Hot Rolled Z Type Sheet Piles

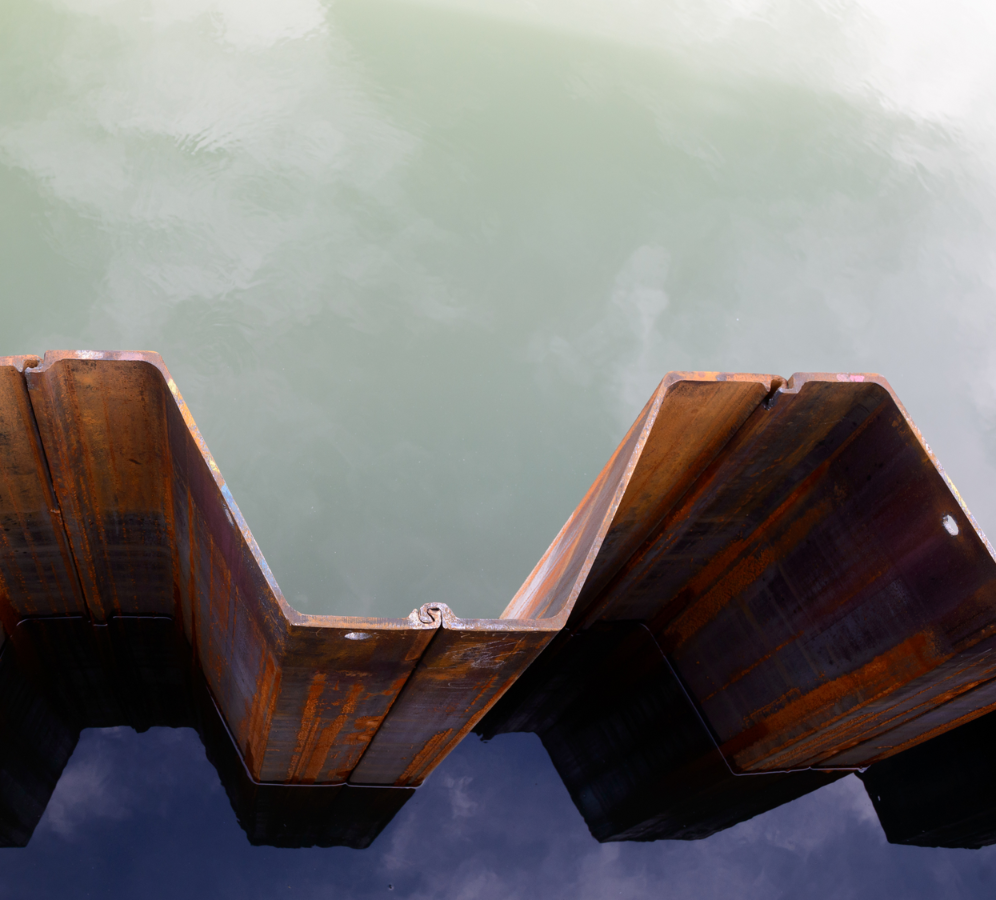

Hot-rolled Z-type Sheet Piles are high-performance steel profiles designed for deep excavation, permanent retaining structures, and marine engineering works. Formed through the hot rolling process, these Z-shaped sheet piles have interlocking edges located at the outer flanges of the profile. This design increases the section modulus and offers a superior strength-to-weight ratio.

Their wide sheet pile section reduces the number of interlocks per metre of wall, resulting in faster installation and cost-effective project execution. Hot-rolled Z-type sheet piles are especially suited for projects with high bending requirements, complex soil conditions, and water-retaining needs.

Advantages of Hot Rolled Z-Type Sheet Piles

- High Section Modulus: Interlocks positioned away from the neutral axis increase bending strength and stiffness with less material use.

- Efficient Installation: Wider profiles allow fewer sheet piles per wall, improving installation speed and reducing the required driving operations.

