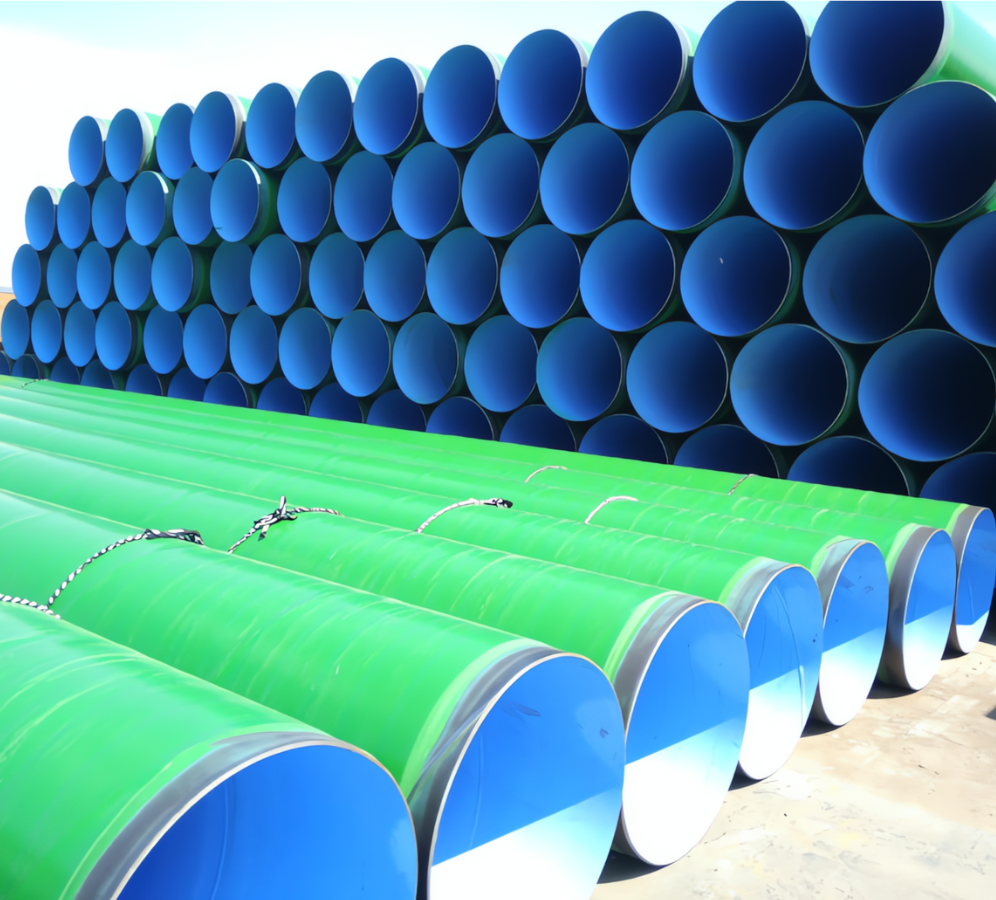

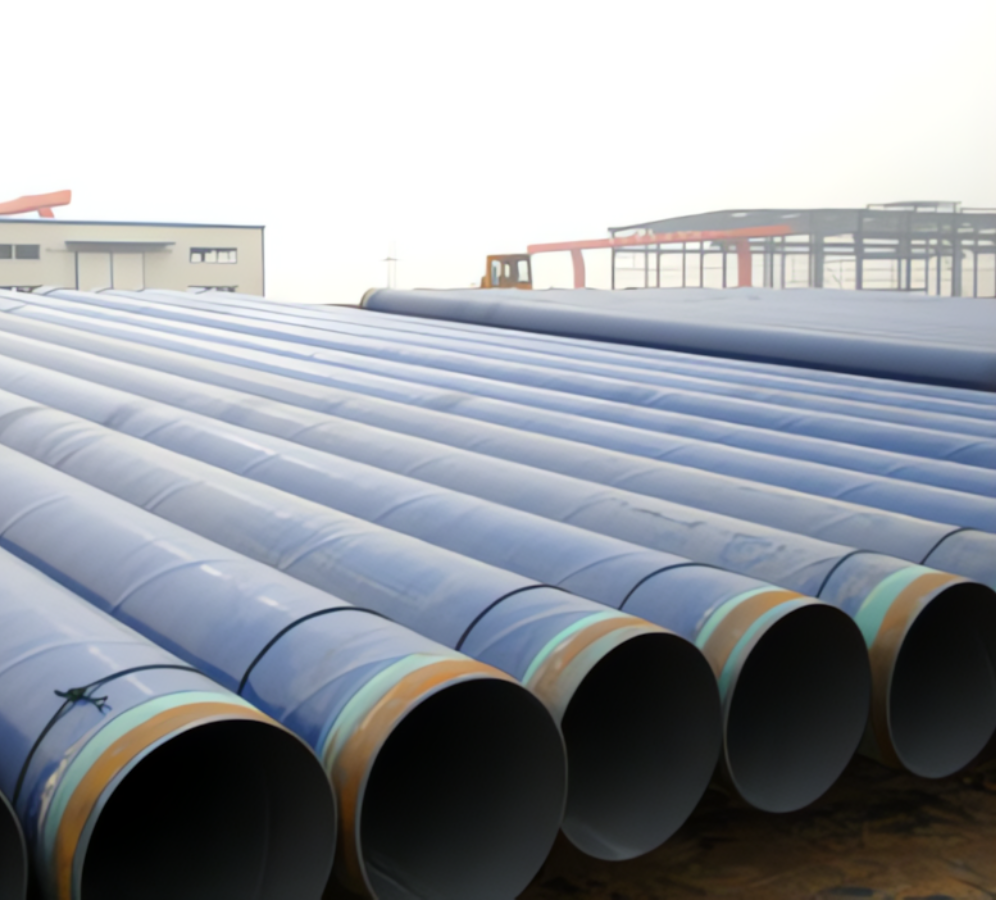

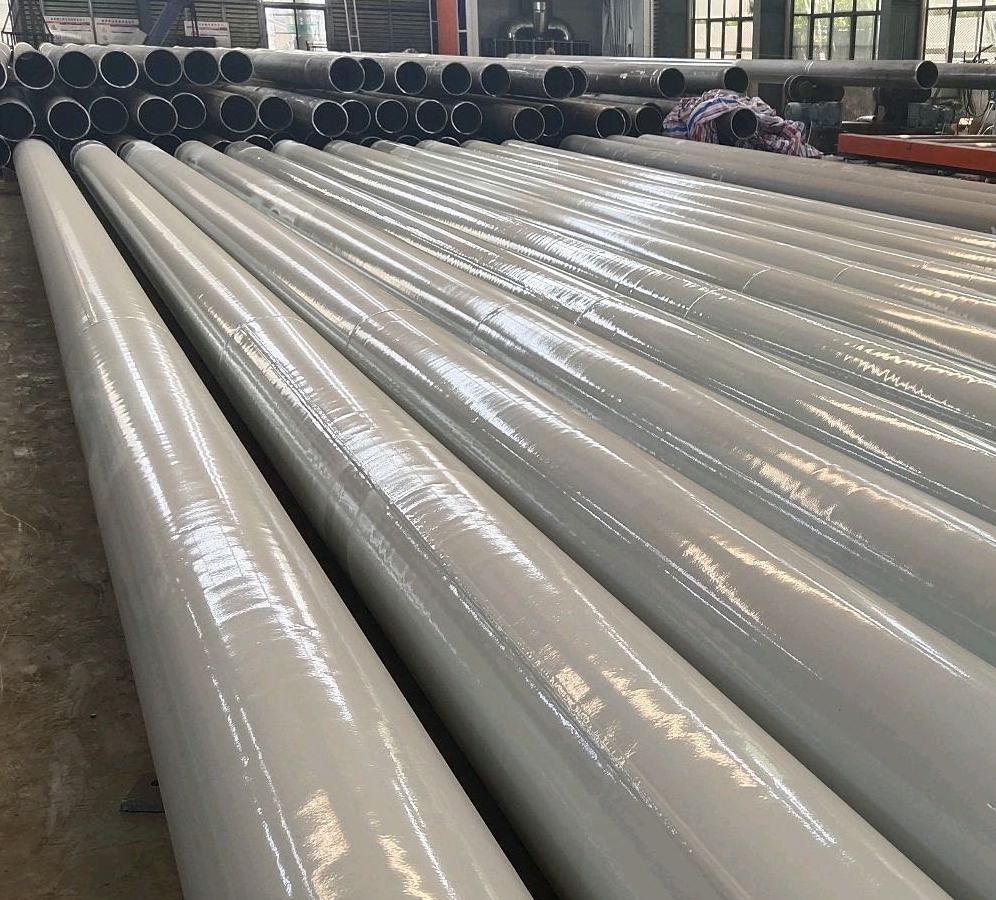

2PE/3PE Anti-corrosion Pipes

2PE/3PE anti-corrosion pipe coatings are advanced corrosion protection systems for steel pipes in harsh environments. These multilayer coatings effectively shield metal surfaces from oxidation, moisture, and salt spray, significantly extending the service life of pipeline components.

These anti-corrosion coatings form a durable barrier between the steel substrate and the environment, ensuring high corrosion resistance and excellent life expectancy even in temperatures up to 70°C. Available in various colours and thicknesses, the 2PE/3PE systems provide a flexible solution for diverse applications requiring added protection and long-term performance.

