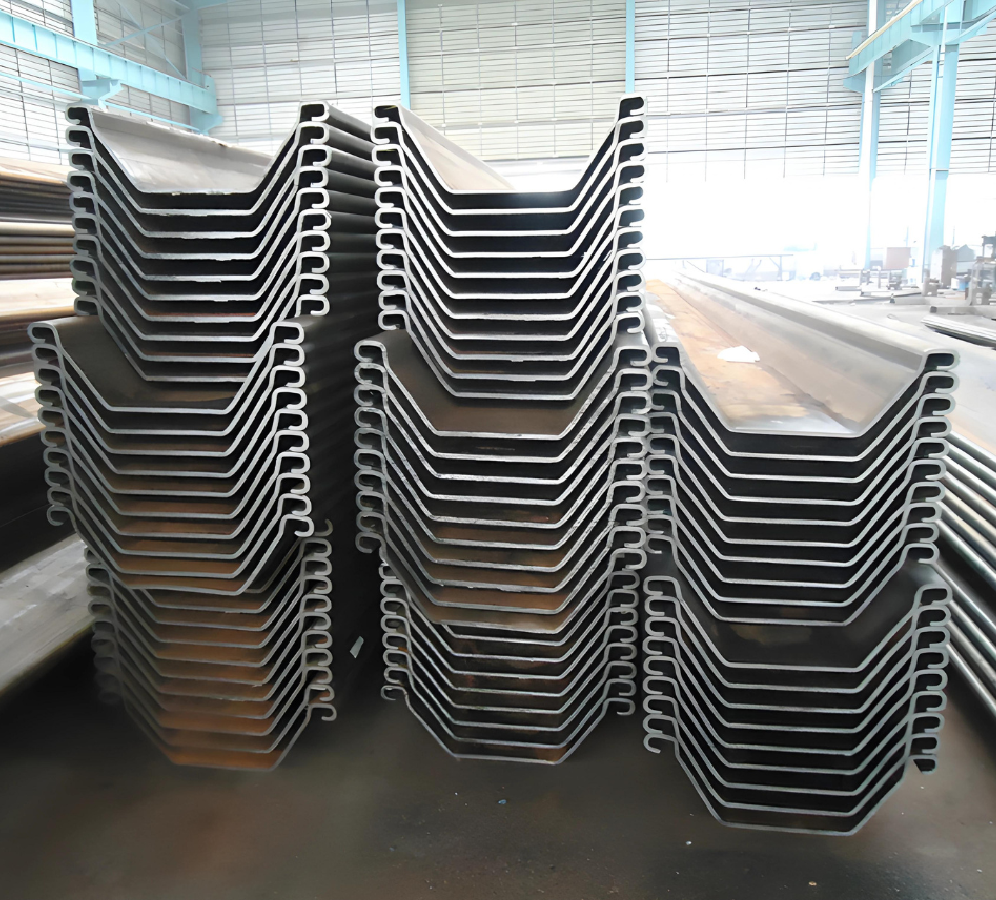

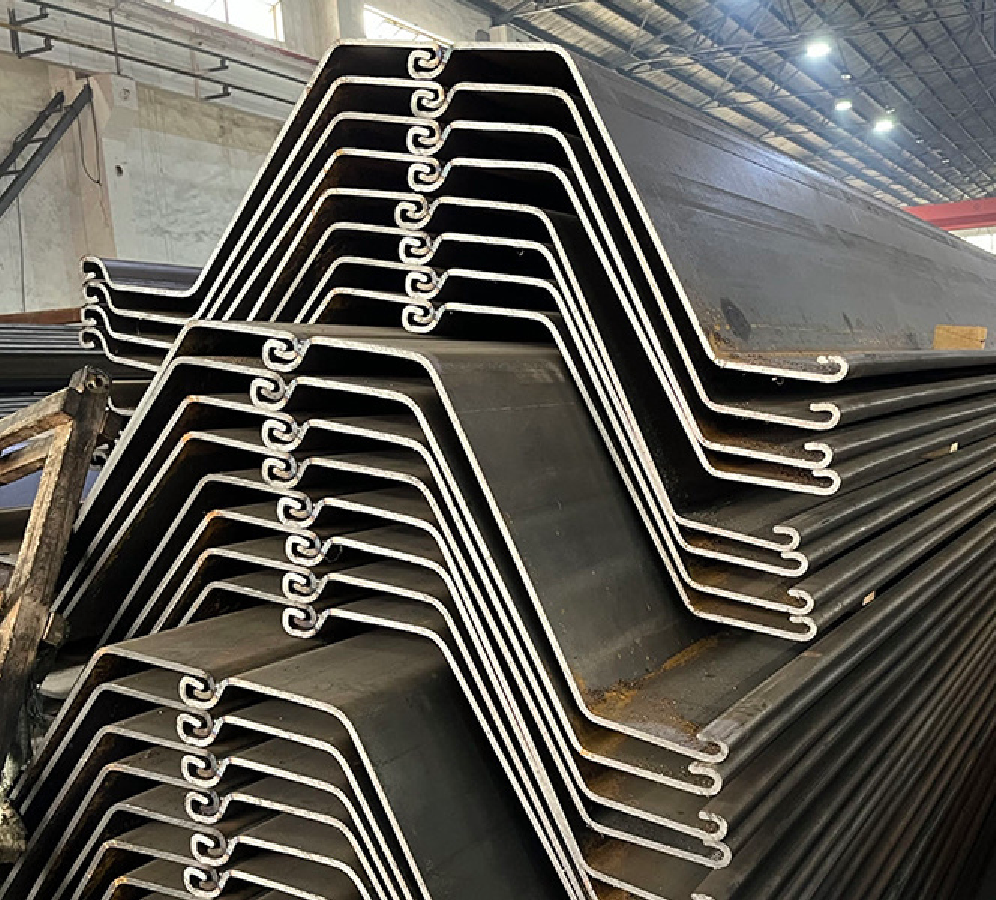

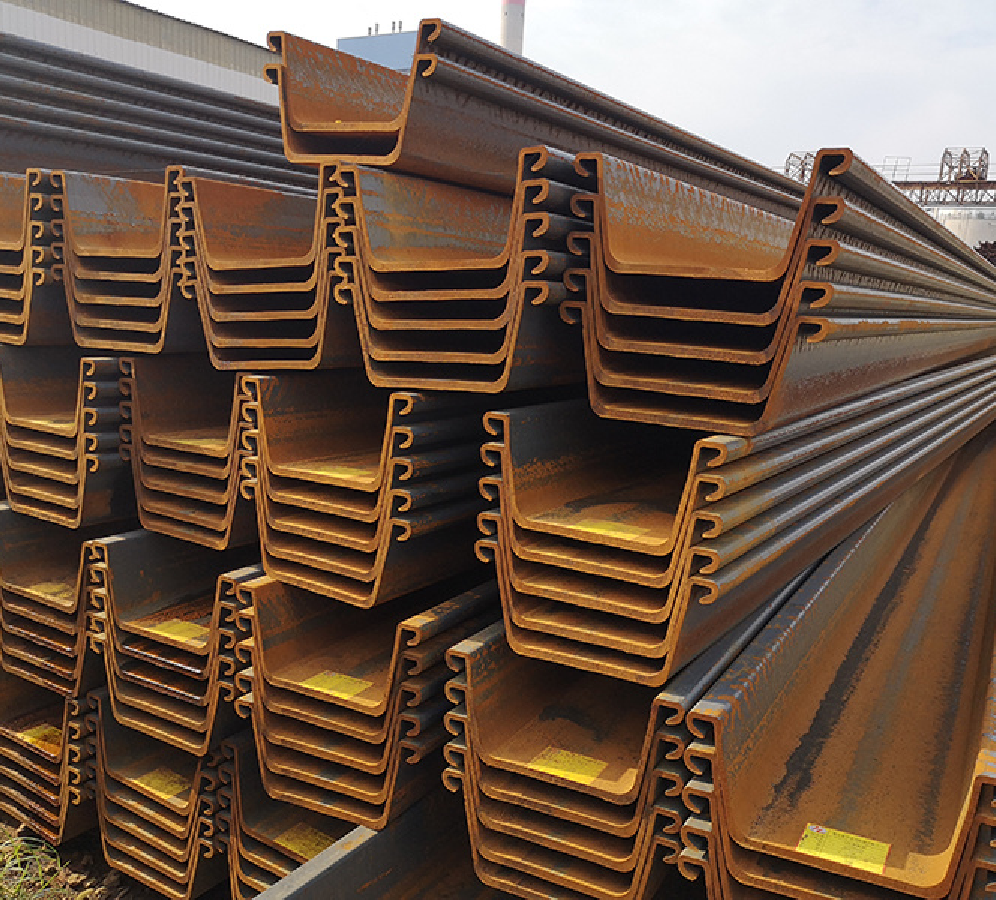

Cold-Formed U Type Sheet Piles

Cold-formed U-type sheet piles offer a reliable, cost-effective solution for infrastructure and foundation applications. Manufactured through a cold-forming process, cold-formed sheet piles provide enhanced mechanical strength and precision, making them ideal for projects where performance, flexibility, and budget efficiency are essential.

Cold-formed U-type steel sheet piles are suitable for both temporary and permanent installations. They are commonly used in retaining walls, reinforcing river and canal banks, and building temporary cofferdams. They are also effective in sewerage and drainage works, flood protection barriers, and curtain walling.

Advantages of Cold-Formed U Type Sheet Piles:

- High Bending Strength: Cold-formed U-type sheet piles have high bending resistance due to their uniform thickness and structural shape, making them suitable for deep wall construction and high-load environments.

- Cost-Efficient: The cold forming process optimises material use, reducing weight while maintaining structural integrity. This results in lower overall transportation, handling, and installation costs compared to traditional reinforced concrete walls.

- Custom Profiles and Lengths: We offer a wide range of U-profile sheet piles, including single, double, and box piles, with customisable lengths and thicknesses to meet specific project needs.

- Long-Term Performance: Cold rolled sheet piles are manufactured from high-quality steel grades and can be supplied with corrosion protection coatings to enhance durability and performance in permanent and temporary applications.

- Eco-Friendly: Lower emissions during the manufacturing process contribute to green construction.

Why Choose Our Cold-Formed U Type Sheet Piles?

- Fast production and a reliable supply chain.

- Competitive pricing without compromising quality.

- Customised profiles for temporary or permanent works.

- Full support from engineering consultation to on-site delivery.

Contact us today to receive a tailored offer for your upcoming project.

