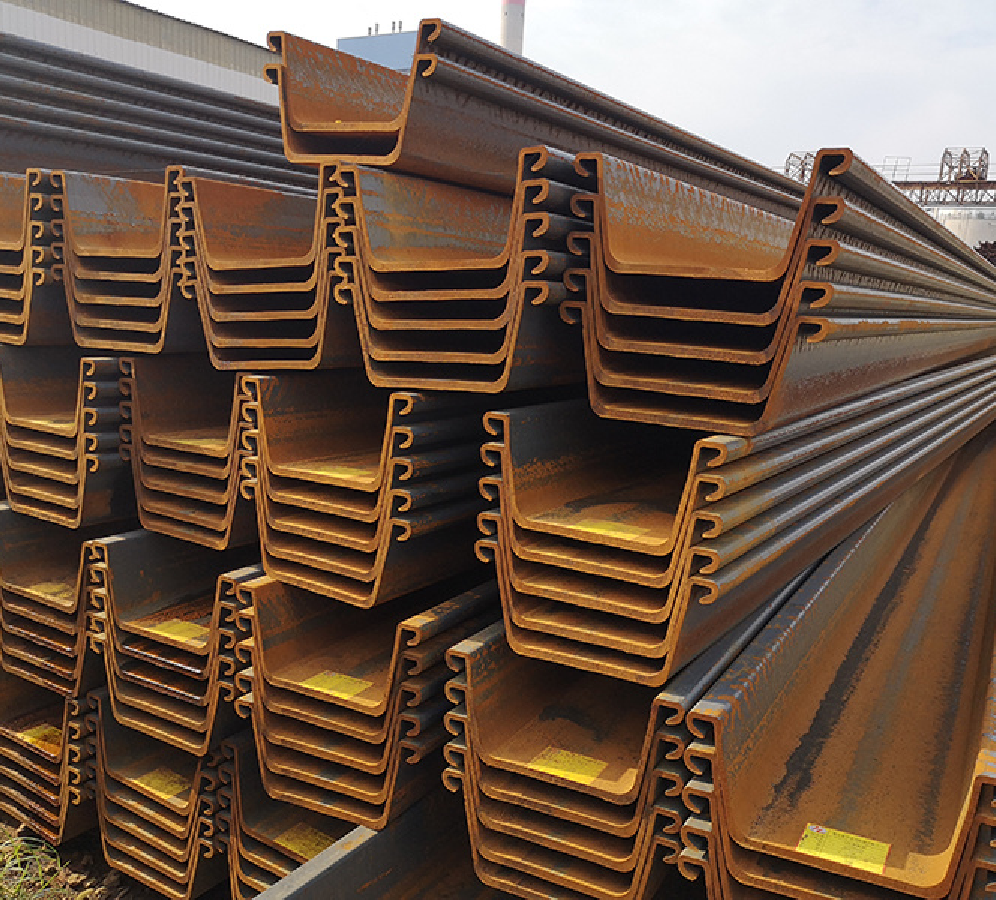

Corner Sections / Connectors

Our connectors are made from the highest steel grades S355 and S430 and crafted for high-tensile structural applications. We offer these high-performing connectors in various types, sizes, lengths, and coatings—all following industry standards. Hot rolled and cold rolled corner sections are available and we can supply the different types of connectors according to your project requirements.

Advantages

High-grade S355 and S430 steel ensures strong and durable components. The materials grade is known for their next-level tensile strength to withstand high structural loads. This also reduces the need for frequent replacements and maintenance.

Built to meet strict international standards, guaranteeing consistent quality and performance. This adherence to industry benchmarks ensures confidence and reliable results in all structural applications for global safety.

Optimised for ease of assembly and welding, our connectors help cut down on construction time and labour costs, especially in large-scale projects where efficiency is paramount.

Terms of Supply and Payment Schedule

Considering the manufacturing and delivery times from our exclusive global partners, which might take as long as 30 – 90 days, we offer flexible payment terms including:

- A minimal advance payment for order confirmation.

- Flexibility to pay after the products are delivered to your warehouse or construction site.

