As environmental concerns, cost efficiency, and ease of handling gain importance in infrastructure and marine construction, plastic sheet piles have become an attractive alternative to traditional timber piling and even steel sheet piling. Plastic sheet pile installation has become a popular solution for erosion control, fluid containment, and water management in residential, commercial, and industrial projects. Made from materials such as vinyl (PVC sheet piles), HDPE, or synthetic blends, these corrosion-resistant systems offer long-term durability with minimal environmental impact.

This guide explores essential techniques and best practices for installing plastic sheet piles, ensuring structural integrity, performance, and long-term satisfaction in erosion control, flood protection, and water control structures.

Introduction: The Growing Role of Plastic Piling Systems

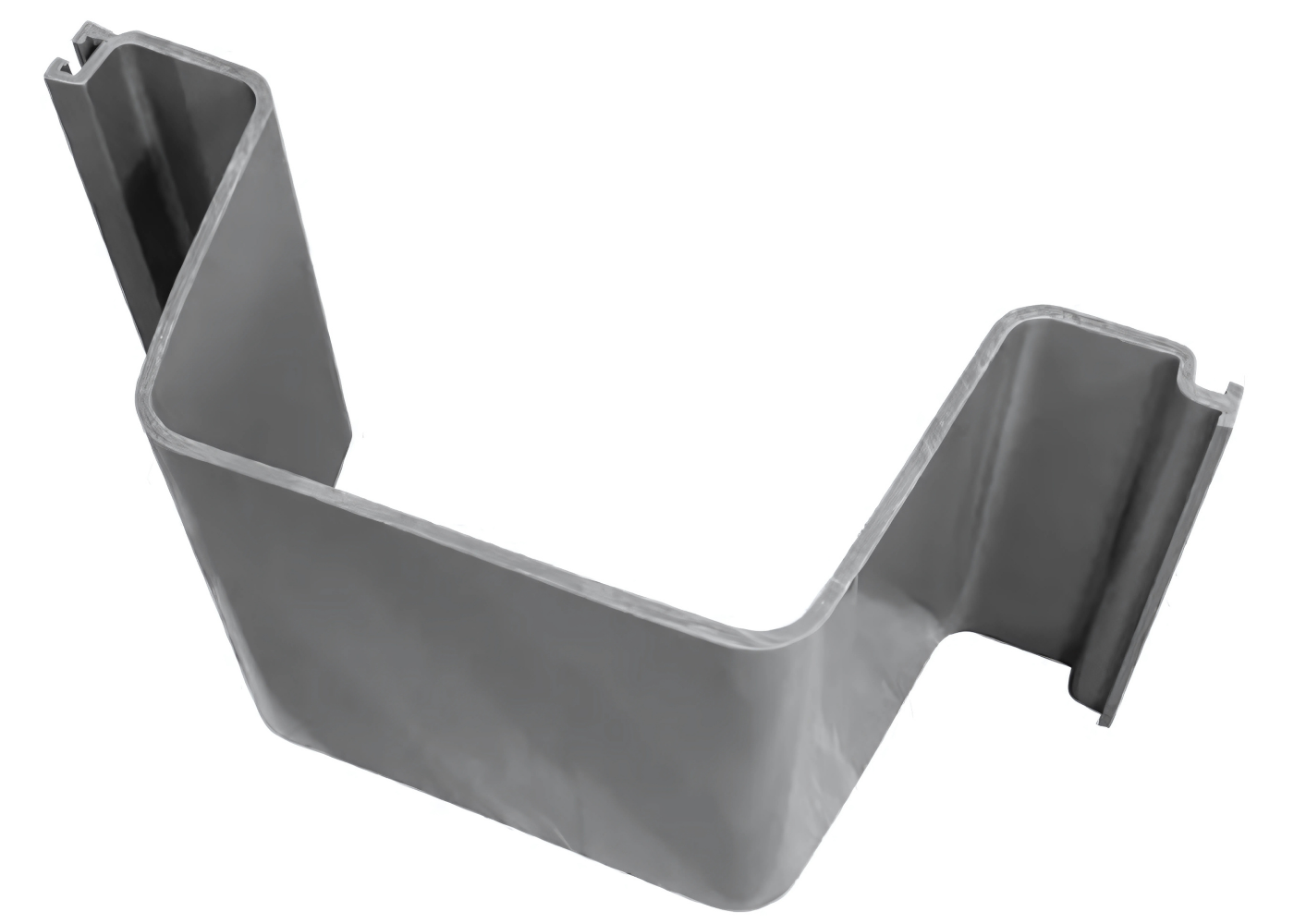

Plastic sheet piling is no longer limited to lightweight or temporary installations. Modern vinyl sheet piling offers high structural performance and superior corrosion resistance, especially in marine environments where steel or wood would degrade over time. These synthetic sheet piles are commonly used in:

- Flood protection and shoreline reinforcement

- Seawalls and shoreline protection

- Cut-off walls for groundwater control

- Canal lining and riverbank stabilisation

- Peatland restoration and fluid containment

- Foundation structures near water bodies

- Marine structures, including docks, embankments, and ports

Among available options:

- Vinyl sheet piles (PVC-based): High UV resistance, dimensional stability, suitable for marine and flood control projects.

