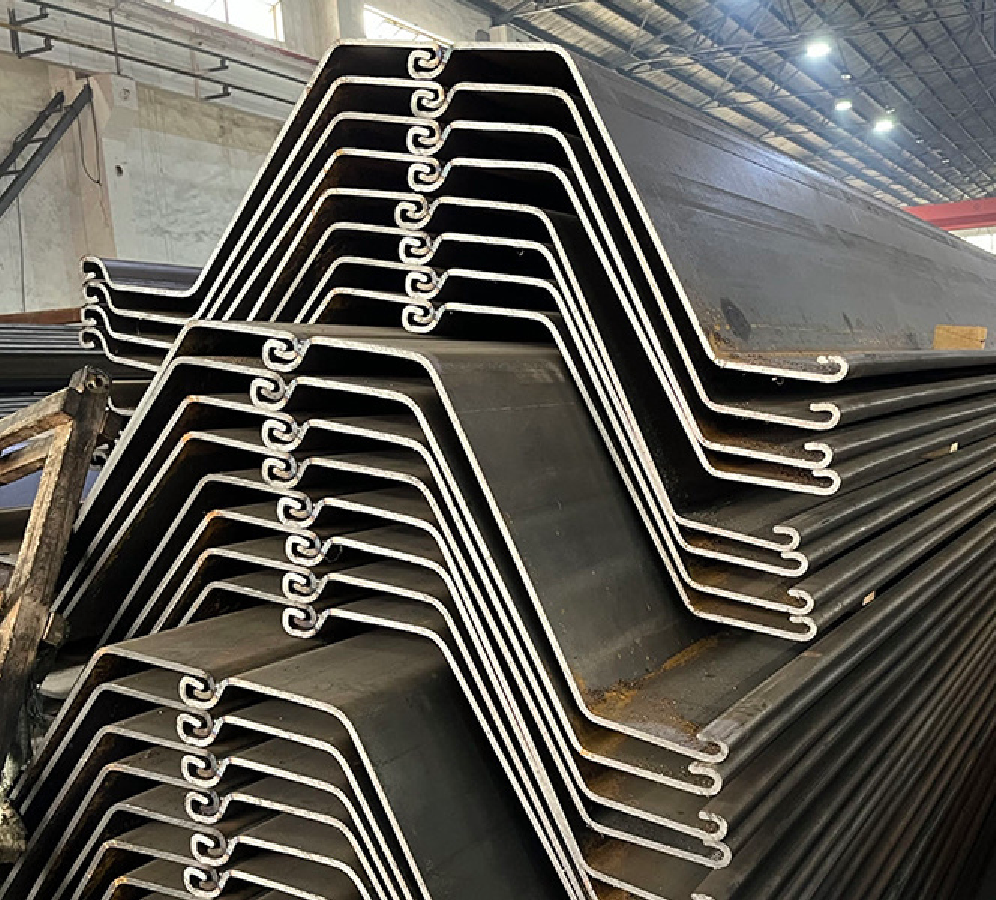

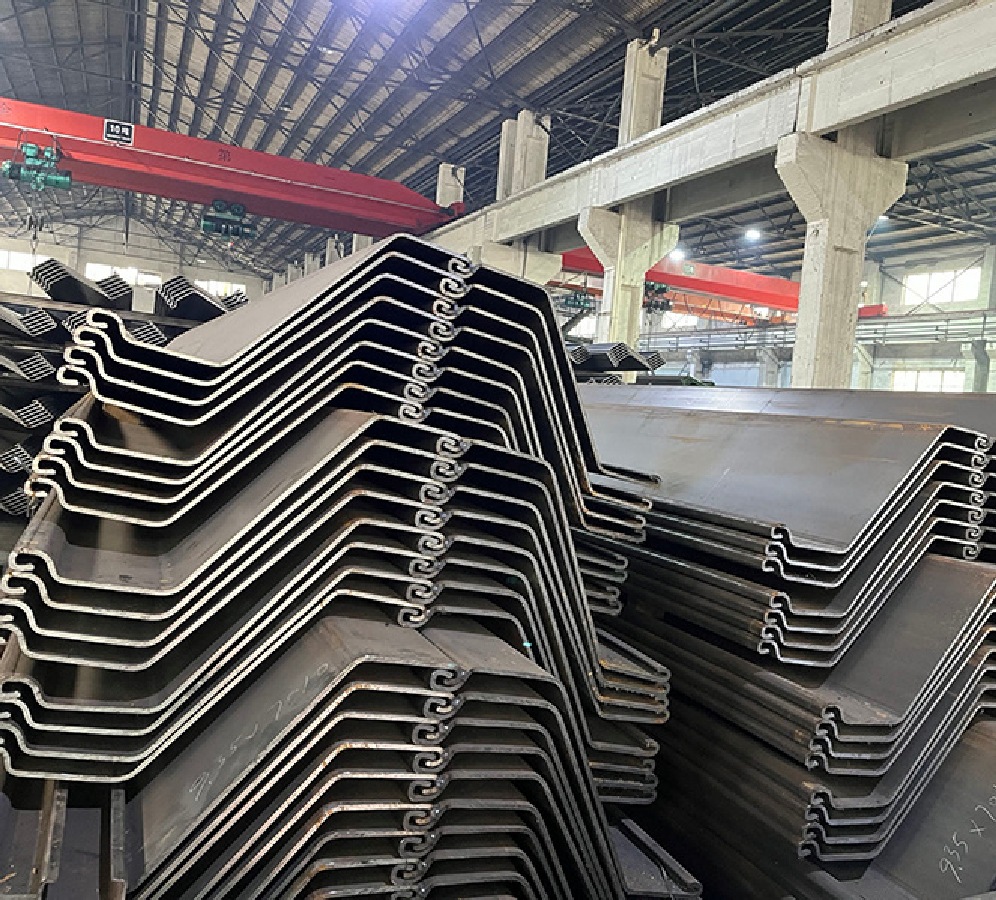

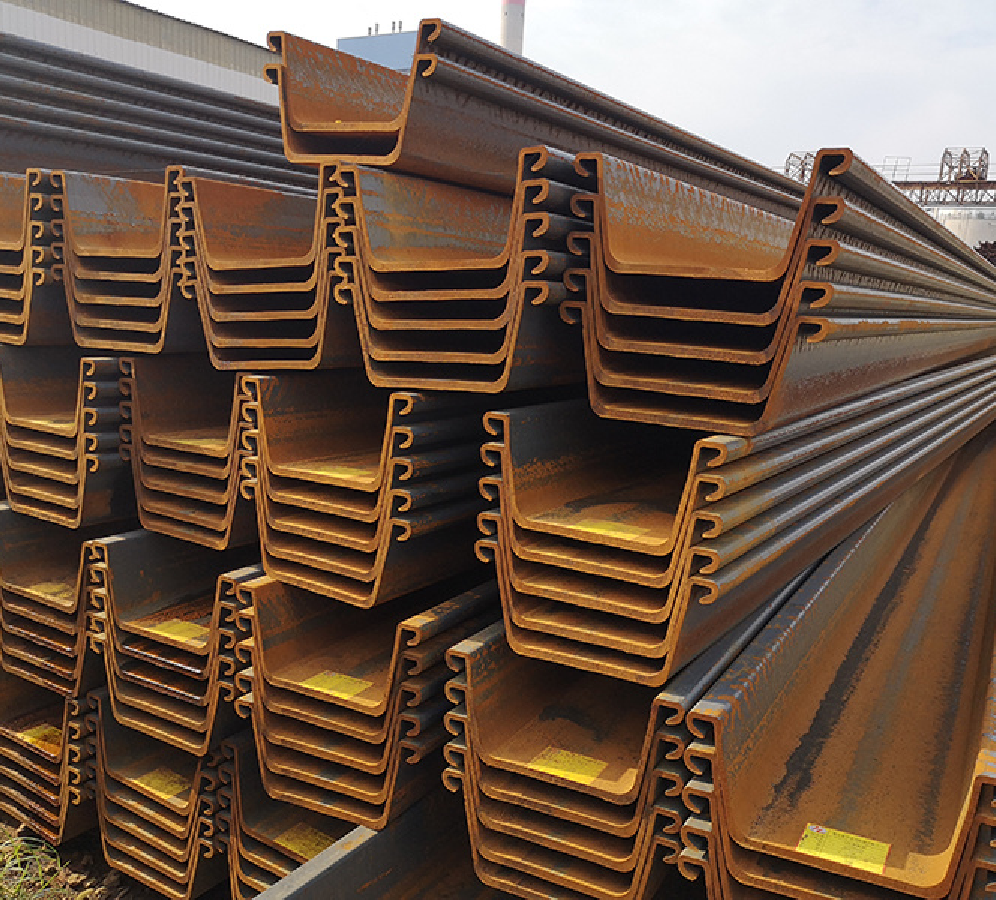

Cold Formed Z Type Sheet Piles

The large width of the sheet pile section allows for fewer interlocks per metre of wall, reducing installation time and overall project costs. Ideal for deep excavations, quay walls, flood protection, and canal reinforcement, Z-shaped sheet piles enhance water-tightness and offer a durable, high-performance solution for both temporary and permanent works across diverse soil conditions.

Advantages of Z-type cold-formed sheet piles:

- High Strength-to-Weight Ratio: The design of Z sheet piles maximises their section modulus and ensures structural integrity with less steel.

- Faster Installation: The wider profile of Z sections means fewer piles per wall length, reducing installation time and equipment requirements.

- Ideal for Deep Wall Construction: Z piles excel in applications involving deep excavation, harsh soil conditions, or high water pressure.

- Lightweight and Cost-Efficient: Due to the optimised geometry, cold-formed Z sections have a smaller weight without compromising stiffness, lowering transport, handling, and installation costs.

- Custom Profiles and Flexibility: Available in various widths, thicknesses, and lengths, with optional corrosion protection coatings and interlock sealants, tailored to your project requirements.

- Eco-Friendly: Lower emissions during the manufacturing process contribute to green construction.

Why Choose Our Cold-Formed Z Type Sheet Piles?

- Competitive pricing and fast production, without compromising quality.

- Flexible supply of custom dimensions and steel grades.

- Manufactured to meet global quality and performance standards.

- Supported by engineering and logistics expertise from request to delivery.

Contact us today to receive a tailored offer for your upcoming project.