- Up to 90 days instalment plans or deferred payments available.

Specifications

| Name | Type | Steel grade | Steel thickness (mm) | Dimension (mm) | Weight (kg) |

|---|---|---|---|---|---|

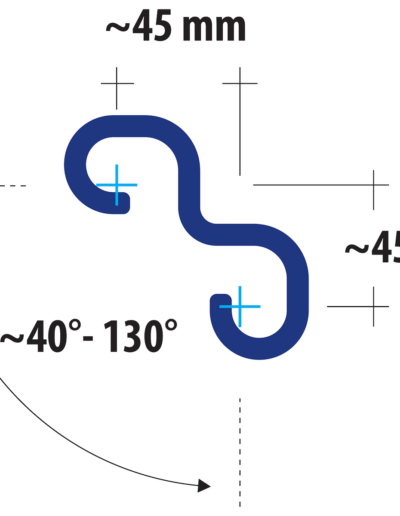

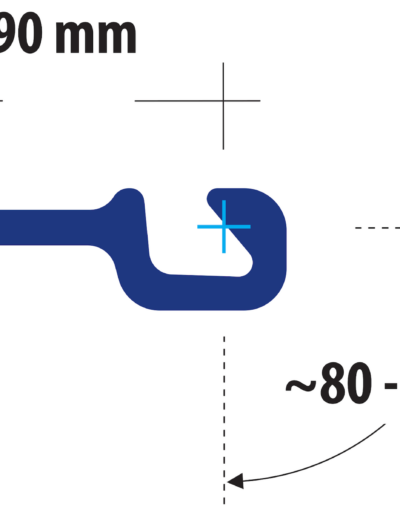

| Ultra S | Corner connector | S355 | 9 | 11.8 | 25.3 |

| LV20n | Corner connector | S355 | 8 | 11.8, 14, 18 | 14.07 |

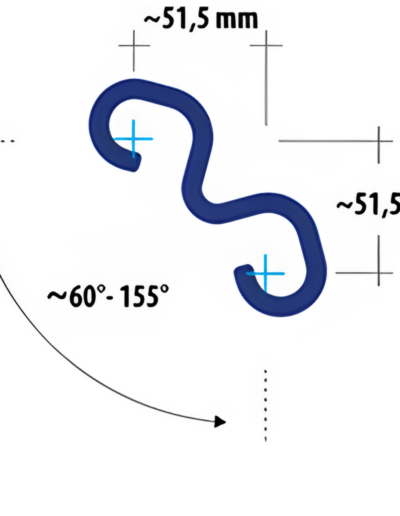

| LLS90 | Corner connector | S355 | 9 | 8, 11.8 | 17.66 |

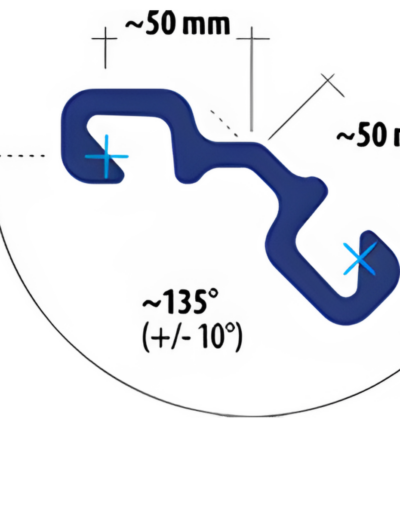

| LLS135 | Corner connector | S355 | 9 | 8, 11.8 | 17.66 |

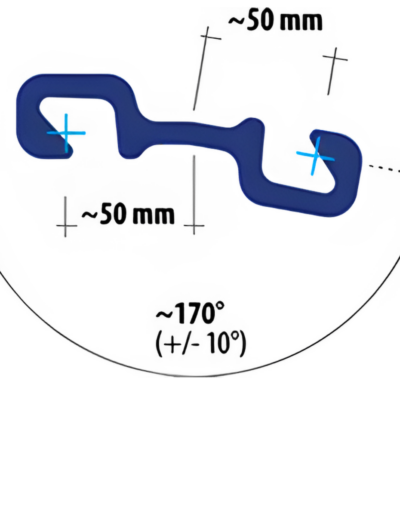

| LLS170 | Corner connector | S355 | 9 | 8, 11.8 | 17.63 |

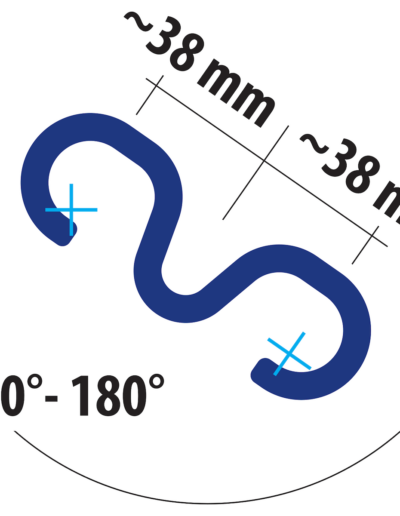

