Mooring Bollards

Aema Steel supplies mooring bollards that ensure secure mooring operations in ports, harbours, quays, wharves, jetties, and offshore platforms. These marine bollards are manufactured from cast iron or steel and engineered using advanced finite element techniques to optimise geometry and anchor layouts for secure mooring performance. They can withstand full working loads across various vessel sizes and mooring line capacities.

We offer a comprehensive range of marine bollard types, suitable for different berthing conditions, vessel types, and installation constraints. With geometry and anchor layouts optimised for performance, each model is tailored to fulfill mooring requirements safely and efficiently. They are ideal for projects demanding high durability and reliable load transfer in harsh environmental and operational conditions.

Advantages of Mooring Bollards:

- Diverse Product Range: From horn bollards for tight berths to cleat bollards for lighter mooring duties, our product range covers diverse mooring applications.

- Supports Multiple Mooring Lines: Designed to accommodate varying mooring line angles and vessel sizes, ensuring reliable performance under different load conditions.

- Optimised Anchor Layouts: Customisable base and anchor configurations provide secure installation on concrete decks, quays, or wharves.

- Full Working Load Assurance: Each bollard is rated and tested to withstand its specified working load and mooring line capacity in real-world conditions.

- Suitable for diverse Marine Environments: Manufactured with corrosion-resistant materials and protective coatings for long-term use in saline and harsh weather environments.

- Compact & Efficient for Tight Installations: Space-saving designs and tailored geometry make them ideal for limited-space installations, warping operations, or smaller jetties.

Why Choose Our Mooring Bollards?

- Certified Marine-Grade Quality: Built to meet high standards for safety and longevity.

- Complete Range of Bollard Types: A diverse range of mooring bollards with various design profiles, sizes, and capacities ranging from 2 to 500 tons.

- Technical Expertise and Support: Guidance on anchor layout, bollard selection, and mooring design.

- Cost-Effective Installation: Simple and cost-effective to install, engineered to perform under demanding conditions.

Contact us today to receive a tailored offer for your upcoming project.

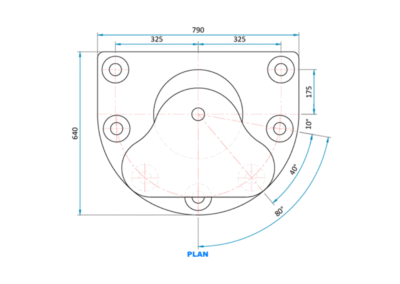

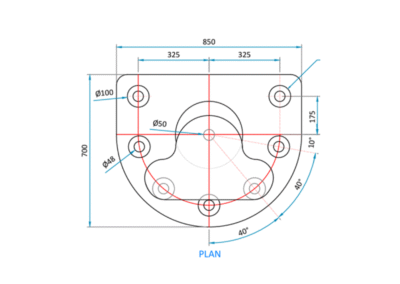

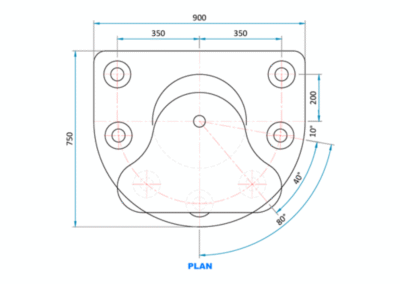

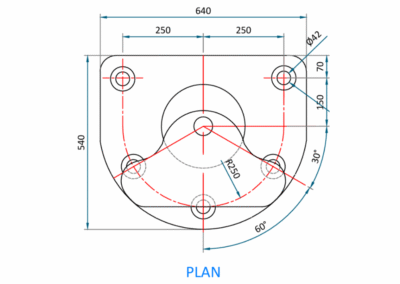

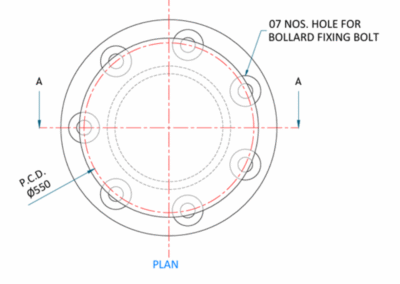

Mooring Bollards Technical Drawings

Note: We offer various bollard types and capacities to suit diverse port, harbour, and offshore requirements. Upon request, we can provide different types, sizes, and custom anchor layouts tailored to your project specifications.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.