Marine Fenders

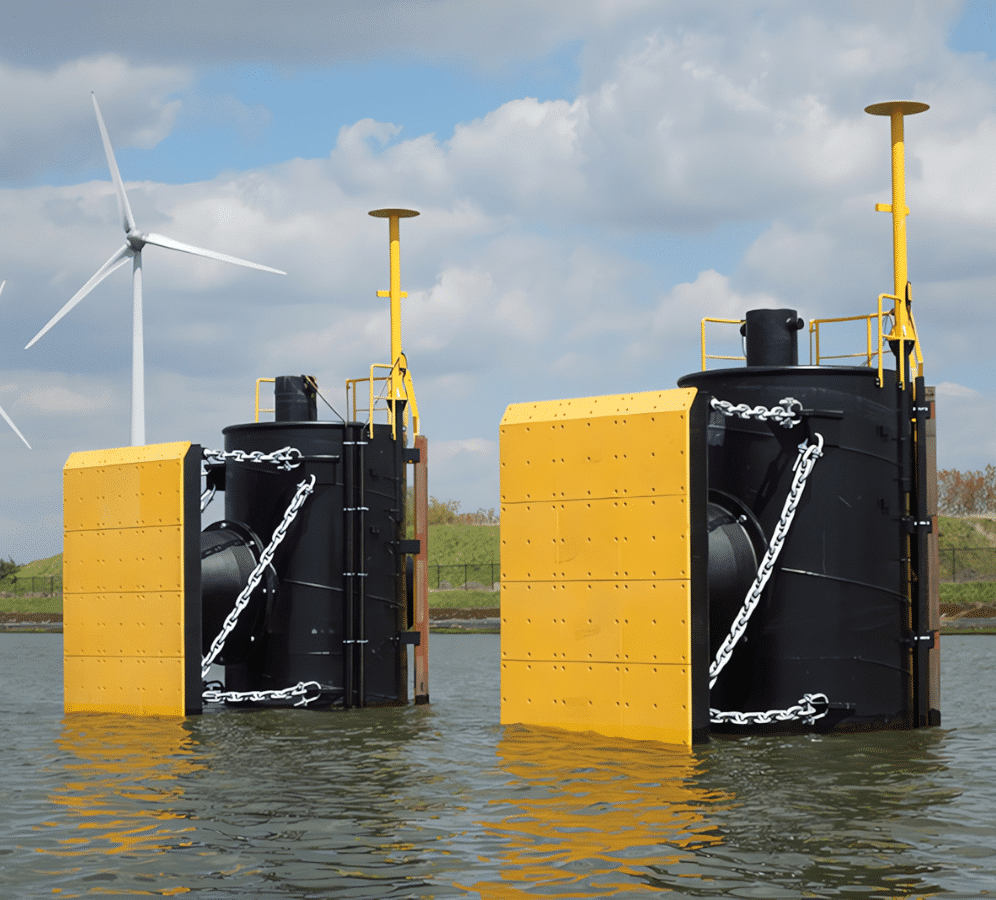

Aema Steel offers a wide range of high-quality marine fenders, engineered to absorb impact and protect both vessel hulls and dock structures during berthing operations. Manufactured from high-quality rubber and advanced composite materials, these fenders are built for durability, efficiency, and long service life in harsh marine environments. Whether for ports, harbours, offshore platforms, or marinas, our fender systems are designed to suit a wide range of applications, vessel sizes, and mooring conditions. The fenders we supply are PIANC type-approved and manufactured in accordance with PIANC guidelines for the design of the fender system (2002).

We supply a comprehensive range of solid as well as floating fender types—including cylindrical, arch, cone, cell, and pneumatic models—each selected to match specific energy absorption needs, mounting setups, and available installation space. Whether you’re outfitting a small boat dock or a large commercial harbour, we offer custom-manufactured fenders that fit your operational and environmental requirements.

Advantages of Marine Fenders:

- High Impact Absorption: Protects both vessels and docking infrastructure from collision damage.

