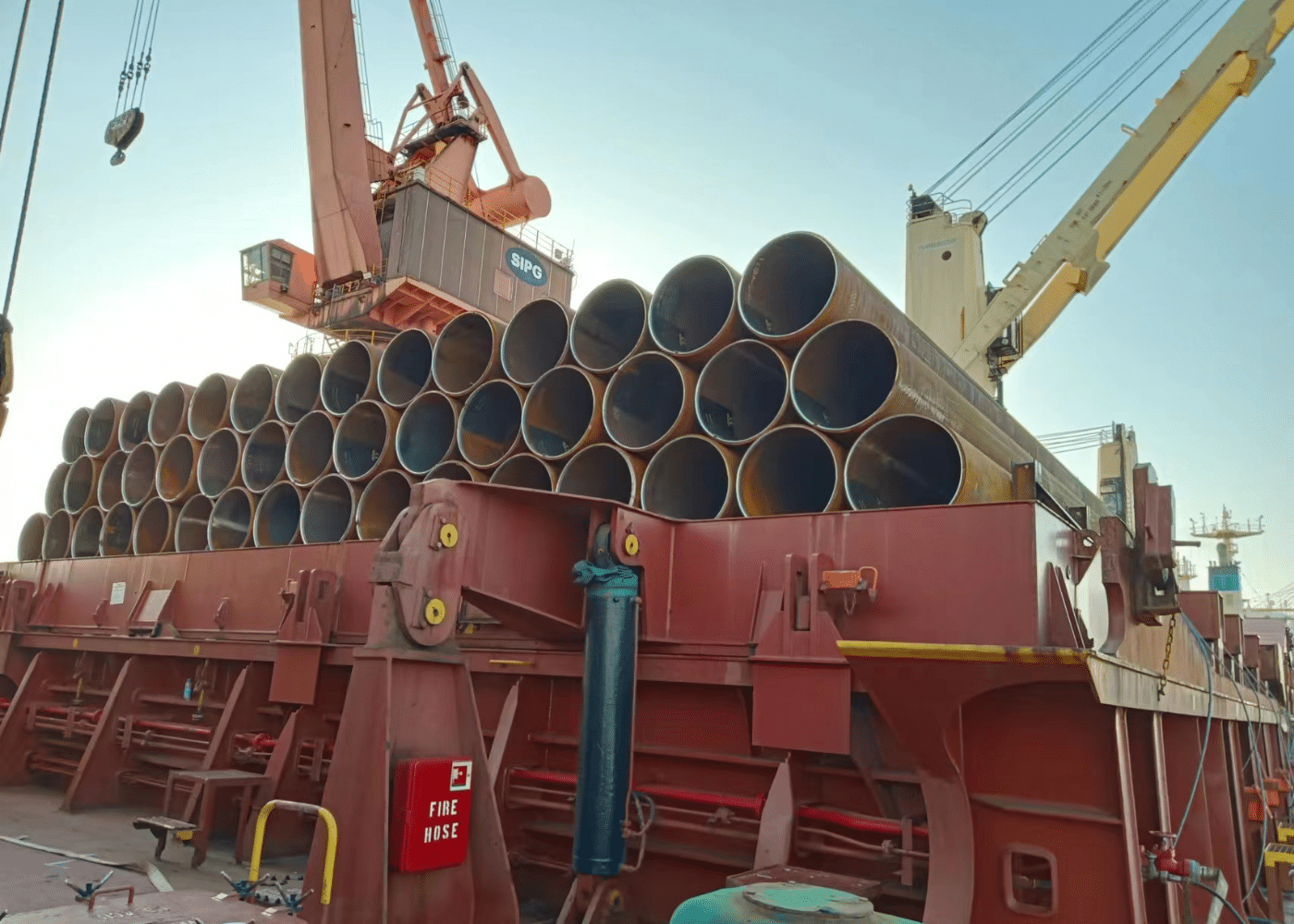

Welded pipe manufacturing method is typically faster and more cost-efficient than seamless production, making it ideal for large-diameter, long-length applications which are common in infrastructure and marine construction. The production of seamless pipes generally requires more energy compared to welded pipes.