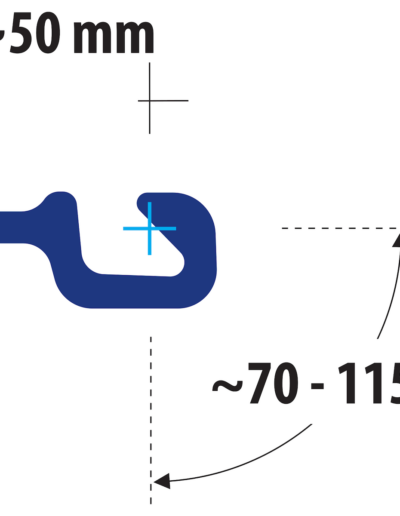

| LV-Omega | Corner connector omega | S355 | 8 | 11.8, 13.4 | 14.04 |

| LVO | Corner connector omega | S355 | 8 | 11.8, 13.4 | 13.85 |

| LVOn | Corner connector omega | S355 | 8 | 11.8, 13.4 | 13.91 |

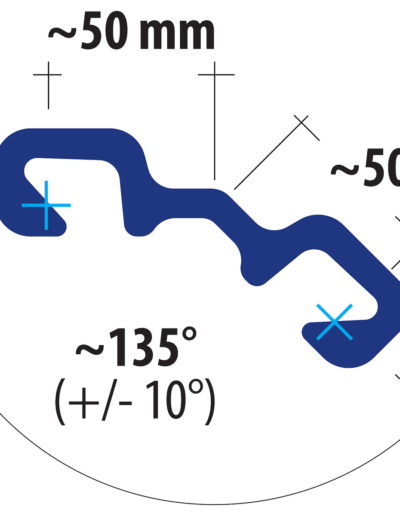

| LLO135 | Corner connector omega | S355 | 9 | 11.8, 13.4 | 17.60 |

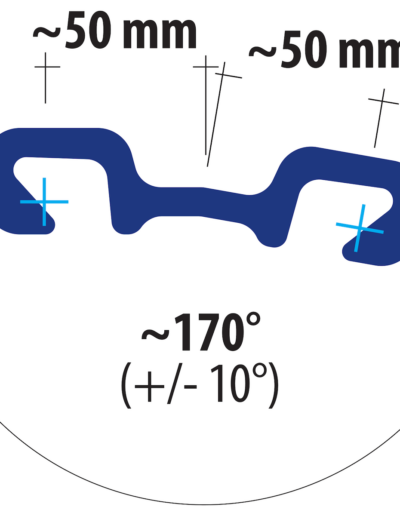

| LLO170 | Corner connector omega | S355 | 9 | 11.8, 13.4 | 17.60 |

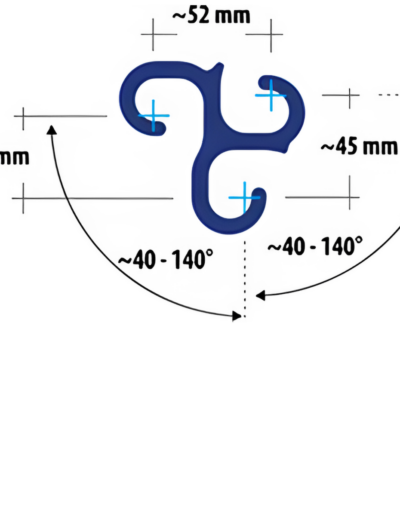

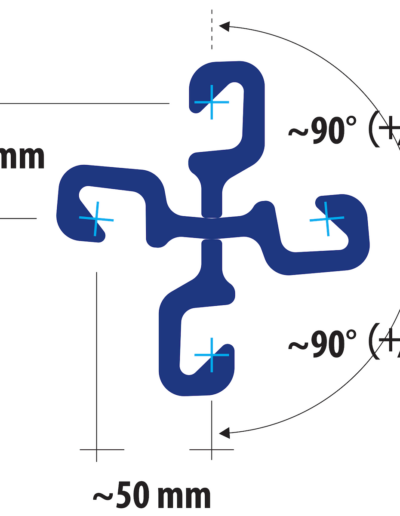

| LTn | T-connector | S355 | 8 | 11.8, 13.8 | 15.50 |

| LLTS | T-connector | S355 | 9 | 10.8 | 26.2 |

| LLTS ma | T-connector | S355 | 9 | 10.8 | 27.00 |

| LOTn | T-connector | S355 | 8 | 11.8, 13.8 | 17.20 |

