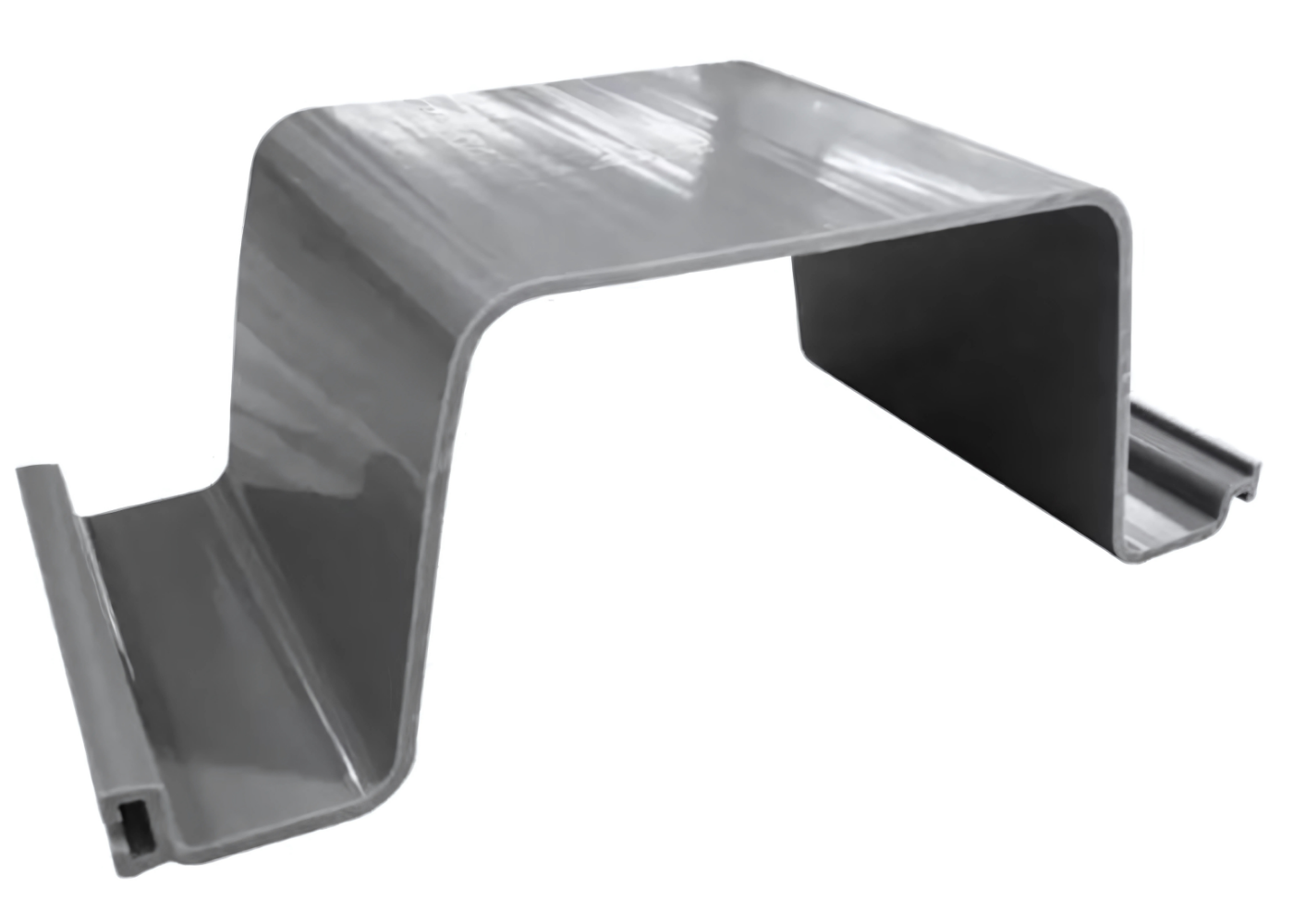

Vinyl sheet piling and PVC sheet piles are frequently mentioned interchangeably in marine construction, erosion control, and fluid containment projects. However, subtle differences in terminology, manufacturing blends, and performance characteristics can influence your project outcomes. This article explores the distinctions between vinyl and PVC sheet piles, clarifies the terminology, and compares material properties to help engineers, contractors, and developers choose the most effective synthetic sheet piling solution for their specific application

Are Vinyl and PVC Sheet Piles the Same?

At first glance, the terms seem synonymous. After all, vinyl is derived from polyvinyl chloride (PVC) — the base polymer used in both product types. However, not all PVC sheet piles are created equal. Variations in formulation, additives, and manufacturing processes can lead to substantial differences in performance, longevity, and suitability for specific site conditions.

- Vinyl sheet piles typically refer to products with a higher purity PVC content, designed for long-lasting structural applications, such as marine structures, seawalls, and erosion control barriers.

- PVC sheet piles may sometimes contain blended materials or additives tailored to specific applications, such as water control systems, fluid containment projects, or temporary retaining walls.

The distinction can impact properties such as chemical resistance, UV performance, and cost efficiency.

Material Comparison:

1. Pure Vinyl vs. PVC Blends

Vinyl is a common term used to describe extruded sheet piles made from polyvinyl chloride. But depending on the manufacturer, the PVC used may be:

- Pure rigid PVC (uPVC): offers high stiffness, UV stability, and excellent dimensional consistency, making it ideal for structural marine use.

