Welded Seam Steel Pipes LSAW

Longitudinal Submerged-Arc Welded Steel Pipe

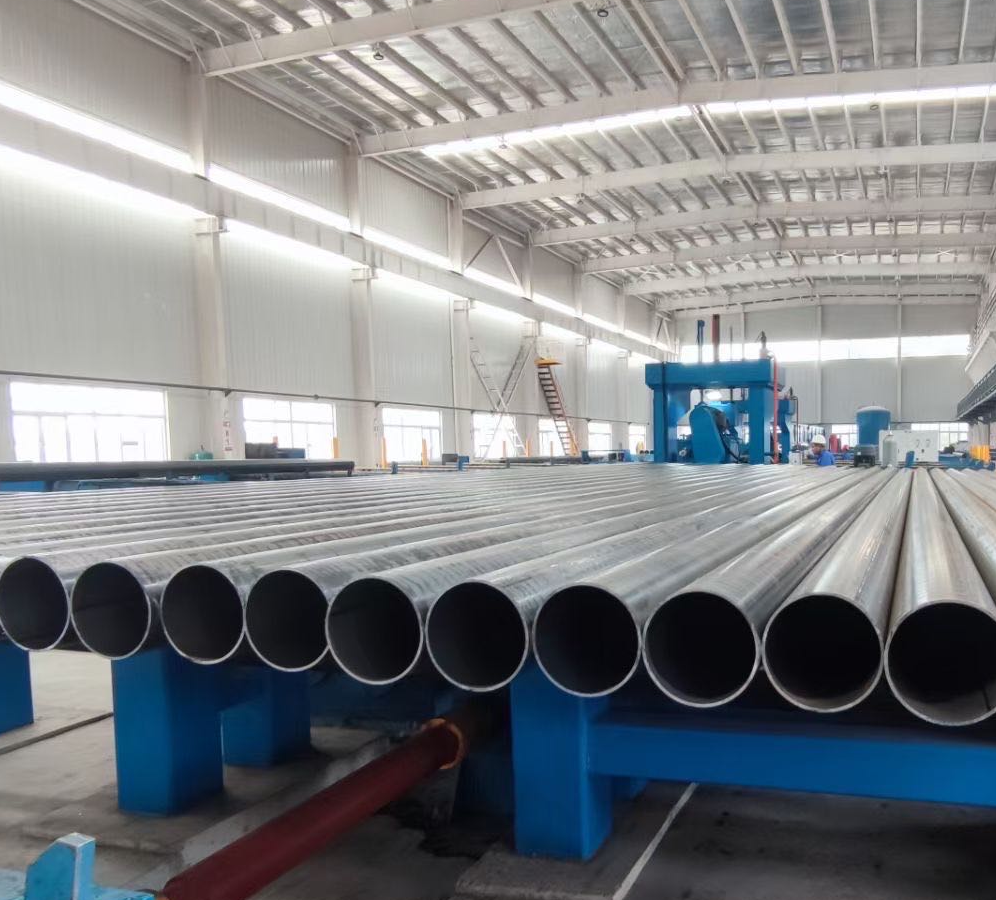

LSAW (Longitudinal Submerged Arc Welded) pipes or welded seam steel pipes are high-strength welded pipes used in oil and gas, construction, and various industries requiring high-pressure resistance and long-distance transport. Manufactured through submerged arc welding (SAW), it ensures high dimensional accuracy, corrosion resistance, and exceptional structural integrity.

The LSAW manufacturing process involves preparing steel plates (steel sheets), bending, seam welding, and heat treatment, resulting in a strong and precise weld seam.