- Superior Water Tightness: Their interlocks help minimise groundwater inflow and are ideal for basement walls, flood protection, and waterfront structures.

- Excellent Durability: Hot rolling ensures consistent profile geometry, mechanical strength, and reliability in demanding soil and environmental conditions.

- Versatile Applications: Applicable in temporary and permanent works such as quay walls, bridge abutments, flood barriers, and foundation support.

Why Choose Our Hot-Rolled Z-Profile Steel Sheet Piles?

- Produced by trusted manufacturers with global supply capabilities.

- Technical consultation available for profile selection and design.

- Competitive pricing without compromising quality.

- Extensive product range for temporary or permanent works.

- Full support from engineering consultation to on-site delivery.

Contact us today to receive a tailored offer for your upcoming project.

Specifications

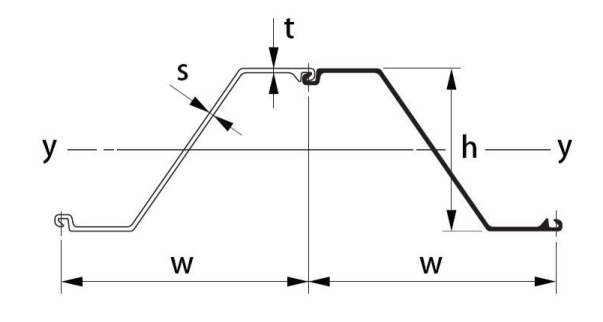

| Section | Dimensions | Mass | Moment of inertia | Modulus of Section | ||||

| Width | Height | Thickness | Per pile | Wall | ||||

| w | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m² | cm⁴/m | cm³/m | |

| ESZ 17-700 | 700 | 420 | 8.5 | 8.5 | 74 | 105.7 | 36360 | 1735 |

| ESZ 18-700 | 700 | 420 | 9.0 | 9.0 | 77.4 | 110.6 | 37890 | 1805 |

| ESZ 19-700 | 700 | 421 | 9.5 | 9.5 | 80.8 | 115.5 | 39420 | 1875 |

| ESZ 19-700 10/10 | 700 | 421 | 10.0 | 10.0 | 84.2 | 120.3 | 40940 | 1945 |

| ESZ 20-700 | 700 | 422 | 10.5 | 10.5 | 87.6 | 125.2 | 42470 | 2015 |

| ESZ 24-700 | 700 | 459 | 12.0 | 9.0 | 89.5 | 127.9 | 55870 | 2435 |

| ESZ 26-700 | 700 | 460 | 13.0 | 10.0 | 96.7 | 138.1 | 59810 | 2600 |

| ESZ 28-700 | 700 | 461 | 14.0 | 11.0 | 103.9 | 148.4 | 63750 | 2765 |

| ESZ 29-700 | 700 | 462 | 15.0 | 12.0 | 111.1 | 158.8 | 67740 | 2930 |

| ESZ 36-700 | 700 | 509 | 14.0 | 11.5 | 116.2 | 166.1 | 91130 | 3580 |

| ESZ 37-700 | 700 | 510 | 14.5 | 12.0 | 120.2 | 171.8 | 94000 | 3690 |

| ESZ 38-700 | 700 | 510 | 15.0 | 12.5 | 124.2 | 177.4 | 96860 | 3800 |

| ESZ 39-700 | 700 | 511 | 15.5 | 13.0 | 128.2 | 183.2 | 99720 | 3905 |

| ESZ 40-700 | 700 | 511 | 16.0 | 13.5 | 132.2 | 188.8 | 102590 | 4015 |

| ESZ 42-700 | 700 | 512 | 17.0 | 14.5 | 140.2 | 200.3 | 108360 | 4235 |

Swipe

Note: The above specification is only a part of all the sizes; more sizes are available upon request to suit specific project needs. Contact us for detailed information and customised solutions.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.