Combi Wall Systems

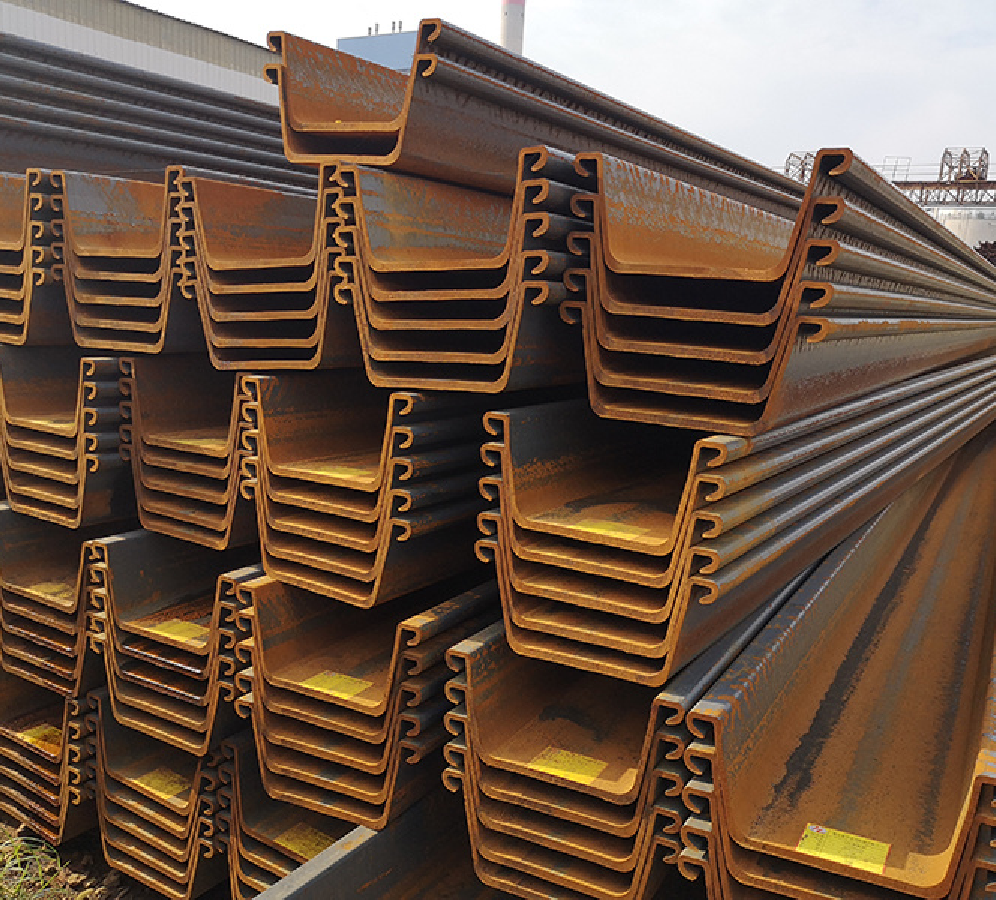

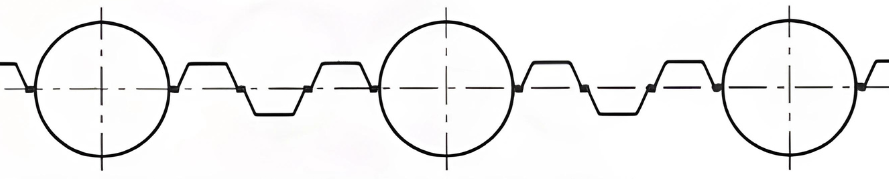

Combi walls, or combined wall systems, are advanced structural solutions that integrate steel pipe piles (tubular piles) with intermediate sheet piles to form a continuous wall system. This configuration is designed to carry substantial vertical loads and resist significant bending moments, making it suitable for both permanent and temporary applications in challenging soil and water conditions.

The main components of a combi wall system include:

- Steel pipe piles: Serve as the primary load-bearing elements, providing high load-bearing capacity.

- Intermediary sheet piles: Fill the gaps between bearing piles, retaining soil and water pressures and transferring loads to the king piles.