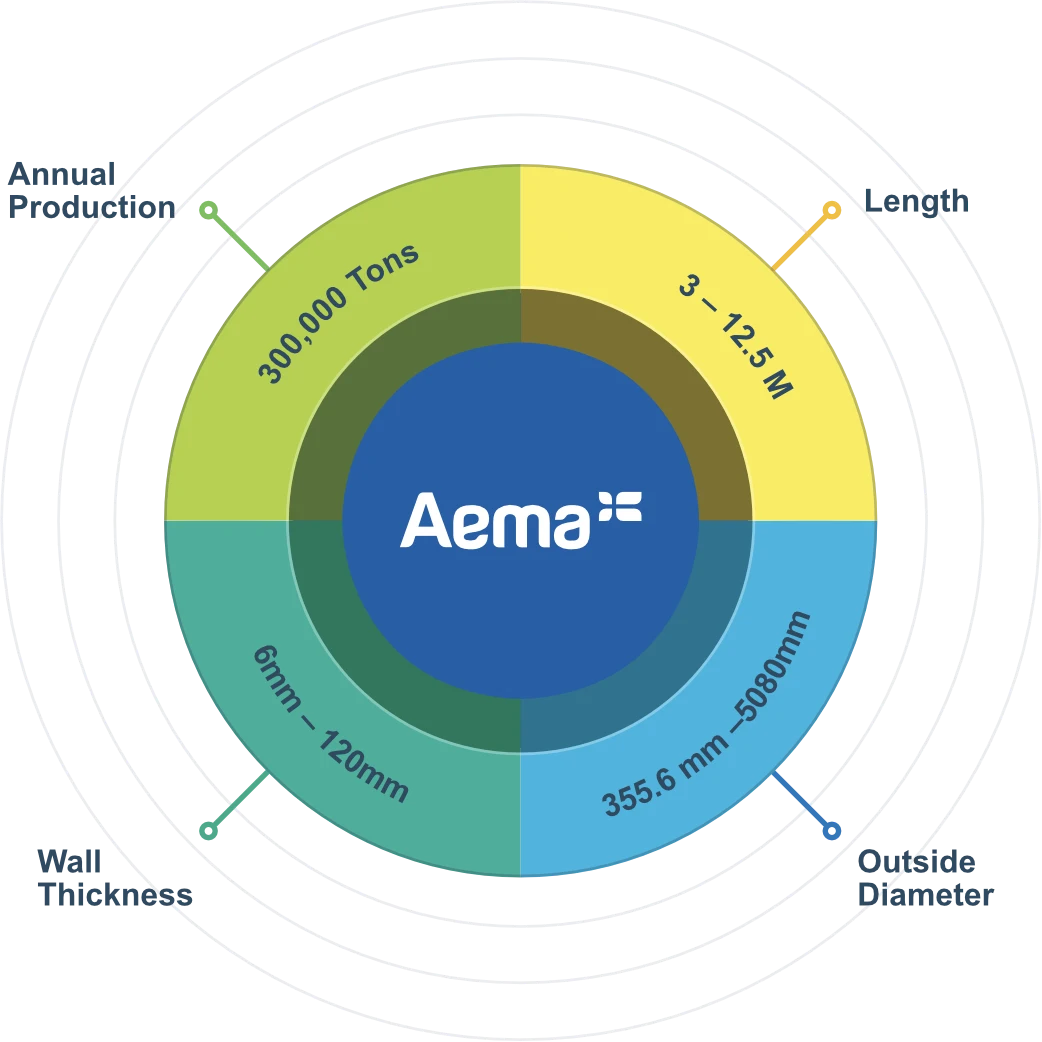

Out Diameter: 355.6 mm –5080mm

Wall Thickness: 6mm – 120mm

Length: 3 – 12.5 M

Standard Compliance: ASTM 53 / EN10217 / DIN 2458 / IS 3589 / GB/T3091 / GB/T9711