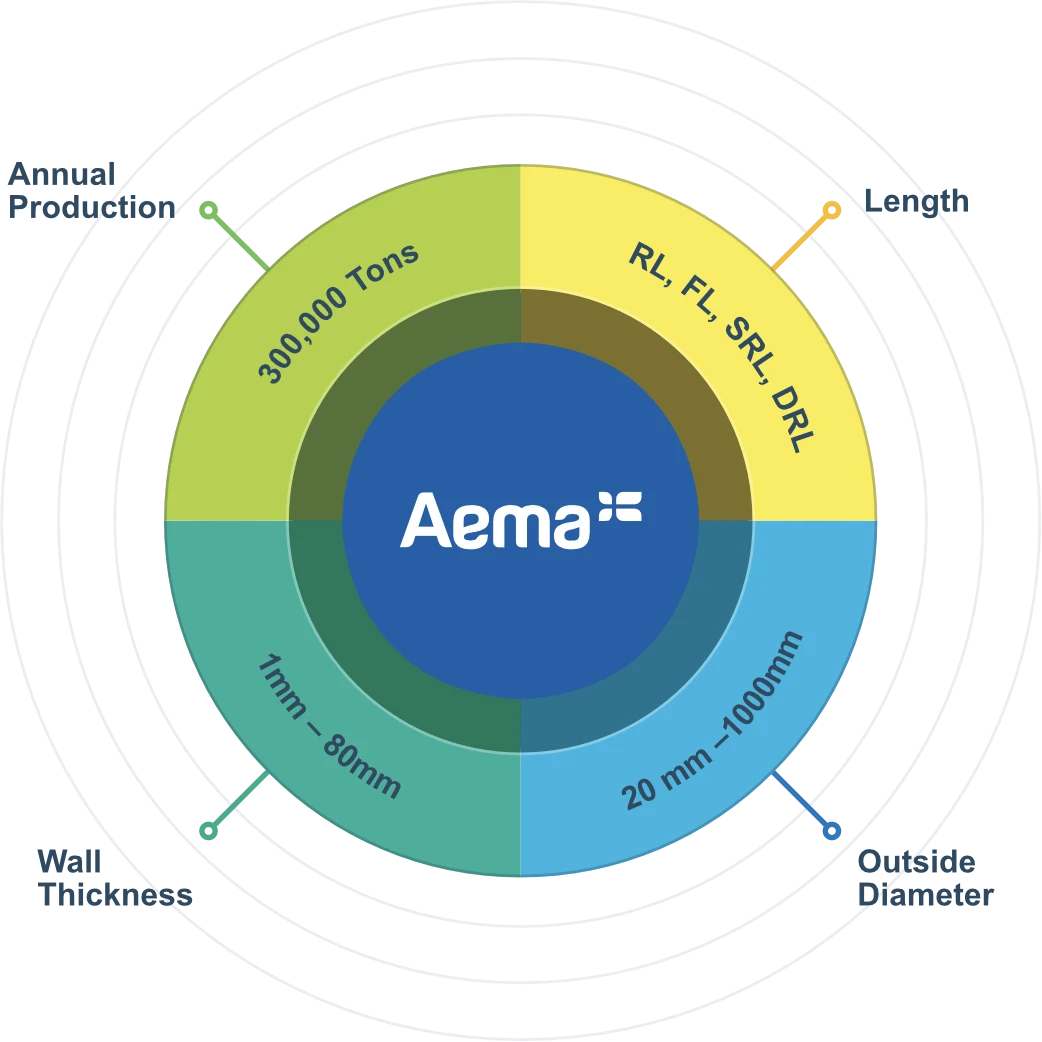

Outside Diameter: 20mm –1000mm

Wall Thickness: 1mm – 80mm

Length: RL, FL, SRL, DRL

Standard Compliance: API 5L / ASTM A53-2007 / ASTM A106-2006 / BS1139 / BS1387

Layer Breakdown of 2PE and 3PE Corrosion Protection Coatings

3PE Coating consists of:

- First layer: Fusion-bonded epoxy (FBE >80μm) provides strong adhesion and acts as a corrosion prevention barrier.