What are the different types of welded steel pipes?

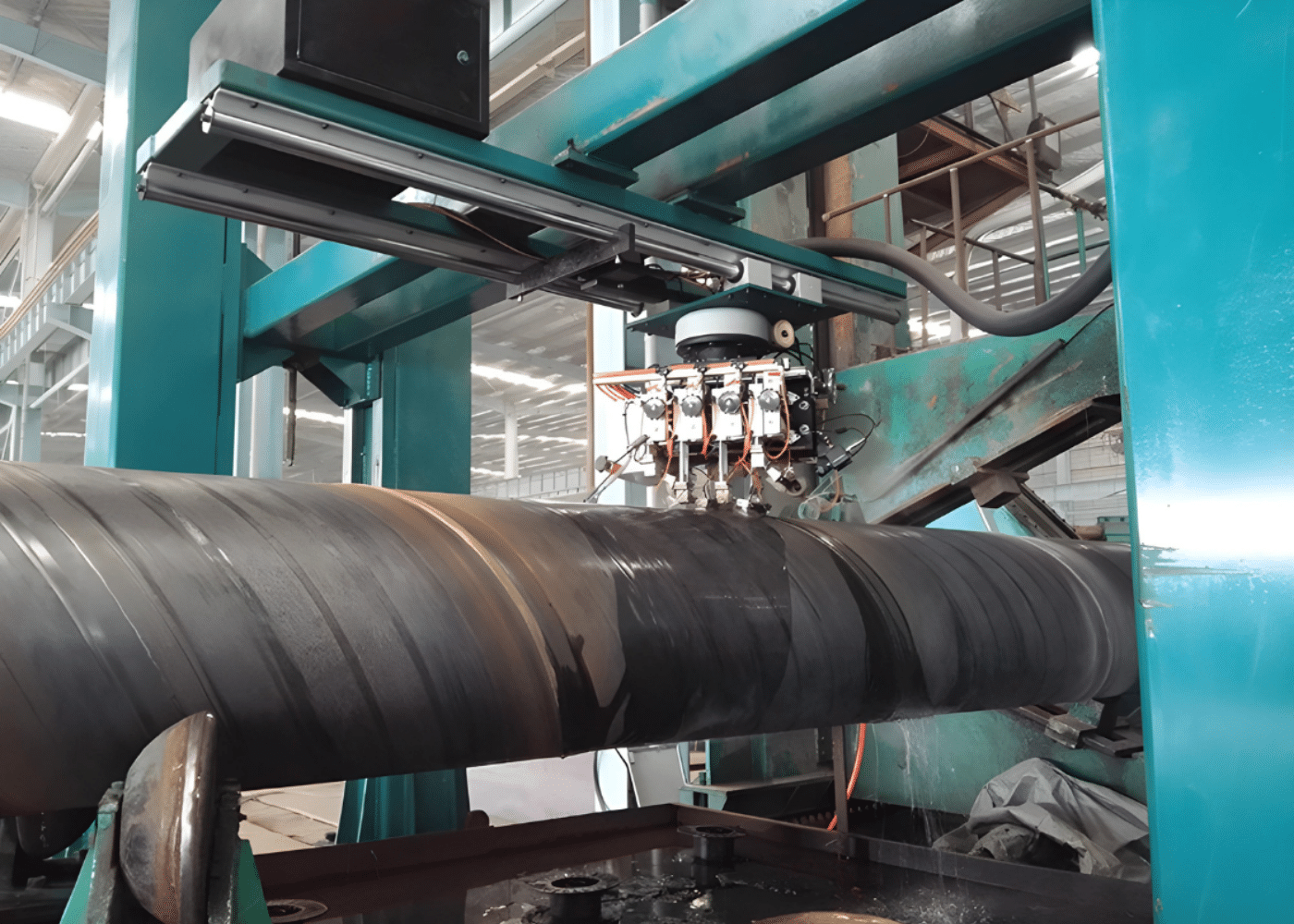

Spiral Submerged Arc Welded Steel Pipes (SSAW):

What are SSAW Pipes and How Are They Made?