- Modified PVC blends: May include plasticisers or fillers that enhance flexibility or reduce production costs, but these additions can also lower mechanical strength and chemical resistance.

The selection of resin, pigments, and stabilisers determines the sheet pile’s mechanical properties, weather resistance, and service life. Top-tier products use virgin or high-grade recycled PVC with UV inhibitors for long-term outdoor durability.

2. Structural Properties

- Tensile Strength: Both materials provide sufficient strength for low- to medium-load applications. Pure vinyl often exhibits greater rigidity, ideal for foundation structures exposed to hydrostatic pressure.

- UV Resistance: One key advantage of vinyl is its ability to resist harmful ultraviolet rays, making it a more long-lasting structural solution for sunny or tropical climates.

- Dimensional Tolerances: Certified vinyl profiles are produced with strict dimensional tolerances, offering better consistency for modular construction and sealing membrane compatibility.

Factors to Consider:

When evaluating vinyl sheet piling, it’s important to consider:

- Tensile and flexural strength: Key for resisting lateral soil and water pressure in retaining wall applications.

- UV resistance: Ensures colour retention and prevents brittleness over time, especially critical in sun-exposed environments.

- Creep resistance: Enables the material to sustain a load without experiencing long-term deformation.

- Chemical resistance: Ideal for use in saltwater, brackish water, and contaminated soils where steel or wood may degrade.

PVC sheet piles typically maintain consistent product quality across batches, with tight manufacturing tolerances and predictable performance even in the most extreme conditions.

Performance in Real-World Applications

- Flexural Strength and Retaining Capacity: Vinyl sheet piling offers high flexural strength, making it well-suited for retaining walls and marine construction projects where soil pressure or wave action is significant. These structures remain stable even in water control environments with varying tide levels.

- Corrosion and Chemical Resistance: Compared to steel or traditional materials like wood, vinyl/PVC products exhibit superior chemical resistance. They are highly resistant to small molluscs, crustaceans, algae, and other marine biofouling, which frequently degrade wooden solutions or corrode sheet pile structures. Vinyl’s inert material composition also resists paint chips, ensuring longer-term visual appeal.

Installation and Handling Differences

While both vinyl and generic PVC sheet piles are lightweight and corrosion-resistant, performance in the field can differ due to:

- Weight and drivability: High-quality vinyl sheet piling is often lighter yet stiffer, making it easier to install with vibratory hammers or compact excavators.

- Thermal expansion: Some blends may deform in extreme heat if not installed with proper expansion gaps.

- Ease of handling on-site: Vinyl’s smooth surface and consistent interlocks simplify installation, reducing labour time.

Overall, the installation process for vinyl sheet piling is more efficient, with fewer breakages and alignment issues compared to low-grade PVC alternatives.

Environmental Impact and Certifications

With increasing demand for green construction, vinyl sheet piles are gaining attention for their:

- Recyclability: Many products contain post-industrial or post-consumer recycled content.

- Non-leaching formulation: Quality vinyl formulations do not release harmful substances into the surrounding soil or water.

- Green certifications: Certain PVC sheet piles contribute points toward LEED certification or other environmental building standards when produced by certified manufacturers.

When sourced responsibly, vinyl sheet piling can be part of a sustainable construction approach for waterfront protection or peatland restoration.

Cost and Availability

Cost can vary greatly depending on:

- Resin formulation and UV inhibitors

- Wall thickness and profile geometry

- Country of origin and freight costs

- Minimum order quantities or custom manufacturing needs

While PVC sheet pile may sound like the economical option, cheaper blends can fail significantly sooner, increasing lifecycle costs. On the other hand, premium vinyl sheet piling may offer a lengthy warranty period, delivering better long-term value.

While steel sheet piles are still the preferred solution for high-load applications, vinyl pvc sheet piles are gaining ground in coastal, canal, and low-load marine construction due to their long-term cost savings.

Which to Choose? Use Case Scenarios

|

Application |

Preferred Option |

Why |

|---|---|---|

|

Residential seawalls |

Premium vinyl sheet piling |

Long lifespan, consistent appearance, safe for pets/kids |

|

Marinas and docks |

High-grade uPVC |

Marine borers resistance, UV durability |

|

Peatland barriers |

Certified vinyl sheet pile with gaskets |

Low permeability, climate benefits |

|

Temporary flood protection |

Economical PVC blends |

Lightweight and reusable |

|

Heavy-duty commercial projects |

Reinforced vinyl profiles |

Structural strength and custom anchoring options |

Conclusion

Not all plastic sheet piles labelled “PVC” are created equal. The term “vinyl” typically refers to higher-grade, marine-grade PVC products engineered for long-lasting performance, chemical resistance, and structural integrity. When evaluating options for your vinyl seawall project, the real measure of quality lies in material formulation, manufacturing consistency, and application-specific performance.

Whether you are working on delivering sheet piling solutions or comparing options, vinyl and PVC materials, when compared to steel, offer numerous advantages worth considering, especially when longevity, corrosion resistance, and easy installation are key priorities.

Related Products from Aema Steel

- PVC Vinyl Sheet Piles

- Hot Rolled U Type Sheet Piles

- Hot Rolled Z Type Sheet Piles

- Steel Pipe Piles

- Welded H Piles

Contact us today to receive a tailored offer for your upcoming project.