Products

Combined walls design

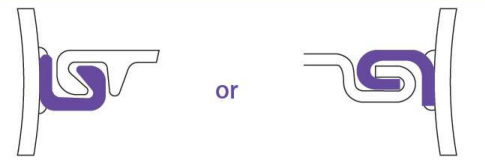

Combined wall with tubular piles consists of tubular piles, sheet pile interlocks or sheet piling clutches and sheet piling. Sheet pile connectors are welded along the length of tubular pipes, full length or partial length. The tubular combined wall not only service as the retaining wall member, resisting horizontal loads, but also serve as bearing pile which resist vertical loads. Nowadays the interlocks used in the combined piles have many choices on the market, C9 C14 are the most traditional sheet piling accessory.

Adventages

We will choose the best and most economical solutions for you. Sometimes combined walls with tubular piles is not the most economical solutions.

No limit on dimensions, or steel grade. This is especially important in deep foundations, cofferdams, land reclamation, Jetty constructions, Wharf construction, sheet pile dewatering.

Special corners sections can also be made on request. Future fabrications, like painting, welding, etc, can be also made upon request.

Advantages:

- We will choose the best and most economical solutions for you. Sometimes combined walls with tubular piles is not the most economical solutions.

- No limit on dimensions, or steel grade. This is especially important in deep foundations, cofferdams, land reclamation, Jetty constructions, Wharf construction, sheet pile dewatering.

- Special corners sections can also be made on request. Future fabrications, like painting, welding, etc, can be also made upon request.

Terms of Supply and Payment Schedule

Considering the manufacturing and delivery times from our exclusive global partners, which might take as long as 30 - 90 days, we offer flexible payment terms including:

- A minimal advance payment for order confirmation

- Flexibility to pay after the products are delivered to your warehouse or construction sit

- Up to 90 days instalment plans or deferred payments available

Specification

| Section | Dimensions | Mass | Moment of inertia | Modulus of Section | ||||

| Width | Height | Thickness | Per pile | Wall | ||||

| w | h | t | s | |||||

| mm | mm | mm | mm | kg/m | kg/m2 | cm4/m | cm3/m | |

| GPU 3-350a | 350 | 140 | 8 | 8 | 37.4 | 106.9 | 2073 | 296 |

| GPU 3-350b | 350 | 145 | 9 | 9 | 40.6 | 116 | 2263 | 323 |

| GPU 4-350 | 350 | 150 | 10 | 10 | 45.6 | 130.3 | 2460 | 351 |

| GPU 4-600 | 600 | 170 | 6 | 6 | 40 | 66.6 | 3719 | 443 |

| GPU 5-400 | 400 | 170 | 7 | 7 | 35.5 | 88.8 | 4321 | 502 |

| GPU 5-600a | 600 | 170 | 7 | 7 | 46.7 | 77.8 | 4386 | 516 |

Note: This table is only part of our sizes. We have over 1000 different sizes. Please contact us if your size is not in the above table.

Customised Solutions and All-range Fabrication Services

Custom Design and Rental of Sheet Pile and Tubular Pile Walls

Our tailored selections of type and grade of sheet pile/tubular pile (or their combination) ensure an optimal profile, weight, driving, and extraction.

While rental calculations take into account hidden effects like waste/damage to offer the best balance of price, quality, physical characteristics and performance.

![]()

Factory production of metal structures and welding

Our custom services of manufacturing steel structures and welding are geared to address the specific needs of your maritime and energy projects.

We ensure the design solutions are optimised for specific conditions of the site, loading and unloading operations, transport, storage, and large-module assembly.

Cost optimisation for delivery and assembly of metal structures

We conduct the analysis and optimise your expenses to help you save money on delivering and assembling metal structures on-site, considering hard-to-reach locations and hidden connections , ensuring everything is efficient and cost-effective.