Spiral Submerged Arc Welded (SSAW) pipes are manufactured by spirally forming steel plates or coils into a cylindrical shape, followed by continuous submerged arc welding along the helical seam.

This process enables the production of large-diameter pipes with excellent flexibility in wall thickness and length, making Spiral welded steel pipes ideal for water and wastewater systems, oil and gas pipelines, and structural applications.

Unlike seamless or longitudinal welded pipes, SSAW production is highly efficient for large-scale manufacturing — offering long pipe lengths, low material waste, and consistent weld quality.

Typical Sizes and Technical Specifications of SSAW Pipes

|

Parameter |

Range |

|---|---|

|

Outside Diameter (OD) |

219 mm – 3200 mm |

|

Wall Thickness (WT) |

5 mm – 30 mm |

|

Length |

3 m – 70 m |

|

Steel Grades |

EN 10219 / EN 10217: S235JR, S275JR, S355JR, S355J2H |

|

Standards |

EN 10219 / EN 10217, ASTM A252, API 5L PSL1/PSL2, BS 5950 |

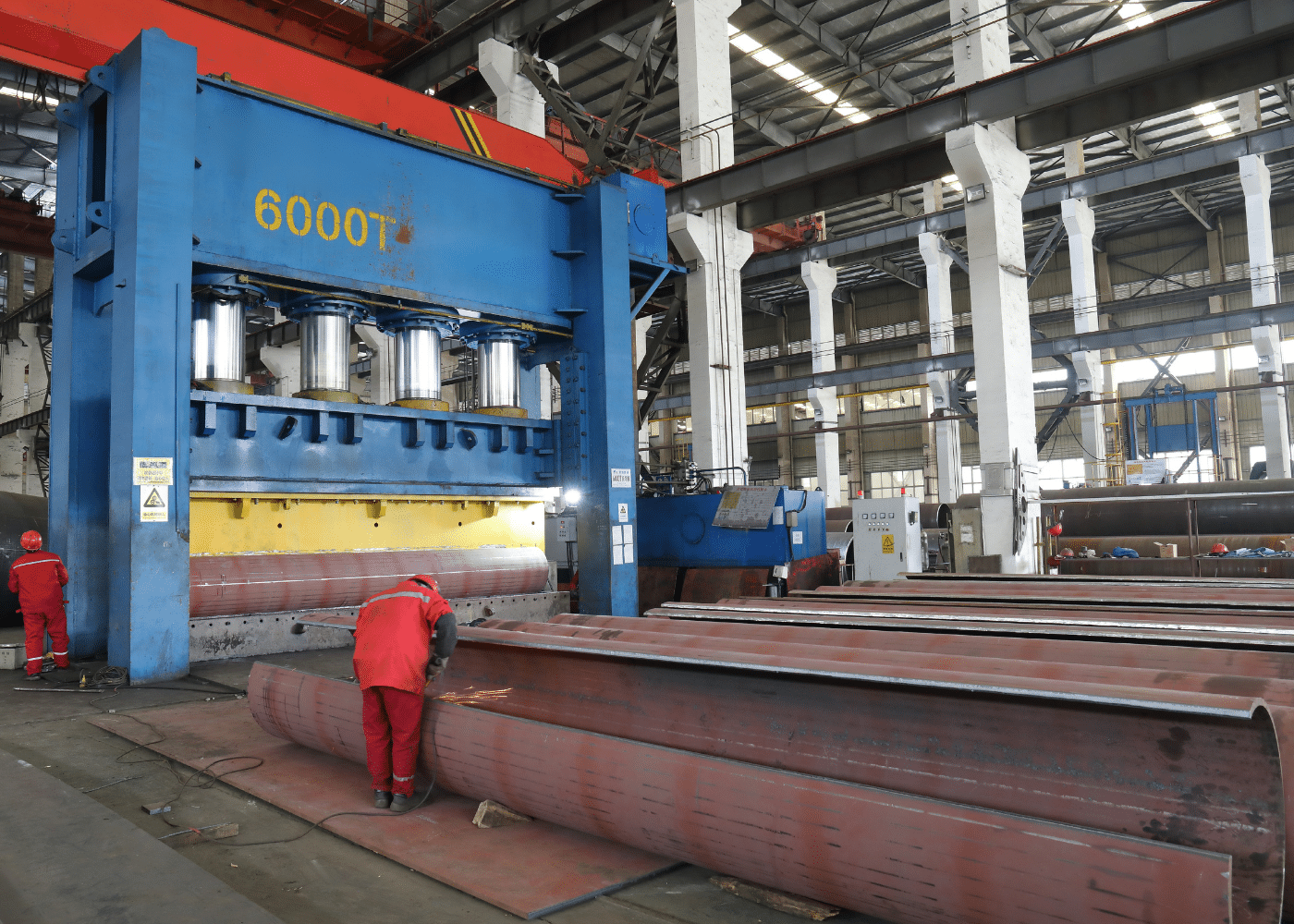

Longitudinal Submerged Arc Welded Steel Pipes (LSAW):

What Are LSAW Pipes and How Are They Made?