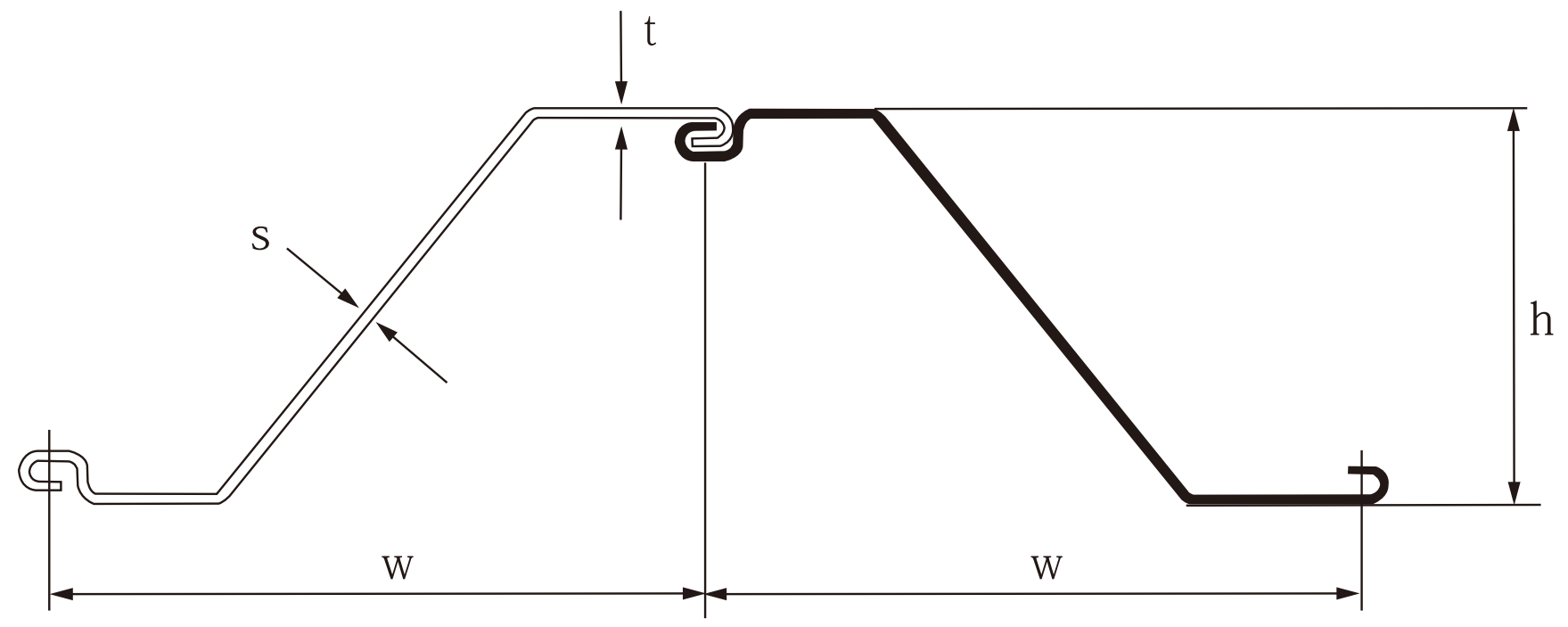

Specifications

| Section | Dimensions | Mass | Moment of inertia | Modulus of Section | ||||

| Width | Height | Thickness | Per pile | Wall | ||||

| w | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m² | cm⁴/m | cm³/m | |

| ZZZ-11-1 | 575 | 260 | 8.5 | 8.5 | 58.1 | 101 | 13871 | 1077 |

| ZZZ-11-2 | 575 | 260 | 9.5 | 9.5 | 63.2 | 109 | 14574 | 1131 |

| ZZZ-12-1 | 670 | 302 | 8.5 | 8.5 | 66.1 | 99 | 18737 | 1250 |

| ZZZ-12-2 | 770 | 344 | 8.5 | 8.5 | 72.6 | 94.2 | 22424 | 1313 |

| ZZZ-12-3 | 575 | 260 | 10.0 | 10.0 | 70.4 | 122.4 | 15856 | 1228 |

| ZZZ-12-4 | 700 | 314 | 8.5 | 8.5 | 67.4 | 96.3 | 18900 | 1213 |

| ZZZ-13-1 | 670 | 303 | 9.5 | 9.5 | 72.0 | 107.5 | 19392 | 1290 |

| ZZZ-13-2 | 770 | 344 | 9.0 | 9.0 | 75.6 | 98.1 | 22590 | 1323 |

| ZZZ-13-3 | 575 | 260 | 10.5 | 10.5 | 72.6 | 126.4 | 16551 | 1283 |

| ZZZ-13-5 | 700 | 316 | 10.0 | 10.0 | 77.2 | 110.2 | 20548 | 1314 |

| ZZZ-13-6 | 650 | 350 | 8.0 | 8.0 | 61.0 | 93.8 | 22810 | 1314 |

| ZZZ-14-1 | 670 | 304 | 10.5 | 10.5 | 80.8 | 120.6 | 21231 | 1406 |

| ZZZ-14-2 | 770 | 345 | 9.5 | 9.5 | 79.3 | 102.9 | 23407 | 1366 |

| ZZZ-14-3 | 770 | 345 | 10.0 | 10.0 | 82.9 | 107.7 | 24326 | 1420 |

| ZZZ-14-4 | 700 | 316 | 10.3 | 10.3 | 80.3 | 114.7 | 22269 | 1418 |

| ZZZ-15-1 | 700 | 420 | 7.0 | 7.0 | 60.0 | 85.7 | 31098 | 1491 |

| ZZZ-15-2 | 700 | 450 | 7.0 | 7.0 | 59.6 | 85.1 | 33214 | 1486 |

| ZZZ-16-1 | 575 | 350 | 8.5 | 8.5 | 63.9 | 111.2 | 28020 | 1611 |

| ZZZ-16-2 | 640 | 400 | 8.0 | 8.0 | 64.0 | 100.0 | 32432 | 1631 |

| ZZZ-17-1 | 630 | 379 | 8.5 | 8.5 | 67.8 | 107.6 | 31603 | 1677 |

| ZZZ-17-3 | 575 | 350 | 9.0 | 9.0 | 66.8 | 116.2 | 23051 | 1670 |

| ZZZ-17-4 | 575 | 370 | 9.0 | 9.0 | 67.0 | 116.5 | 31809 | 1729 |