- HDPE sheet piles: High flexibility, chemical resistance, used in landfills, mining, and aggressive soils.

- Composite piles: Blended materials that offer specific strength and chemical resistance profiles.

Each system brings unique advantages depending on soil conditions, exposure, and design life requirements.

Site Preparation

Proper site evaluation and thorough preparation of the job site are vital to ensure effective and long-lasting results:

Soil Testing and Ground Conditions

- Geotechnical investigations should determine soil type, compaction, water table level, and presence of obstructions.

- Cohesive clay and silty soils may require pre-drilling, whereas sandy or loose soils are more suitable for driving methods.

Understanding ground conditions, such as soil type, water table levels, and obstructions, helps determine the required pile profile and length, as well as the optimal installation method (e.g., vibration, jetting) and anchoring system.

Selecting the Right Material

- Use vinyl (PVC material) piles for superior UV resistance and minimal leaching, making them ideal for marine structures.

- Select HDPE or composite options when flexibility or chemical resistance is a priority.

Installation Methods

Depending on soil type, environmental sensitivity, and project scale, various methods are used:

Driving method

- Vibratory Driving: Most commonly used for vinyl sheet pile installation, this method utilises vibratory hammers mounted on excavators. Efficient in soft to medium-dense soils and granular soils with low obstruction levels.

- Impact Driving: Utilised in dense or compact soils, impact driving enables the insertion of piles with greater force. However, care must be taken to avoid driving damage or cracking, especially in rigid plastic piles.

Jetting

- Water jetting systems help loosen soil around the pile tip, improving drivability in cohesive or resistant layers.

Trenching or Pre-Drilling

- In rock, dense clay, or fill material, pre-trenching or boring holes can allow precise placement without damaging the pile material.

Driving Tips:

- Avoid excessive force to prevent interlock deformation or pile breakage.

- Ensure verticality and alignment throughout the process.

Equipment and Safety

Efficient and safe installation depends on using the right tools and enforcing job site controls.

Machinery Requirements

- Small-scale projects (residential seawalls): Excavator with a vibratory plate or small mandrel

- Large-scale projects: Dedicated pile drivers with steel mandrels for stability and precision

Worker Protection

- PPE for noise, UV, and vibration exposure

- Stability checks for machinery near water

- Adherence to environmental handling guidelines to avoid spillage or contamination

Anchoring and Structural Support

Proper structural reinforcement is essential, especially in flood protection or foundation structures:

- Deadman anchors: Used behind the wall to resist soil pressure

- Tie rods: Connect the anchor and sheet pile wall

- Waling beams: Distribute the load evenly along the wall face

For critical water control structures, these supports are indispensable for ensuring long-term performance and preventing deflection or failure. The anchoring system should be chosen based on the wall height, expected surcharge, and groundwater conditions.

Common Installation Mistakes

Avoiding these common errors will reduce long-term maintenance and structural issues:

- Driving damage: Excessive force during pile driving can split or deform plastic piles

- Misalignment: Poor interlock alignment results in gaps, leaks, and reduced load capacity

- Spacing errors: Incorrect spacing or inconsistent embedment depth leads to instability

Use laser alignment tools and guide templates during installation to ensure accuracy.

Post-Installation Checks

After installation, conduct thorough checks to confirm structural integrity and performance:

Deflection Measurement

- Monitor wall straightness and deflection under static or tidal loads.

- Ensure the wall meets project tolerances and does not show signs of bowing or rotation.

Connection and Cap Inspection

- Verify tight interlocks across the structure.

- Inspect top caps for secure placement and protective sealing.

Well-installed caps protect against harmful ultraviolet rays and offer an aesthetically finished appearance.

Conclusion

Plastic sheet pile systems have become an effective alternative for modern sheet piling solutions, especially when corrosion resistance, environmentally friendly materials, and long-term cost savings are priorities.

By understanding site requirements, material selection, and optimal installation techniques, contractors and engineers can deliver high-performance, cost-effective retaining solutions that stand the test of time.

Related Products from Aema Steel

- PVC Vinyl Sheet Piles

- Hot Rolled U Type Sheet Piles

- Hot Rolled Z Type Sheet Piles

- Steel Pipe Piles

- Welded H Piles

Contact us today to receive a tailored offer for your upcoming project.