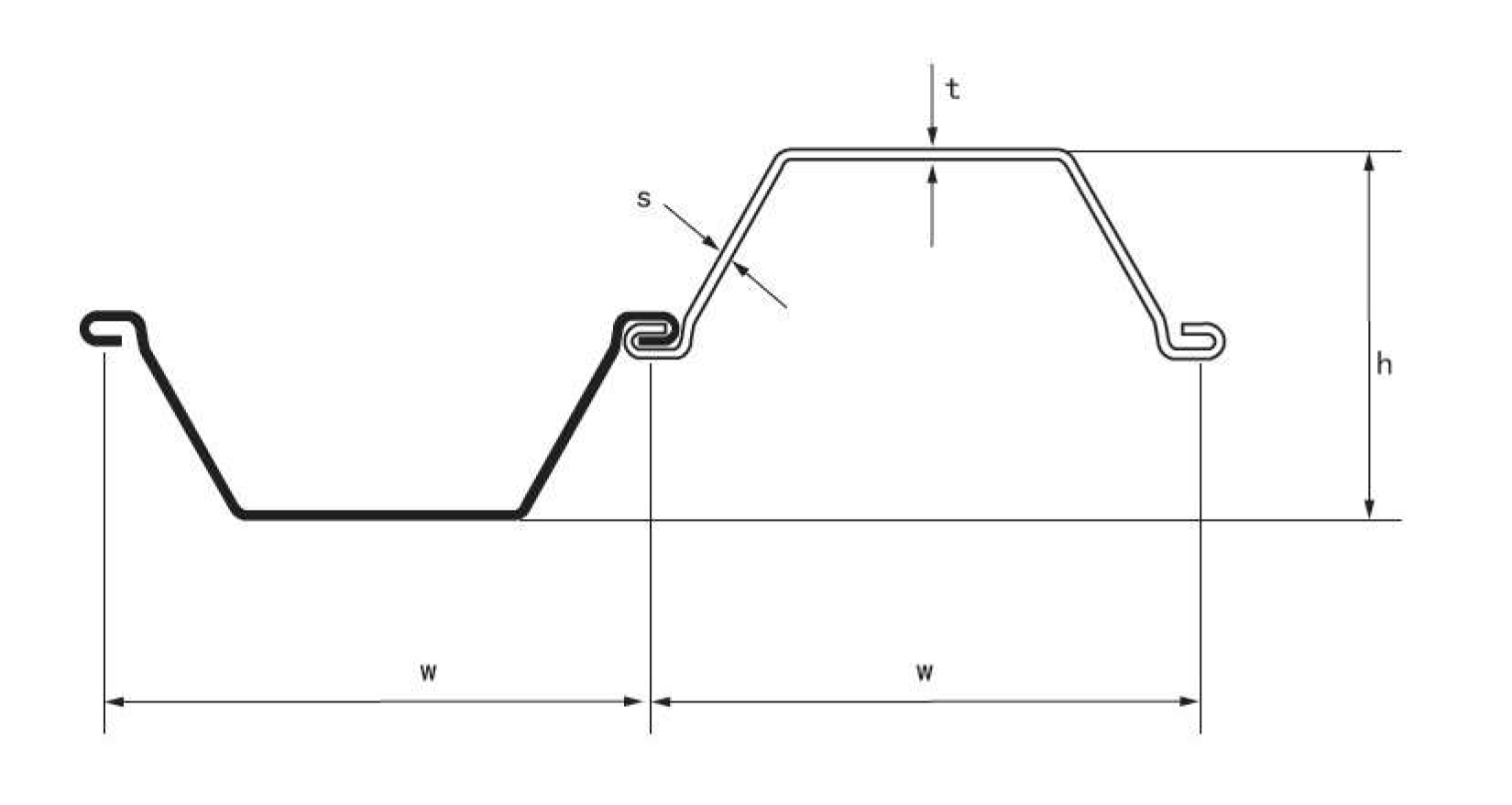

Specifications

| Section | Dimensions | Mass | Moment of inertia | Modulus of Section | ||||

| Width | Height | Thickness | Per pile | Wall | ||||

| w | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m² | cm⁴/m | cm³/m | |

| ZZU-5-2 | 600 | 150 | 9.5 | 9.5 | 63.9 | 106.5 | 4173 | 565 |

| ZZU-6-1 | 600 | 180 | 8.5 | 8.5 | 58.9 | 98.2 | 5475 | 617 |

| ZZU-6-2 | 600 | 280 | 6.0 | 6.0 | 42.2 | 70.3 | 9049 | 656 |

| ZZU-6-3 | 600 | 309 | 6.0 | 6.0 | 41.9 | 69.9 | 10016 | 658 |

| ZZU-7-1 | 600 | 300 | 6.0 | 6.0 | 43.7 | 72.9 | 10519 | 711 |

| ZZU-7-2 | 600 | 340 | 6.0 | 6.0 | 44.7 | 74.6 | 13284 | 791 |

| ZZU-7-3 | 600 | 310 | 6.4 | 6.4 | 44.1 | 73.5 | 10550 | 691 |

| ZZU-7-5 | 600 | 325 | 6.5 | 6.5 | 47.2 | 79.1 | 15551 | 782 |

| ZZU-8-1 | 600 | 360 | 6.0 | 6.0 | 45.2 | 75.4 | 14760 | 830 |

| ZZU-8-2 | 600 | 340 | 6.5 | 6.5 | 48.1 | 80.2 | 14899 | 886 |

| ZZU-8-3 | 600 | 325 | 7.0 | 7.0 | 51.8 | 86.3 | 14269 | 887 |

| ZZU-8-5 | 600 | 320 | 7.0 | 7.0 | 48.5 | 80.9 | 12349 | 781 |

| ZZU-8-6 | 600 | 325 | 7.3 | 7.3 | 50.8 | 84.6 | 13366 | 832 |

| ZZU-9-1 | 600 | 360 | 6.5 | 6.5 | 49.5 | 82.5 | 17371 | 975 |

| ZZU-9-3 | 750 | 320 | 7.0 | 7.0 | 59.9 | 79.9 | 14518 | 917 |

| ZZU-9-4 | 600 | 355 | 7.0 | 7.0 | 52.6 | 87.7 | 16834 | 958 |

| ZZU-10-1 | 600 | 300 | 7.0 | 7.0 | 53.9 | 89.8 | 19089 | 1042 |

| ZZU-11-2 | 600 | 360 | 8.0 | 8.0 | 62 | 103.3 | 20106 | 1126 |

| ZZU-12-1 | 600 | 380 | 8.5 | 8.5 | 66.1 | 110.2 | 22947 | 1217 |

| ZZU-12-2 | 500 | 360 | 8.0 | 8.0 | 56.5 | 113 | 20712 | 1217 |

| ZZU-12-3 | 700 | 440 | 7.5 | 7.5 | 64.2 | 90.9 | 26989 | 1236 |

| ZZU-12-4 | 600 | 360 | 9.0 | 9.0 | 69.6 | 116 | 22681 | 1270 |

| ZZU-12-6 | 600 | 360 | 8.5 | 8.5 | 66.1 | 110.2 | 21611 | 1211 |

| ZZU-27-1 | 600 | 500 | 11.5 | 11.5 | 108.6 | 181 | 67359 | 2704 |