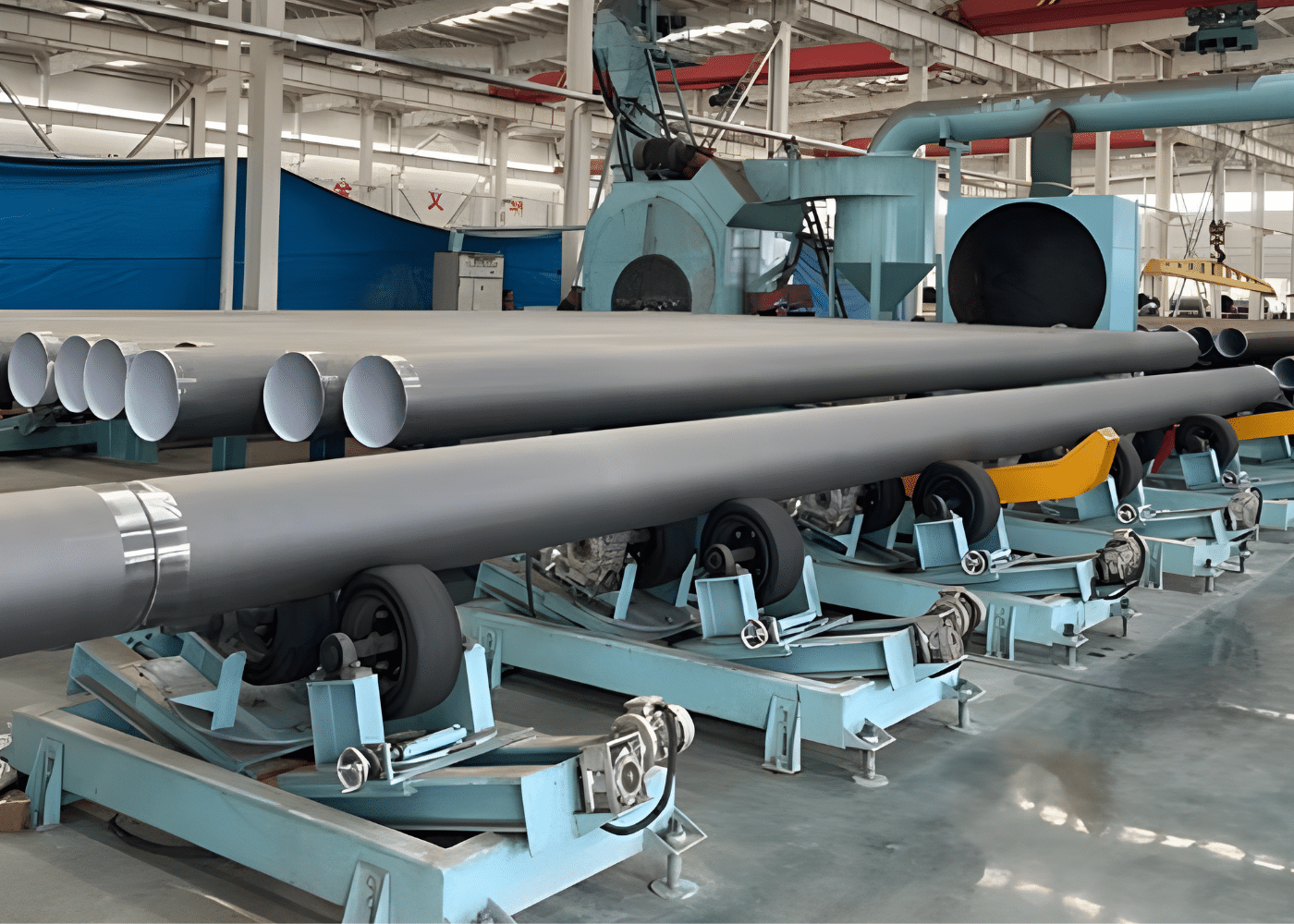

Longitudinal Submerged Arc Welded (LSAW) pipes are manufactured by bending steel plates into a cylindrical shape and welding them along the pipe’s longitudinal axis using the submerged arc welding (SAW) process. Double Submerged Arc Welded (DSAW) pipes are produced by welding inside and outside the seam.

This method ensures high dimensional accuracy, deep weld penetration, and excellent mechanical properties across the entire seam.

LSAW pipes are often chosen for applications requiring straight-seam precision, thick walls, and high structural reliability, such as offshore foundations, bridge piles, and heavy-duty pipeline systems.

Typical Sizes and Technical Specifications of LSAW Pipes

|

Parameter |

Range |

|---|---|

|

Outside Diameter (OD) |

355.6 mm – 5080 mm |

|

Wall Thickness (WT) |

6 mm – 120 mm |

|

Length |

3 m – 12 m |

|

Steel Grades |

EN 10219 / EN 10217: S235JR, S275JR, S355JR, S355J2H |

|

Standards |

EN 10219 / EN 10217, API 5L, ASTM A53, DIN 2458, GB/T 9711 |

|

Process |

LSAW – UO(UOE), RB(RBE), JCO(JCOE) |

Electric Resistance Welded Pipes (ERW):

What Are ERW Pipes and How Are They Made?

Electric Resistance Welded (ERW) pipes are produced by forming steel coils into cylindrical shapes and welding the seam through high-frequency electrical resistance.

The heat generated by the electric current fuses the edges without the use of filler material, producing a clean, uniform longitudinal weld.

ERW production is highly efficient, suitable for medium-diameter pipes that require tight dimensional tolerances and smooth internal surfaces.

Because of their cost-effectiveness and reliability, ERW pipes are widely used in construction, water and gas distribution, structural supports, and light piling applications.

Typical Sizes and Technical Specifications of ERW Pipes

|

Parameter |

Range |

|---|---|

|

Outside Diameter (OD) |

21.3 mm – 610 mm |

|

Wall Thickness (WT) |

1 mm – 25 mm |

|

Length |

0.3 m – 18 m |

|

Steel Grades |

EN 10219 / EN 10217: S235JR, S275JR, S355JR, S355J2H |

|

Standards |

EN 10219 / EN 10217, API 5L, API 5CT, ASTM A53, DIN 2458, JIS G3452, BS1387 |

What are welded pipes used for?