| LLTO | T-connector | S355 | 9 | 10.8 | 26.20 |

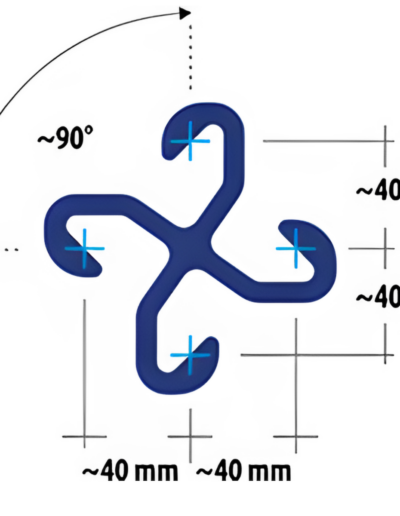

| L4S | Cross profile | S355 | 8 | 11.8 | 23.20 |

| LL4S ma | Cross profile | S355 | 9 | 11.8 | 36.00 |

| LPB100-9A | Weld-on connector | S355, S430 | 9 | 8, 11.8 | 9.05 |

| LPB180-10 | Weld-on connector | S355, S430 | 10 | 8, 11.8 | 12.94 |

| LV22 | Weld-on connector | S355 | 8 | 11.8 | 8.02 |

| L8/E22 | Weld-on connector | S355 | 9.5 | 11.8 | 8.47 |

| CF90 | Corner & weld-on profile | S355 | 8 | 13.45 | 17.50 |

| CF-Junction | Corner & weld-on profile | S355 | 8 | 11.8 | 8.87 |

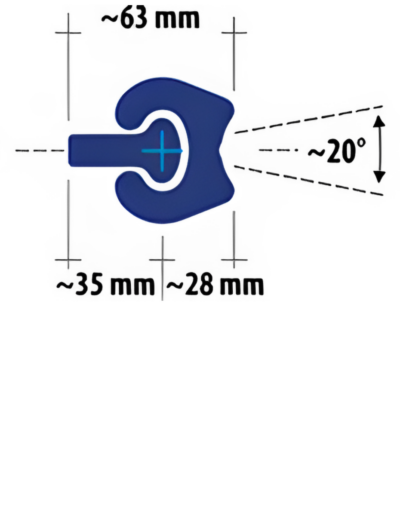

| MF63 | Connector for Pipe Pile walls | S355 | 12 | 8, 11.8 | M35: 4.76 |

| MF75 | Connector for Pipe Pile walls | S355 | 12 | 8, 11.8 | M35: 4.76 F40: 14.28 |

