Steel Tie Rod Systems for Marine Applications

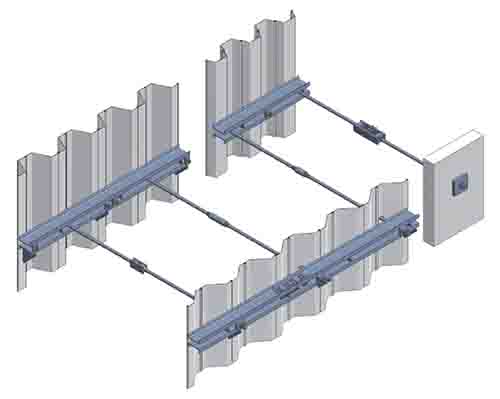

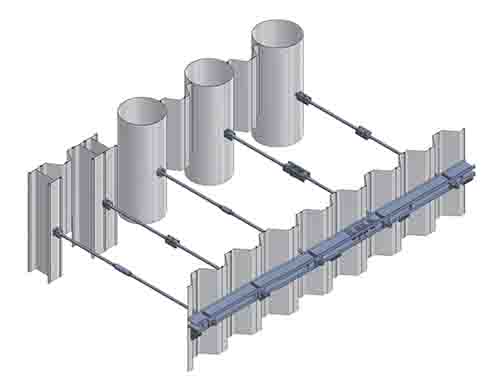

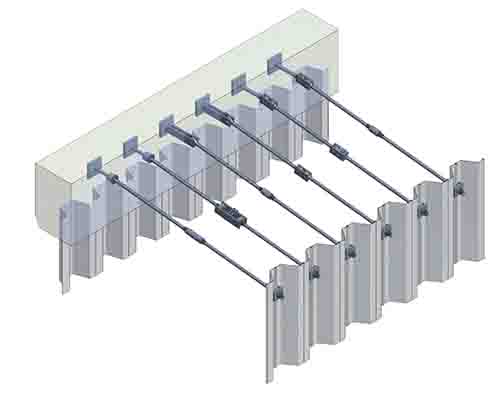

Steel tie rod systems are engineered to provide reliable tension and anchoring for quay walls, cofferdams, and other marine and civil engineering structures. Designed for high-strength performance, each system includes key components such as bars, upset threads, nuts, couplers, and spherical washers, ensuring flexibility and stability under compression and tension forces.

Available in standard and custom lengths, we supply steel tie rods in various diameters and steel grades to suit various loads and geometries and meet project-specific requirements. Whether used in combination with waling beams or as part of a larger anchor wall solution, our systems are tailored to withstand harsh environments and dynamic marine conditions.

Advantages of Steel Tie Rod Systems:

- High tensile strength and corrosion-resistant materials.

- Customisable lengths and diameters to suit various loads and geometries.

- Fully integrated tie rod systems including bolts, plates, couplers, nuts, and washers.

- Compatible with waling beams, sheet pile walls, combi walls and concrete walls.

- Upset threads for increased fatigue resistance.

- Quick and secure installation process

Why Choose Our High-Strength Marine Tie Rods?

- Full range of marine tie rods for ports, harbours, and offshore projects.

- Engineering support from the early stage of your project.

- Flexible manufacturing tailored to unique project requirements.

- Strict quality control of all components.

- We streamline the procurement process, offering cost-effective delivery terms and reliable timelines across Europe.

Contact us today to receive a tailored offer for your upcoming project.

Steel Tie Rod Applications

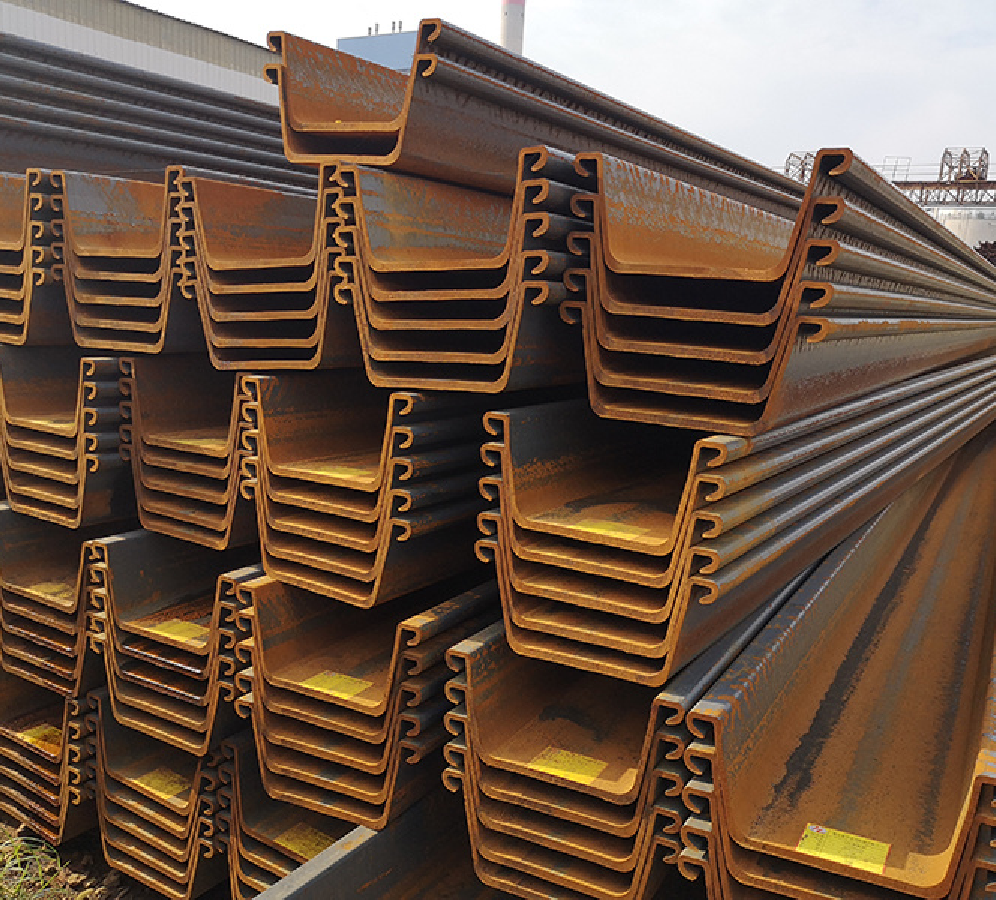

U and Z Type Sheet Piling Wall

High modulus wall

Concrete wall

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our custom services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.