| ZZZ-17-5 | 575 | 350 | 9.5 | 9.5 | 70.5 | 122.6 | 29807 | 1713 |

| ZZZ-17-6 | 675 | 430 | 8.5 | 8.5 | 70.5 | 104.4 | 36831 | 1723 |

| ZZZ-20-1 | 700 | 421 | 9.9 | 9.9 | 83.5 | 119.3 | 41042 | 1959 |

| ZZZ-21-1 | 575 | 350 | 11.0 | 11.0 | 85.4 | 148.5 | 36642 | 2104 |

| ZZZ-22-1 | 575 | 350 | 11.5 | 11.5 | 89.9 | 156.3 | 37924 | 2177 |

| ZZZ-23-1 | 575 | 350 | 12.0 | 12.0 | 94.1 | 163.6 | 39541 | 2269 |

| ZZZ-24-1 | 700 | 449 | 10.5 | 10.5 | 94.7 | 135.3 | 55267 | 2471 |

| ZZZ-24-2 | 575 | 350 | 12.5 | 12.5 | 99.1 | 172.3 | 41569 | 2385 |

| ZZZ-24-3 | 700 | 480 | 10.0 | 10.0 | 89.7 | 128.2 | 58923 | 2465 |

| ZZZ-24-4 | 700 | 540 | 9.5 | 9.5 | 86.1 | 123.0 | 66458 | 2471 |

| ZZZ-25-1 | 630 | 440 | 10.5 | 10.5 | 89.4 | 141.9 | 54761 | 2499 |

| ZZZ-25-2 | 675 | 440 | 11.0 | 11.0 | 97.2 | 144.0 | 55511 | 2533 |

| ZZZ-25-3 | 575 | 350 | 13.0 | 13.0 | 102.6 | 178.5 | 43470 | 2493 |

| ZZZ-26-1 | 630 | 470 | 11.5 | 11.5 | 97.8 | 155.2 | 63329 | 2706 |

| ZZZ-26-2 | 700 | 460 | 11.5 | 11.5 | 102.9 | 147.0 | 59898 | 2614 |

| ZZZ-26-3 | 675 | 430 | 12.0 | 12.0 | 105.5 | 156.3 | 56034 | 2616 |

| ZZZ-26-4 | 700 | 500 | 10.0 | 10.0 | 91.9 | 131.1 | 65333 | 2623 |

| ZZZ-26-5 | 700 | 470 | 10.5 | 10.5 | 96.9 | 138.4 | 62058 | 2651 |

| ZZZ-27-1 | 675 | 460 | 12.0 | 12.0 | 106.1 | 157.2 | 62347 | 2720 |

| ZZZ-27-2 | 630 | 480 | 10.5 | 10.5 | 91.5 | 145.2 | 65390 | 2734 |

| ZZZ-28-1 | 630 | 440 | 12.5 | 12.5 | 105.7 | 167.7 | 60632 | 2765 |

Swipe

Note: The above specification is only a part of all the sizes, more sizes are available to suit specific project needs. Contact us for detailed information and customised solutions.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.