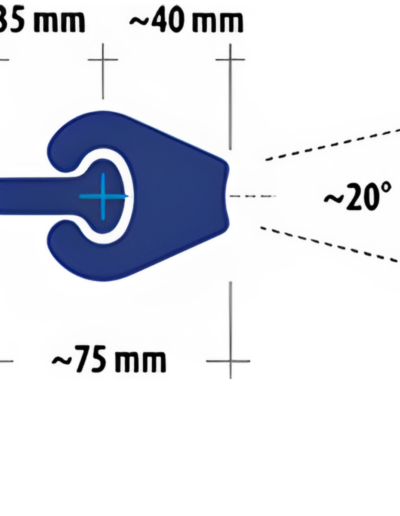

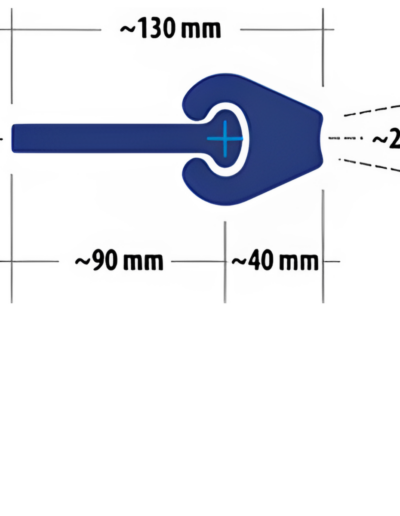

| MF130 | Connector for Pipe Pile walls | S355 | 12 | 8, 11.8 | M90: 9.76 F40: 14.28 |

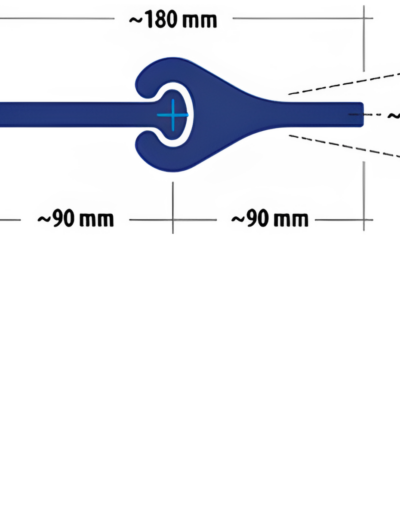

| MF180b | Connector for Pipe Pile walls | S355 | 12 | 8, 11.8 | M90: 9.76 F90: 18.42 |

| FD180 | Connector for Pipe Pile walls | S355 | 12 | 8, 11.8 | 17.42 |

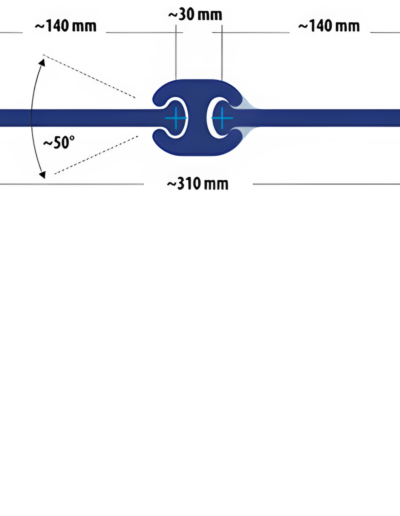

| MDF310 | Connector for Pipe Pile walls | M: S355 DF: S430 |

12 | 8, 11.8 | M140: 14.77 DF: 14.62 |

Swipe

Note: The above specification is only a part of all the sizes, more sizes are available to suit specific project needs. Contact us for detailed information and customized solutions

Customised Solutions and All-range Fabrication Services

Custom Design and Rental of Sheet Pile and Tubular Pile Walls

Our tailored selections of type and grade of sheet pile/tubular pile (or their combination) ensure an optimal profile, weight, driving, and extraction.

While rental calculations take into account hidden effects like waste/damage to offer the best balance of price, quality, physical characteristics and performance.

![]()

Factory production of metal structures and welding

Our custom services of manufacturing steel structures and welding are geared to address the specific needs of your maritime and energy projects.

We ensure the design solutions are optimised for specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct the analysis and optimise your expenses to help you save money on delivering and assembling metal structures on-site, considering hard-to-reach locations and hidden connections , ensuring everything is efficient and cost-effective.