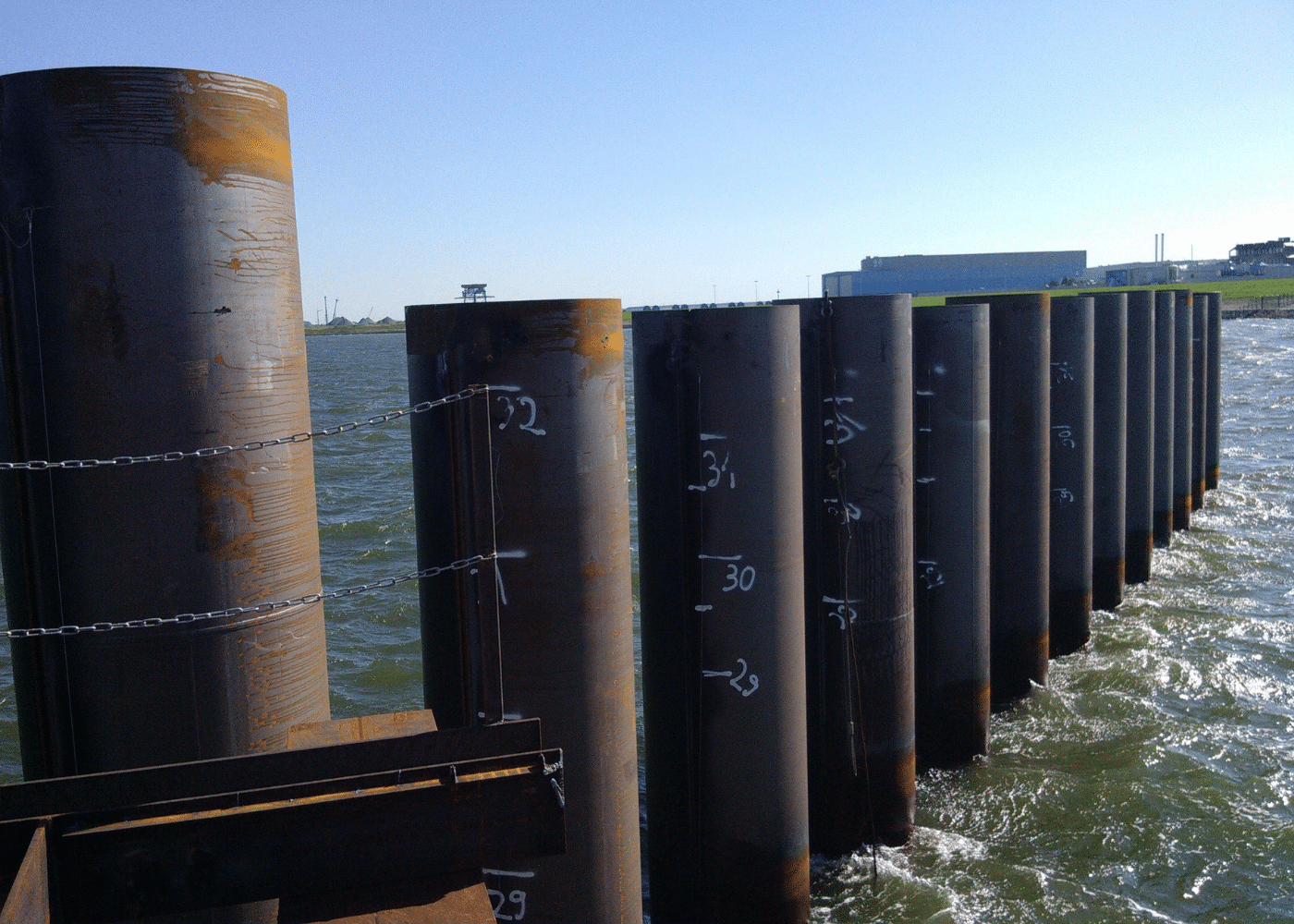

Welded pipes are highly versatile and widely used across infrastructure, industrial, and marine construction sectors, particularly where large diameters or long lengths are needed.

Typical applications include:

- Pipe piles for deep foundations and quay walls

- Combi wall systems (as king piles integrated with sheet piles)

- Water, oil, and gas pipelines

- Drainage and culvert systems

- Structural supports, frames, and casing

Because they can be produced in long lengths and large diameters, welded pipes are highly efficient for large-scale works such as harbor quay walls, offshore wind foundations, and bridge piling systems.

Are welded pipes weaker than seamless pipes?

A common misconception is that welded pipes are inherently weaker due to their weld seam. In reality, modern submerged arc welding (SAW) and high-frequency ERW techniques ensure uniform mechanical properties and weld strength equivalent to the base metal. Also, welded pipes are easier to inspect for quality assurance than seamless pipes.