- Second layer: Adhesive (AD 170–250μm) – enhances bonding between FBE and the outer polyethylene layer.

- Third layer: Polyethylene (PE 1.8–3.7mm) – offers mechanical durability and long-term protection.

2PE Coating includes only the AD and PE layers, delivering effective corrosion resistance and mechanical protection where FBE is not required.

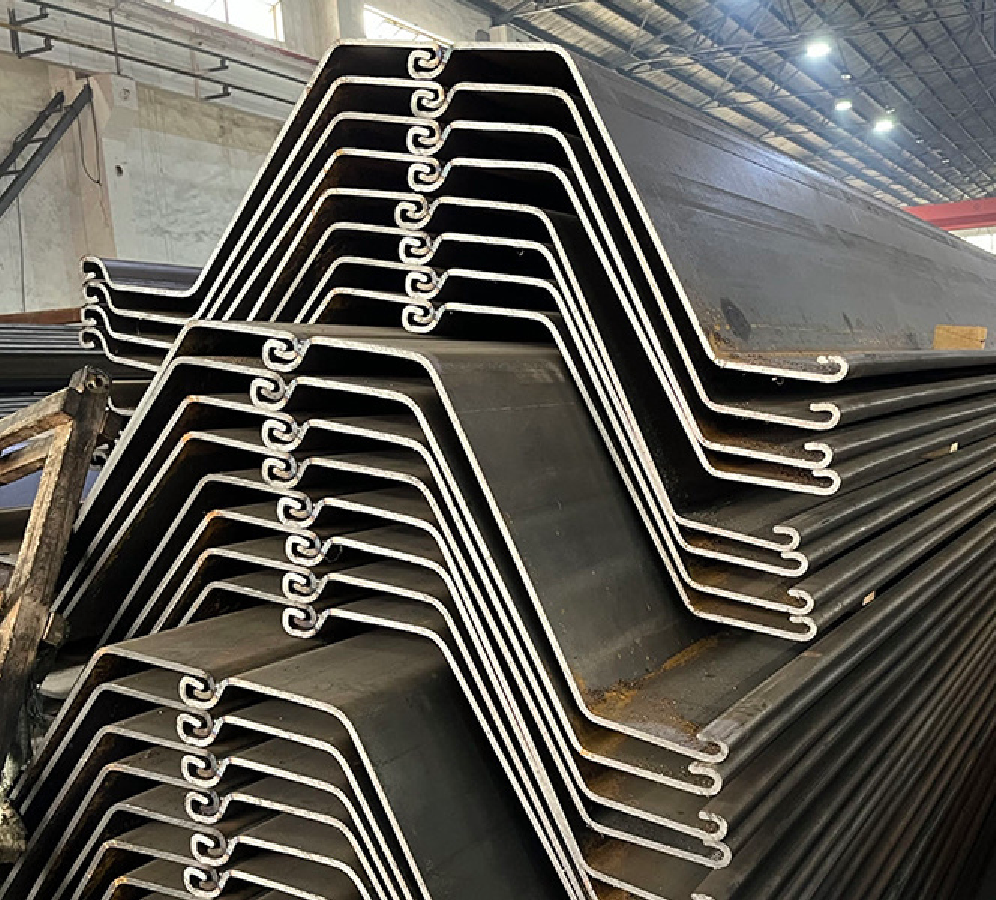

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.