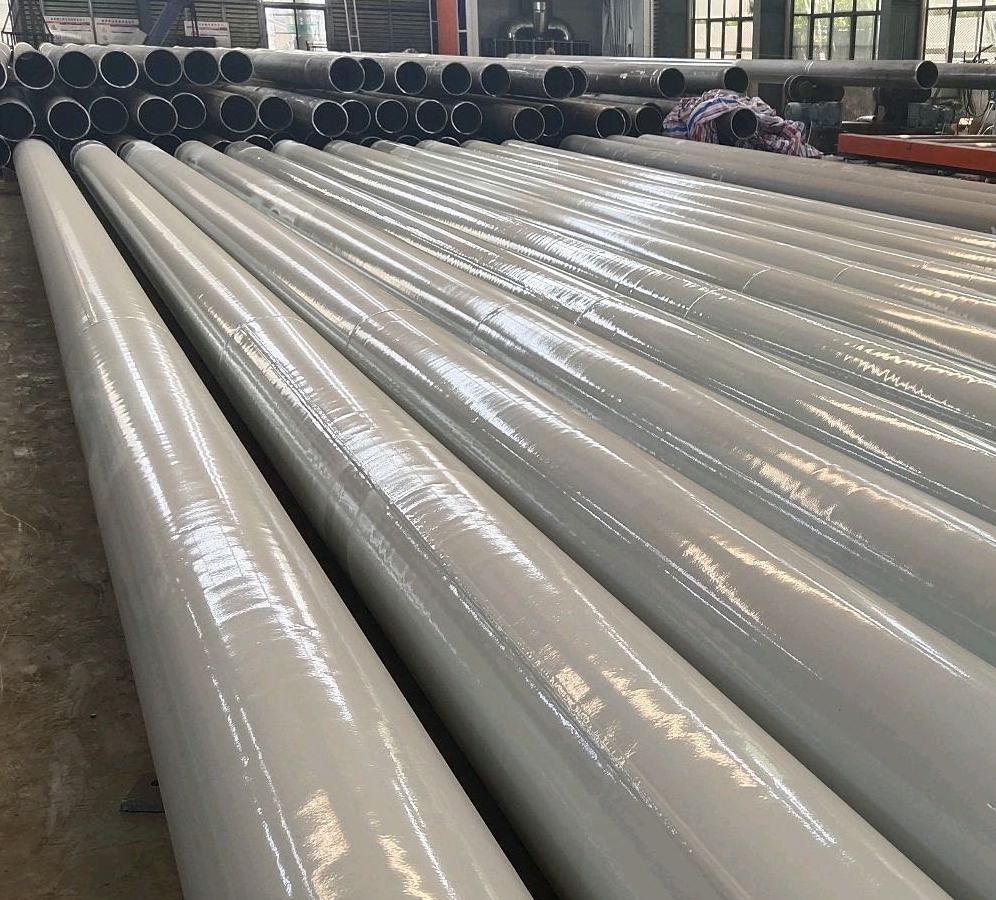

Surface Treatments: Fusion Bond Epoxy Coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil Coating.

Note: Custom surface treatments available upon request.

Terms of Supply and Payment Schedule

Considering the manufacturing and delivery times from our exclusive global partners, which might take as long as 30 – 90 days, we offer flexible payment terms including:

- A minimal advance payment for order confirmation.

- Flexibility to pay after the products are delivered to your warehouse or construction site.

- Up to 90 days installment plans or deferred payments are available.

Steel Structures and Custom Steel Fabrication Services

Design of sheet piles, pipe piles and H beams walls

Our tailored selections of type, specification and grade of sheet piles, pipe piles, and H beams (or their combination) ensure optimal profiles, weight, and the number of driving operations. Each solution is engineered and designed to balance cost-effectiveness, durability, quality and logistics.

![]()

Factory production of steel structures and welding

Our customised services of manufacturing metal structures and parts of structures and steel welding provide optimised design solutions tailored to specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct a comprehensive analysis to optimise your expenses, ensuring cost-effective delivery and on-site assembly of metal structures. By evaluating cargo plans, hard-to-reach locations and hidden connections, we optimise the process from procurement to installation on-site.