For most piling, structural, and utility applications, welded pipes are the preferred solution due to their customisable dimensions, availability, and overall cost efficiency.

For piling, structural, and line applications, the difference in strength is negligible when both types meet international standards and proper NDT inspections are performed.

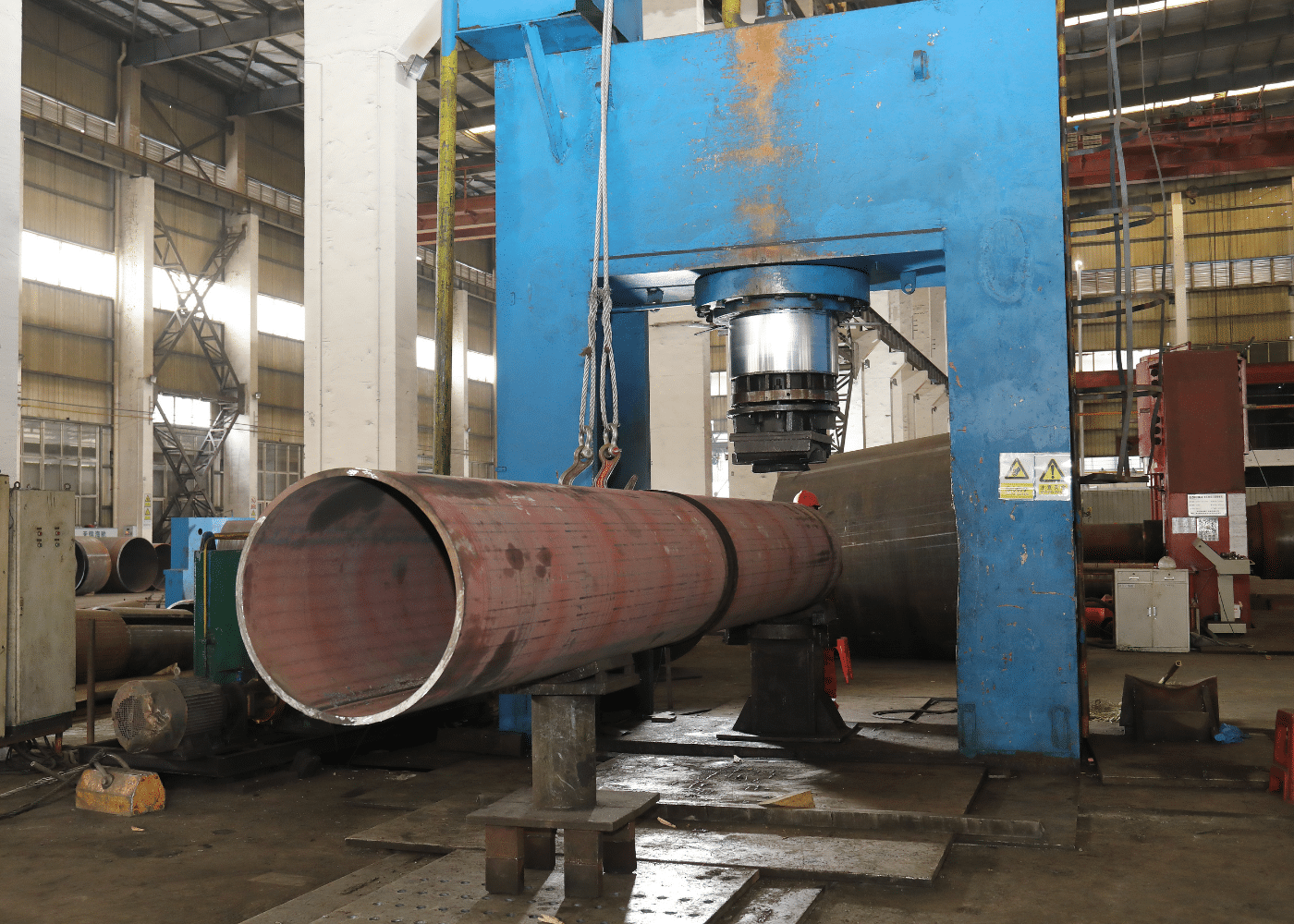

3. Casting Pipes (Specialised Steel Castings)

What are casting pipes and how are they made?