- Reliable Performance: Engineered using robust rubber compounds for high energy absorption and low reaction force.

- Wide Product Range: Multiple types and sizes to suit berths, quays, jetties, and offshore platforms.

- Low Maintenance: Resistant to saltwater, UV rays, and mechanical wear.

- Custom Fit Solutions: Tailored fender systems with optional steel frontal frames and UHMW-PE pads.

- PIANC-Compliant Designs: Designed in accordance with PIANC guidelines to meet global best practices for port and marine safety.

Why Choose Our High-Quality Marine Fenders?

- Certified Quality: All fenders are manufactured according to international standards for safety and durability.

- Expert Support: Our team advises on fender selection, design layout, and performance calculations.

- Project-Specific Solutions: Fender systems are engineered and manufactured to meet the unique technical and environmental requirements of each project.

- Competitive Pricing: Cost-effective options that don’t compromise performance or longevity.

- Long-Term Value: Designed for durability and minimal maintenance, our fenders offer reliable performance and reduced lifecycle costs over time.

Contact us today to receive a tailored offer for your upcoming project.

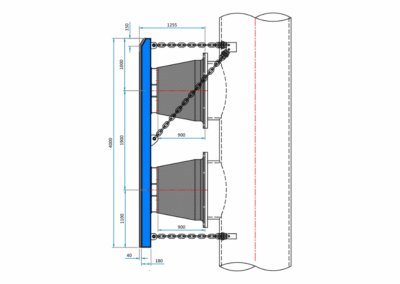

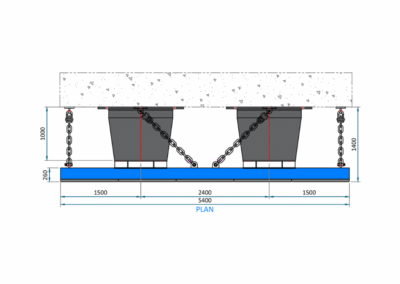

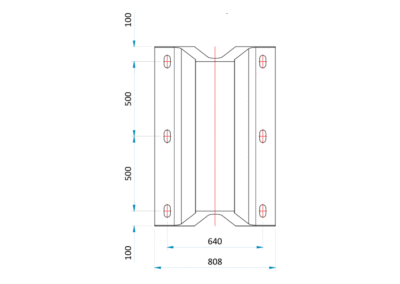

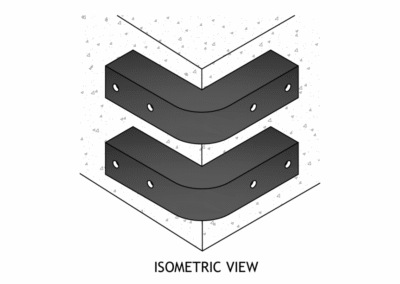

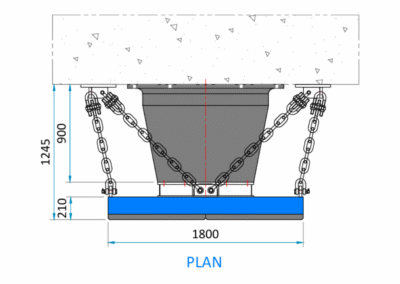

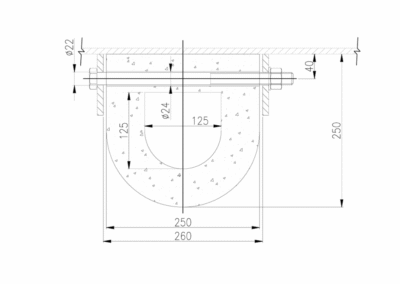

Marine Fenders Technical Drawings

Note: We supply a wide range of marine fender types, sizes, and energy absorption capacities to suit various berthing conditions and vessel types. Upon request, custom configurations and mounting arrangements can be provided to match your project’s technical and environmental requirements.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.