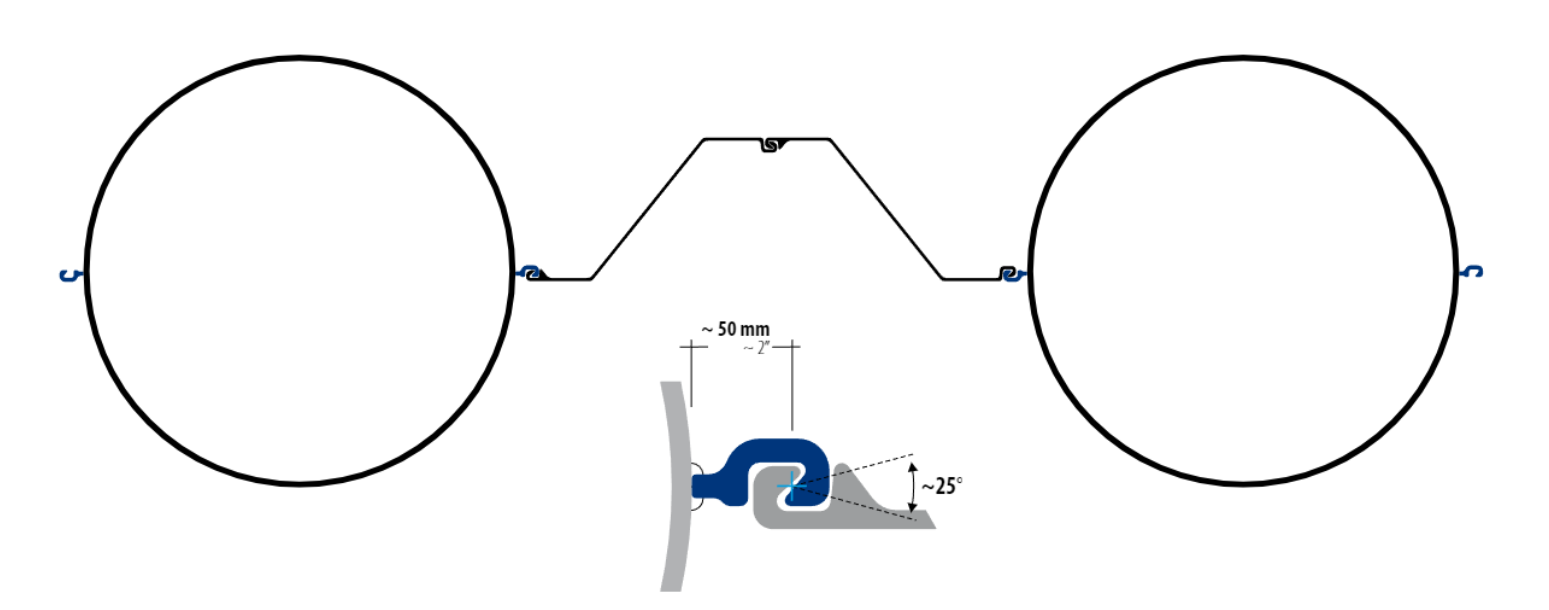

- Interlocks: Connect sheet piles to king piles, ensuring structural integrity.

This system is ideal for marine applications, such as quay walls, breakwaters, and cofferdams, where standard sheet-pile walls may not be sufficient.

Advantages of Combined Wall Systems:

- High Load-Bearing Capacity: The integration of king piles and sheet piles allows the system to carry substantial vertical loads and resist bending loads, making it ideal for heavy-duty applications.

- Versatility: Combi walls can be adapted to various soil conditions and water depths, providing flexibility in design and application.

- Ease of Installation: The use of vibratory hammers facilitates the efficient installation of both steel pipe piles and sheet piles, reducing construction time.

- Reusability: Components of the combi wall system can be reused in temporary applications, offering cost-effectiveness and sustainability.

- Enhanced Structural Integrity: The combination of pipe piles and sheet piles ensures a robust wall system capable of withstanding significant soil and water pressures.

Why Choose Our Combi Wall Systems?

- Tailored Engineering Support: We assist with recalculations and profile selection to match specific soil conditions, water pressure, and required loads, helping you reduce material weight and project costs.

- Full Range of Solutions: We supply all components for complete Combi Wall systems, including steel pipe piles, sheet piles, and clutches.

- High Load-Bearing Capacity: Our steel piles are carefully selected and configured to withstand substantial vertical and bending loads, ensuring structural stability even in the most demanding marine environments.

- Efficient Supply & Logistics: We streamline the procurement process, offering cost-effective delivery terms and reliable timelines across Europe.

- Custom Fabrication: We provide custom pipe dimensions, steel grades, welding of interlocks, and coating options, tailored to your project’s design and installation methods.

Contact us today to receive a tailored offer for your upcoming project.

Tubular Combi Wall with Double Z Sheet Piles

Tubular Combi Wall with Triple U Sheet Piles

Note: More arrangement types are available to suit specific project needs. Contact us for detailed information and customised solutions.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.