Casting is the least common manufacturing route for steel pipes and is generally reserved for short, specialised components rather than full-length pipeline or piling elements.

Casting pipes are primarily manufactured using the centrifugal casting process, in which molten steel is poured into a rotating cylindrical mould. Centrifugal force distributes molten steel evenly along the mould wall, producing a dense, defect-free structure with excellent mechanical integrity..

For short custom sections or special fittings, such as elbows or flanged ends, static mould casting methods — including sand or permanent moulds — may also be used. These techniques allow for complex geometries and thicker wall sections, though the resulting material typically has lower density than centrifugal cast pipes.

While this method provides high dimensional precision, it is far less economical than hot rolling or welding and therefore used only in niche applications requiring custom geometry, heat resistance, or wear performance beyond standard pipes.

What are the typical sizes of casting pipes?

- Outside diameter: 50 mm – 1500 mm

- Wall thickness: 4 mm – 50 mm

- Length: Typically up to 6–8 m

What are casting pipes used for?

Steel cast pipes and tubular components are mainly specified for:

- Process and power industries – heat-resistant tubes and reformer components.

- Hydraulic and dredging systems – thick-walled or abrasion-resistant liners.

- Industrial fittings – elbows, flanges, casings, or short custom pipe sections where casting simplifies fabrication.

They are not used for deep foundations or structural piling, where seamless or welded pipes provide better economics and mechanical properties.

Are casting pipes corrosion-resistant?

As with any carbon or low-alloy steel, corrosion resistance depends on the material composition and surface protection, not on the casting process.

Stainless or high-chrome alloy castings are preferred for aggressive environments, while carbon-steel castings typically require epoxy coatings, galvanisation, or claddings for durability.

Corrosion Resistance in Steel Pipes

Corrosion resistance depends mainly on steel composition, coating systems, and environmental exposure — not on whether a pipe is seamless, welded, or cast.

Carbon and low-alloy steels (such as S355 or API 5L) require protective coatings like epoxy, galvanisation (steel is coated with a layer of zinc to protect against corrosion), or polyurethane to ensure long-term durability in marine and underground environments. Carbon steel pipes are made from an alloy of iron and carbon. The carbon content in carbon steel pipes typically ranges from 0.2% to 2.1%.

Stainless steel and high-alloy grades (such as A312 TP316) naturally resist corrosion due to their chromium content, but are used mainly in chemical or offshore process systems where conditions exceed the limits of coated carbon steel.

- Stainless steel pipes are essential in industries where corrosion resistance is critical.

- Alloy steel pipes are made by combining steel with other elements to enhance specific properties.

With proper protection and regular inspection, steel pipes can achieve service lives exceeding 30 years, even in aggressive conditions.

Conclusion: Choosing the Right Steel Pipe for Your Project

Each steel pipe type serves a distinct purpose. Selecting the right steel pipe is crucial to ensure the efficiency and longevity of a project.

- Seamless pipes provide superior pressure resistance and uniform strength, ideal for critical and high-stress systems.

- Welded pipes offer unmatched flexibility in size, length, and cost efficiency, making them the foundation of modern infrastructure, piling, and marine projects.

- Casting pipes, though less common, remain vital for specialised industrial components requiring complex geometry and exceptional wear or heat resistance.

- Environmental and sustainability considerations are also important when selecting steel pipes for construction projects.

Ultimately, the right choice depends on your project’s structural demands, environmental exposure, and budget.

Related Products from Aema Steel

- Steel Pipe Piles

- Welded Seam Steel Pipes LSAW

- Spiral Welded Steel Pipes SSAW

- 2PE/3PE Anti-corrosion Pipes

- Anti-corrosion Pipes

- Combi Wall Systems

Contact us today to receive a tailored offer for your upcoming project.