| ZZU-27-2 | 600 | 420 | 15.0 | 15.0 | 139.8 | 233 | 57636 | 2756 |

| ZZU-28-1 | 600 | 500 | 12.0 | 12.0 | 115.3 | 192.2 | 70981 | 2851 |

| ZZU-28-2 | 600 | 480 | 13.0 | 13.0 | 124.9 | 208.1 | 67775 | 2834 |

| ZZU-28-3 | 600 | 460 | 10.2 | 10.2 | 97.4 | 162.3 | 75169 | 2694 |

| ZZU-28-4 | 600 | 565 | 10.5 | 10.5 | 101.8 | 169.6 | 80824 | 2871 |

| ZZU-30-1 | 500 | 500 | 13.0 | 13.0 | 117.6 | 235.2 | 75460 | 3029 |

| ZZU-32-1 | 600 | 525 | 13.0 | 13.0 | 130.0 | 216.7 | 84321 | 3222 |

| ZZU-32-2 | 600 | 515 | 14.0 | 14.0 | 138.4 | 230.7 | 82675 | 3222 |

| ZZU-32-3 | 750 | 645 | 11.0 | 11.0 | 122.2 | 162.9 | 112801 | 3197 |

| ZZU-32-4 | 700 | 560 | 12.0 | 12.0 | 129.5 | 185.0 | 90826 | 3256 |

| ZZU-32-5 | 670 | 520 | 14.0 | 14.0 | 144.8 | 216.2 | 82577 | 3186 |

| ZZU-32-6 | 600 | 595 | 11.2 | 11.2 | 109.9 | 183.2 | 91287 | 3079 |

| ZZU-32-7 | 600 | 600 | 11.5 | 11.5 | 114.1 | 190.2 | 96152 | 3215 |

| ZZU-32-8 | 600 | 605 | 11.8 | 11.8 | 118.4 | 197.3 | 102109 | 3386 |

| ZZU-35-1 | 700 | 560 | 13.0 | 13.0 | 143.6 | 205.1 | 97776 | 3503 |

| ZZU-35-2 | 750 | 608 | 12.0 | 12.0 | 136.1 | 181.5 | 105081 | 3467 |

| ZZU-37-1 | 750 | 610 | 13.0 | 13.0 | 151.0 | 201.3 | 114307 | 3757 |

| ZZU-40-1 | 750 | 610 | 14.0 | 14.0 | 163.9 | 218.5 | 122681 | 4032 |

| ZZU-40-2 | 700 | 580 | 15.0 | 15.0 | 167.4 | 239.1 | 115730 | 4001 |

| ZZU-43-1 | 750 | 610 | 15.0 | 15.0 | 177.0 | 236.0 | 132291 | 4349 |

| ZZU-43-2 | 750 | 615 | 16.0 | 16.0 | 186.4 | 248.5 | 133644 | 4356 |

| ZZU-46-1 | 750 | 630 | 16.0 | 16.0 | 192.5 | 256.7 | 145795 | 4639 |

Swipe

Note: The above specification is only a part of all the sizes, more sizes are available to suit specific project needs. Contact us for detailed information and customised solutions.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.